Operation progress monitoring method and system

An operation and progress technology, which is applied in the control system of the transportation center, railway car body components, railway signals and safety, etc., can solve the problems of reducing operation efficiency, hidden dangers, and inability to realize operation supervision in the station, so as to improve the driving safety, The effect of avoiding major hidden dangers and improving the efficiency of work completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

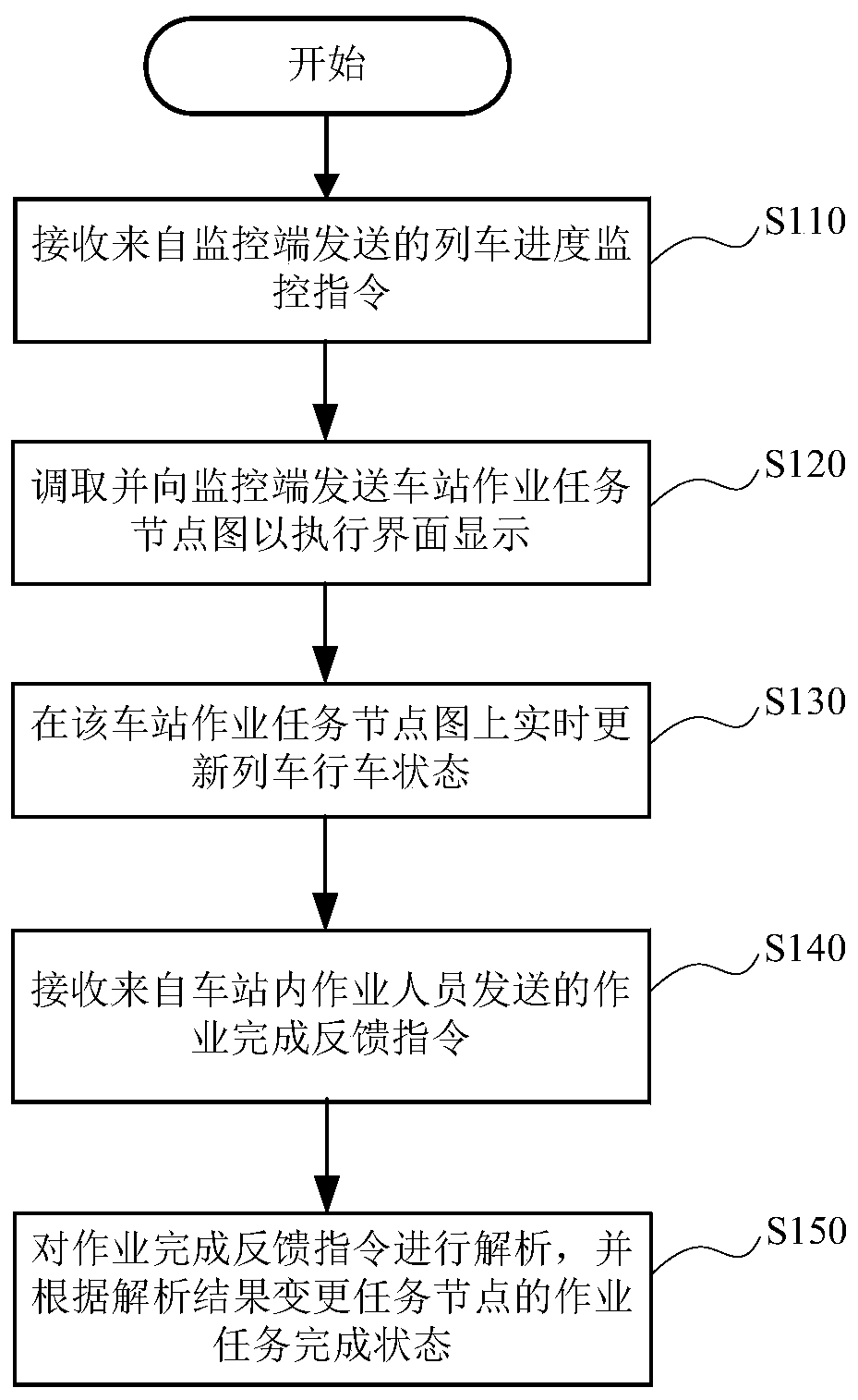

[0031] figure 1 It is a schematic flow chart of the operation progress monitoring method for monitoring the operation in the railway station according to the first embodiment of the present application. Refer below figure 1 to illustrate the steps of this method.

[0032] In step S110, a train progress monitoring instruction sent from the monitoring terminal is received, and the train progress monitoring instruction indicates a train that needs to be monitored for operation progress.

[0033]Specifically, the staff at the monitoring end can select the train to be monitored for the operation progress from the operation progress monitoring list, that is to say which train to select will enter the supervision and control of the operation progress. The work progress monitoring list configures the train information of all trains that need to perform pick-up and drop-off operations and in-station operations at the same station within a certain set time period (such as the current ...

Embodiment 2

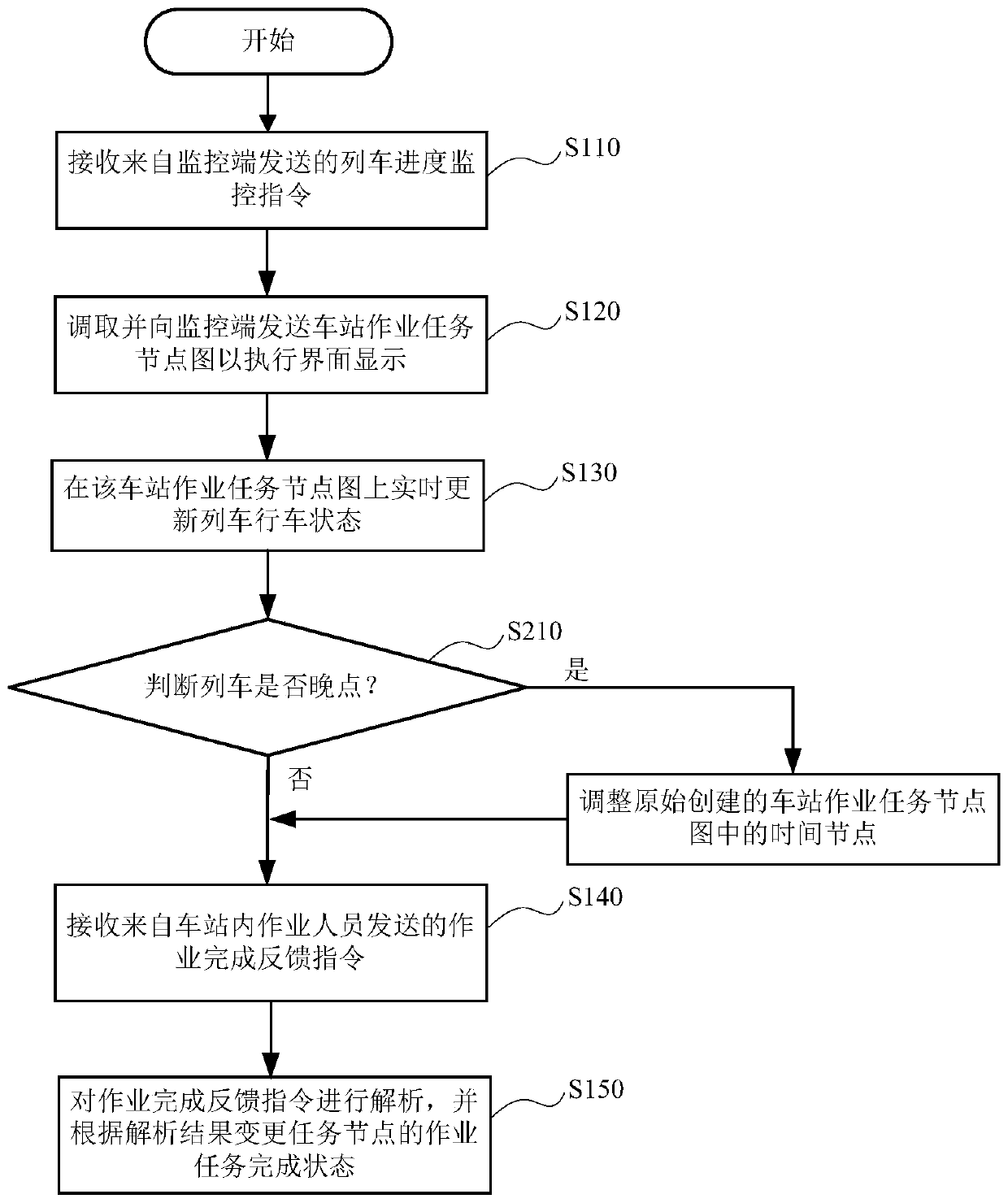

[0055] Due to weather reasons, such as meteorological disasters or geological disasters (line interruptions caused by mudslides, landslides, typhoons, etc. will seriously affect driving), for driving safety, sometimes a temporary speed limit is set so that the train cannot reach the front station on time. There is no way to start on time. Or delays caused by ineffective organization of passenger and freight operations, conflicts in the entry and exit routes of stations, equipment failures, slow speed limits in sections due to construction, and train accidents. In this case, since the existing paper plan has already been formed before the emergency, if it needs to be changed, a lot of manpower will be wasted, and, due to the emergency, it may not be possible to make changes in time. Faced with such a situation, the present embodiment has been proposed.

[0056] figure 2 It is a schematic flowchart of the operation progress monitoring method for monitoring the operation in th...

Embodiment 3

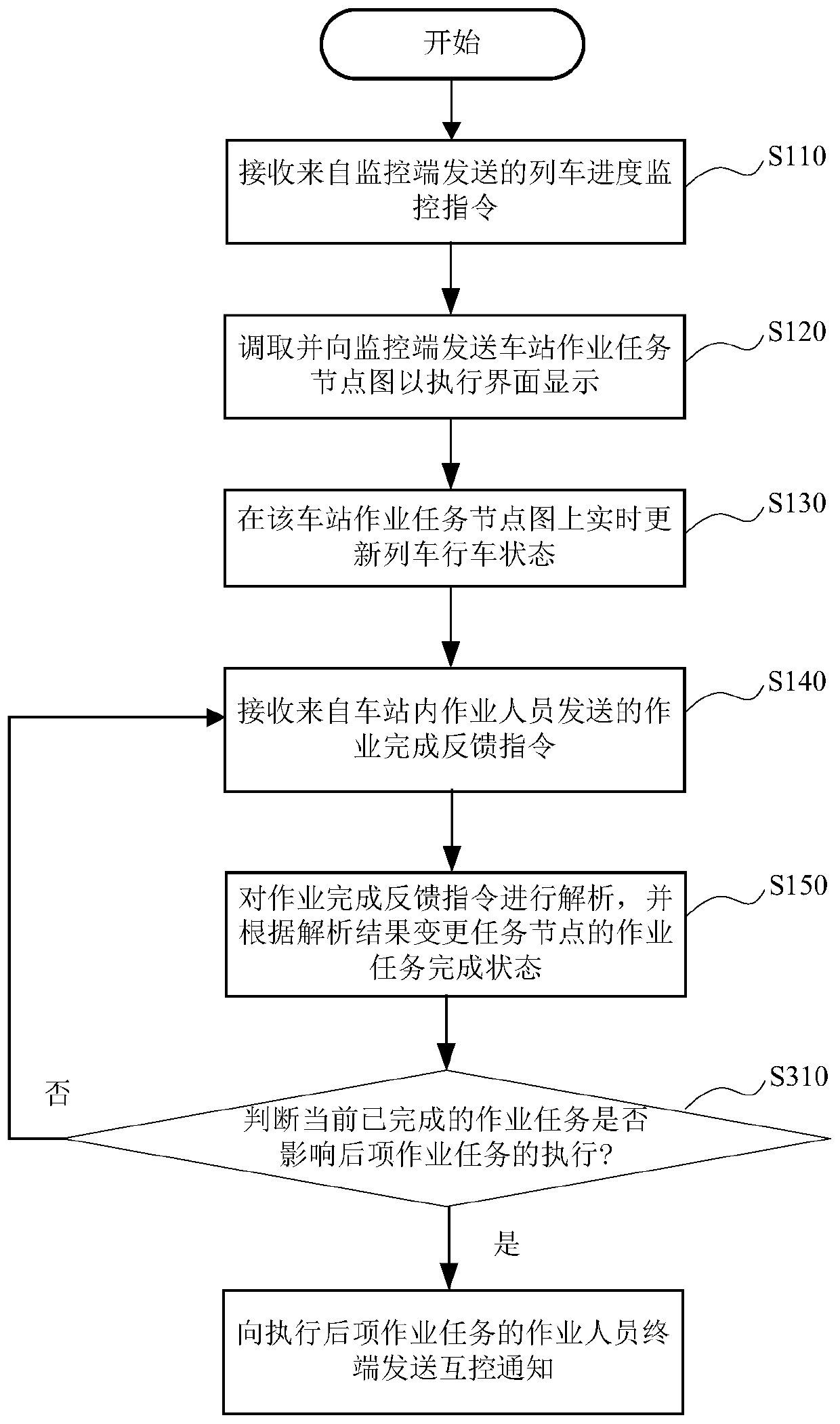

[0066] In the current process of receiving and sending trains, two or more tasks in the station must be executed in a certain order, and there is a constraint relationship between them, that is, when the former task is not completed, the latter task must not be completed. If this principle is violated and the order of completion changes, it will also lead to serious consequences, and it will not be possible to guarantee that the train will leave on time. And because at present all is the in-station operation information of artificial memory train, often can occur because human factor causes in-station operation order error, therefore for existing problem, proposes the embodiment of the present application.

[0067] image 3 It is a schematic flowchart of the operation progress monitoring method for monitoring the operation in the railway station according to the third embodiment of the present application. exist image 3 Steps that are the same as or similar to those in Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com