Automobile front bumper punching and welding integrated device

A bar punching and automobile technology, which is applied in the field of auto parts processing equipment, can solve the problems of troublesome picking and placing, low production efficiency, and inability to carry out mass production, and achieves the effect of saving time, labor and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

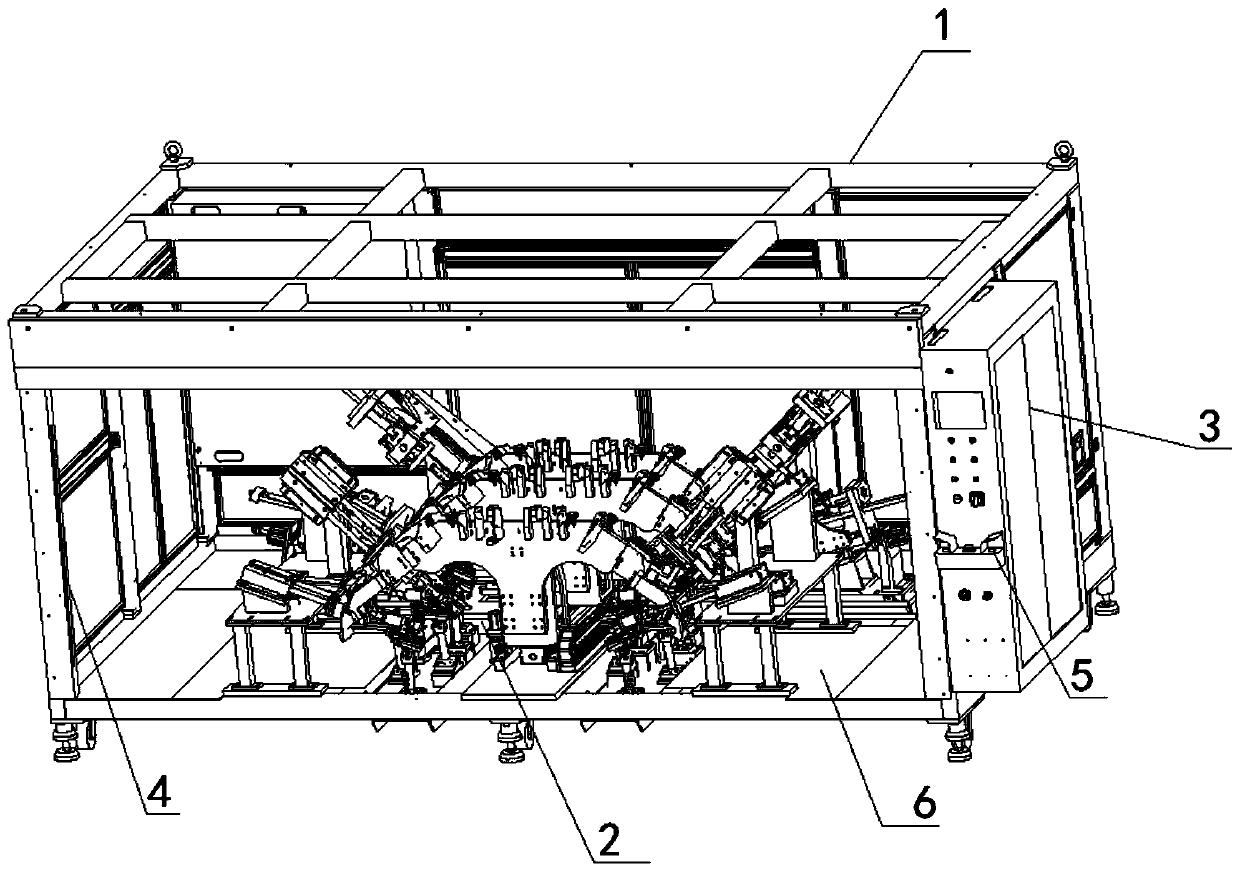

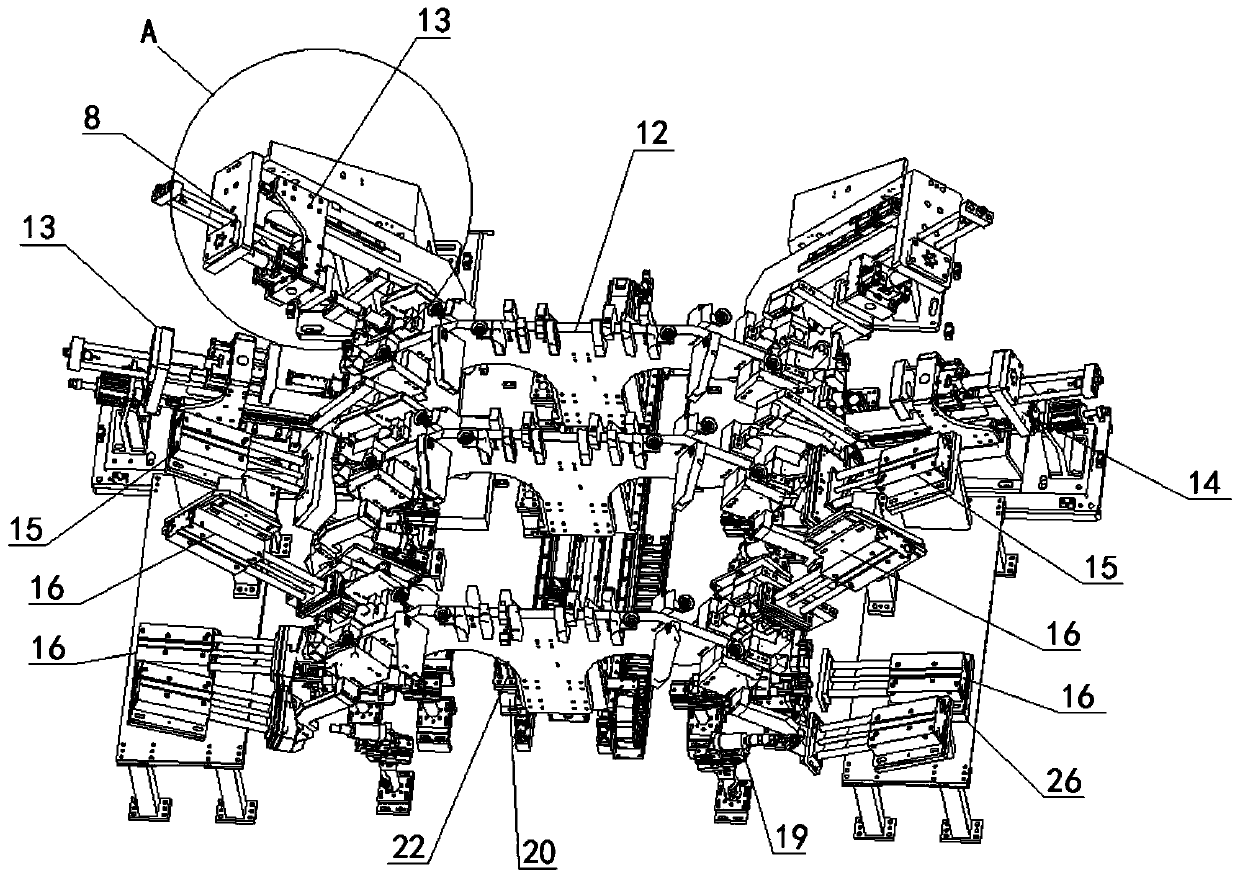

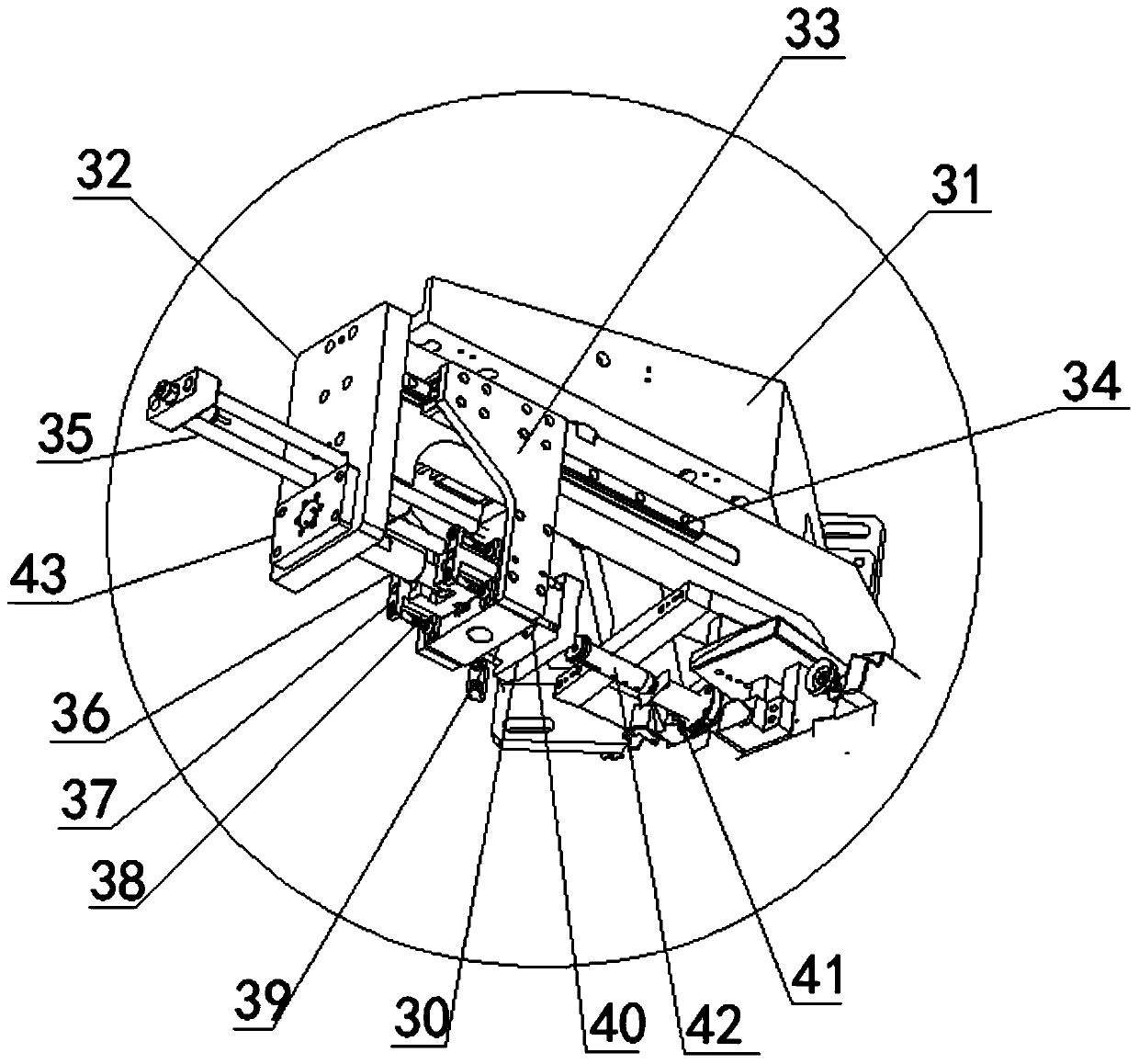

[0019] a kind of like Figure 1-4 The shown automotive front bumper punching and welding integrated equipment includes a frame 1 and a punching and welding mechanism 2, wherein the frame 1 is a frame structure with an open front. The frame 1 has a support plate 6 on which the punching and welding mechanism 2 is installed. The punching and welding mechanism 2 includes a large frame welding station, a small frame welding station, and a punching station arranged in sequence from front to back, and the punching and welding structure is a left-right symmetrical structure. The symmetrical center line of the punching and welding mechanism 2 is provided with a support mold tire 12 that moves horizontally back and forth, and the support mold tire 12 can move to each station. Wherein the punching station includes four air pressure booster cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com