A heavy-duty vehicle transmission control device

A technology for operating devices and gearboxes, applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., to achieve the effect of preventing accidental gearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

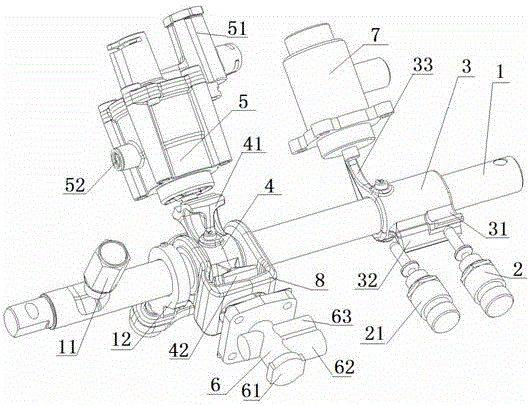

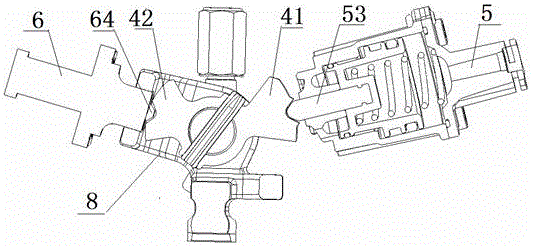

[0041] see figure 1 – figure 2 , a heavy-duty vehicle gearbox control device, comprising a gearbox selector shift shaft 1 and a neutral switch 2, said gearbox selector shift shaft 1 is sleeved with a selector shift dial 4 and a guide block sleeve 3, said The neutral guide block 31 fixedly connected on the guide block cover 3 is matched with the contact of the neutral switch 2; the transmission control device also includes a locking cylinder valve 5, a high-low gear switching control valve 6, a main box low-speed cut-off valve 7 and The reverse gear switch 21, the locking pin 53 of the locking cylinder valve 5 is in limited cooperation with the shifting head locking block 41 on the shifting head 4, the piston 64 of the high and low gear switching control valve 6 is in contact with the shifting head 4 The high and low gear switching control guide block 42 on the shifting head 4 is matched, and the shifting head locking block 41 and the high and low gear switching control guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com