Steel beam damping structure

A technology of steel beams and beams, applied in the direction of earthquake resistance, building components, building types, etc., can solve problems such as bending and breaking of beams, and achieve the effects of improving rigidity, prolonging service life, and avoiding bending or even breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

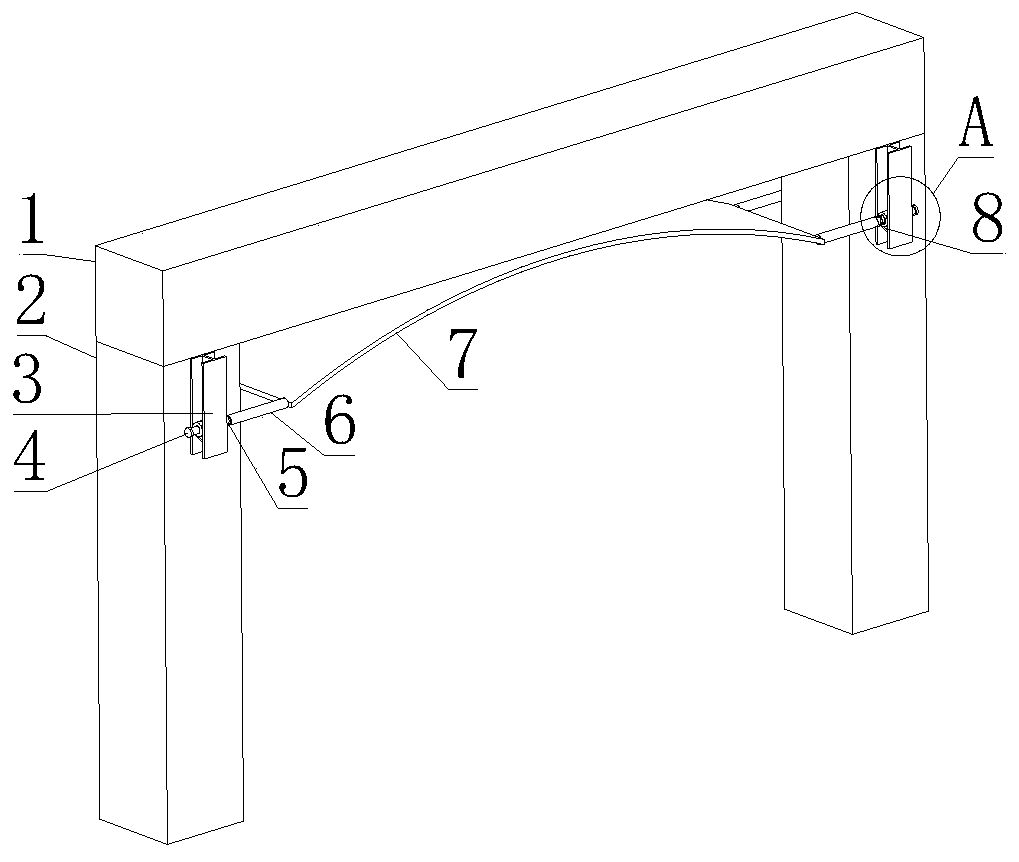

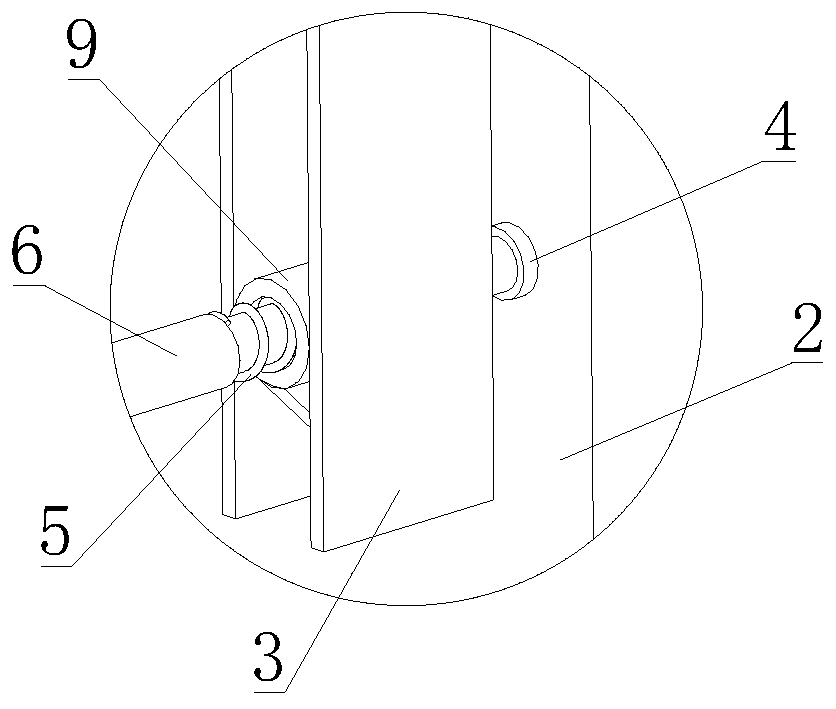

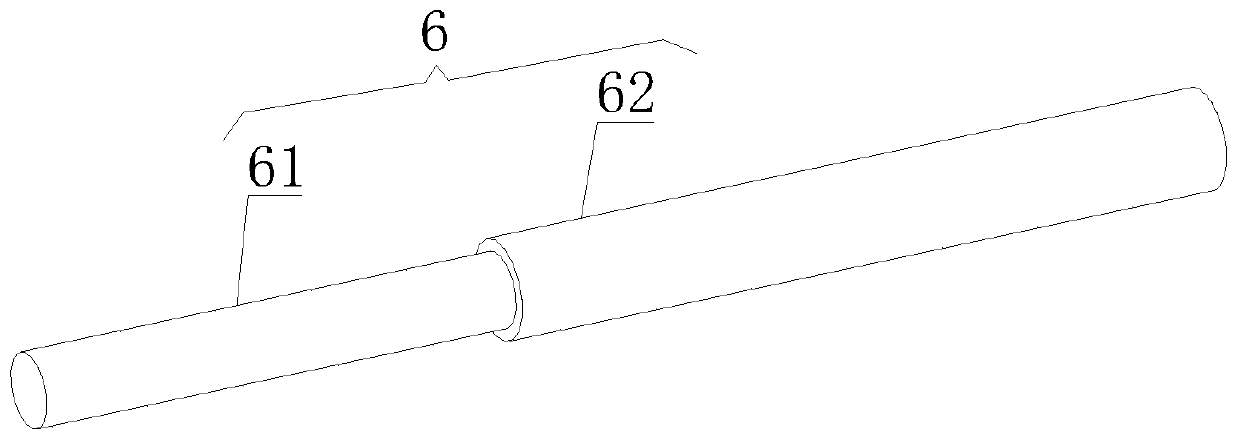

[0021] Such as Figure 1 to Figure 4 As shown, a steel beam damping structure according to the present invention includes a beam 1, a vibration damping assembly A and a vibration damping assembly B7, and the two ends of the beam 1 are welded with supporting columns 2, and the supporting columns 2 Supports 3 are fixedly installed on the front and rear sides of each support 3, and the damping assembly A is welded on each support 3. The damping assembly B7 is located on the lower side of the beam 1 and contacts the bottom surface of the beam 1. Both ends of the vibration assembly B7 are slidably connected to the vibration damping assembly A on the front and rear sides of the support column 2 through two guide rods 6 respectively. The beam 1 is damped by the damping assembly B7 and the damping assembly A. When in use, both the beam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com