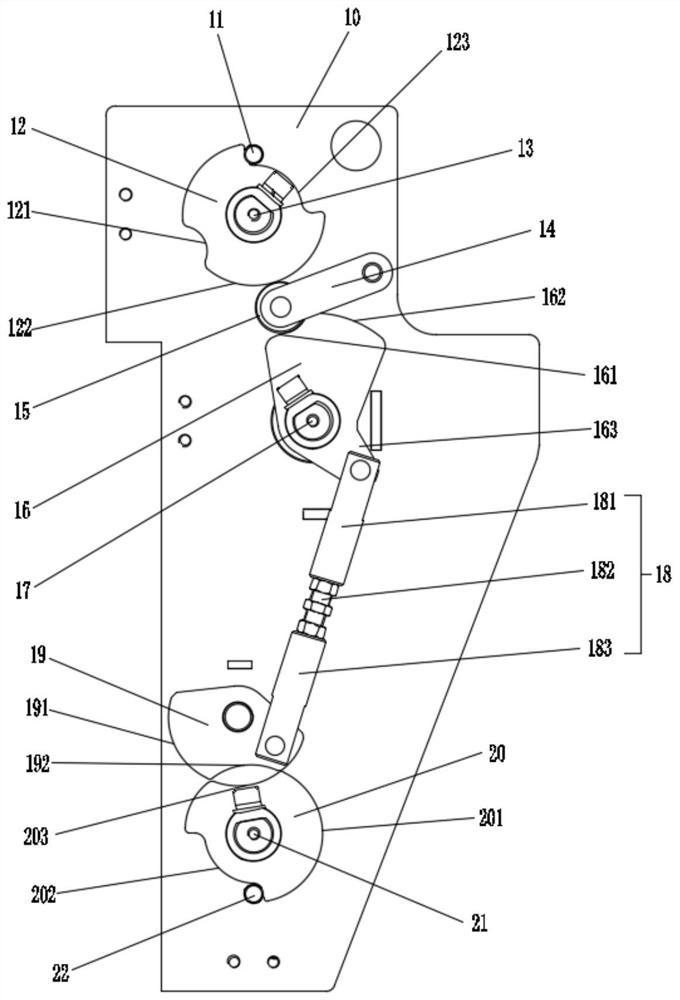

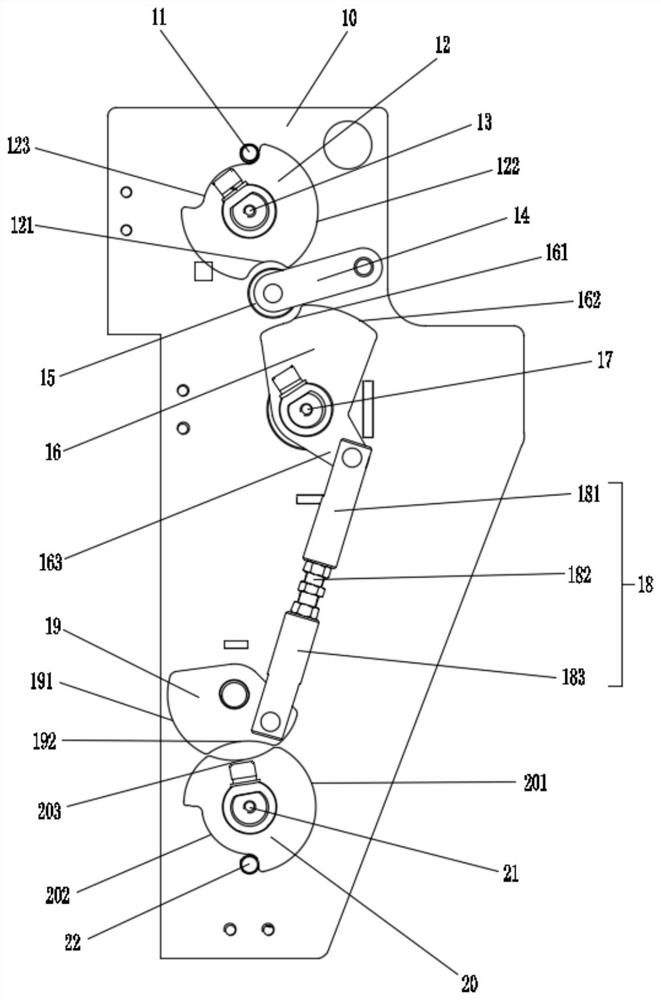

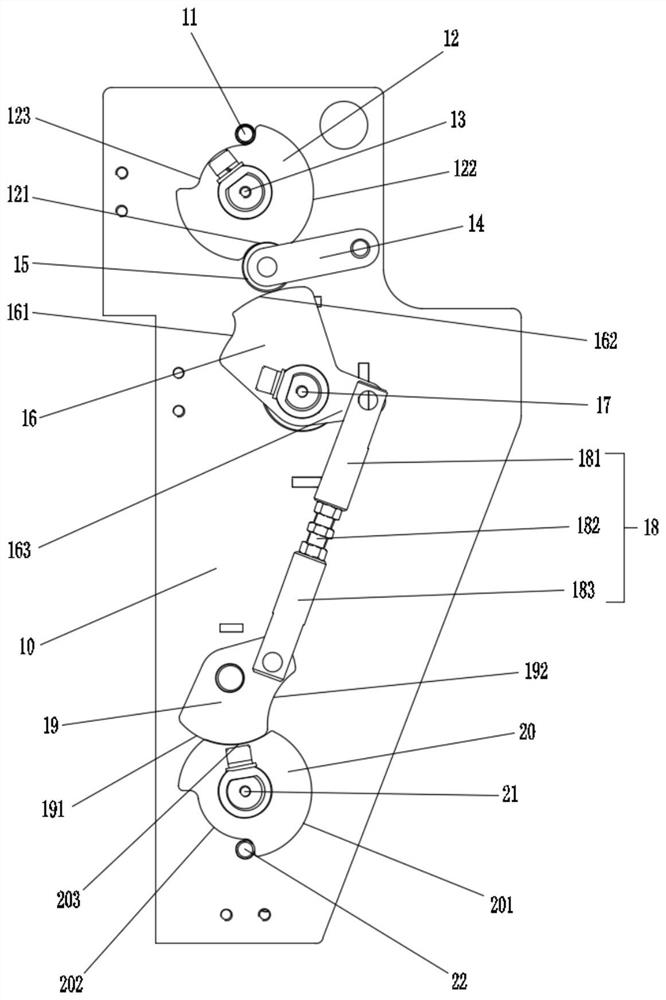

Forced interlock mechanism at the rear of the vacuum cabinet

An interlocking mechanism, behind-the-cabinet technology, applied in electrical components, electrical switches, circuits, etc., can solve problems such as operator misoperation, hidden dangers to personal safety, failure, etc., to avoid misoperation accidents, increase safety, components less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a further detailed description of the rear mandatory interlocking mechanism of the vacuum cabinet of the present invention in conjunction with the accompanying drawings and specific embodiments:

[0018] like figure 1 As shown, in this specific embodiment, the rear mandatory interlock mechanism of the vacuum cabinet of the present invention includes a rear plate 10, an isolation cam 12, an isolation main shaft 13, a circuit breaker cam 16, a circuit breaker main shaft 17, a grounding cam 20 and a grounding main shaft twenty one.

[0019] Back plate 10 is fixedly installed on the rear side wall of vacuum cabinet; Isolation cam 12 is fixedly installed on the isolation main shaft 13; shaft connection.

[0020] The circuit breaker cam 16 is fixedly installed on the circuit breaker main shaft 17; the circuit breaker main shaft 17 is located below the isolation main shaft 13, and passes through the back plate 10 to connect with the switch shaft (not shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com