Grass bundling rope bundling and knotting device

A knotting device and straw rope technology, which is applied to the parts of the binding machine, can solve the problems of time-consuming and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

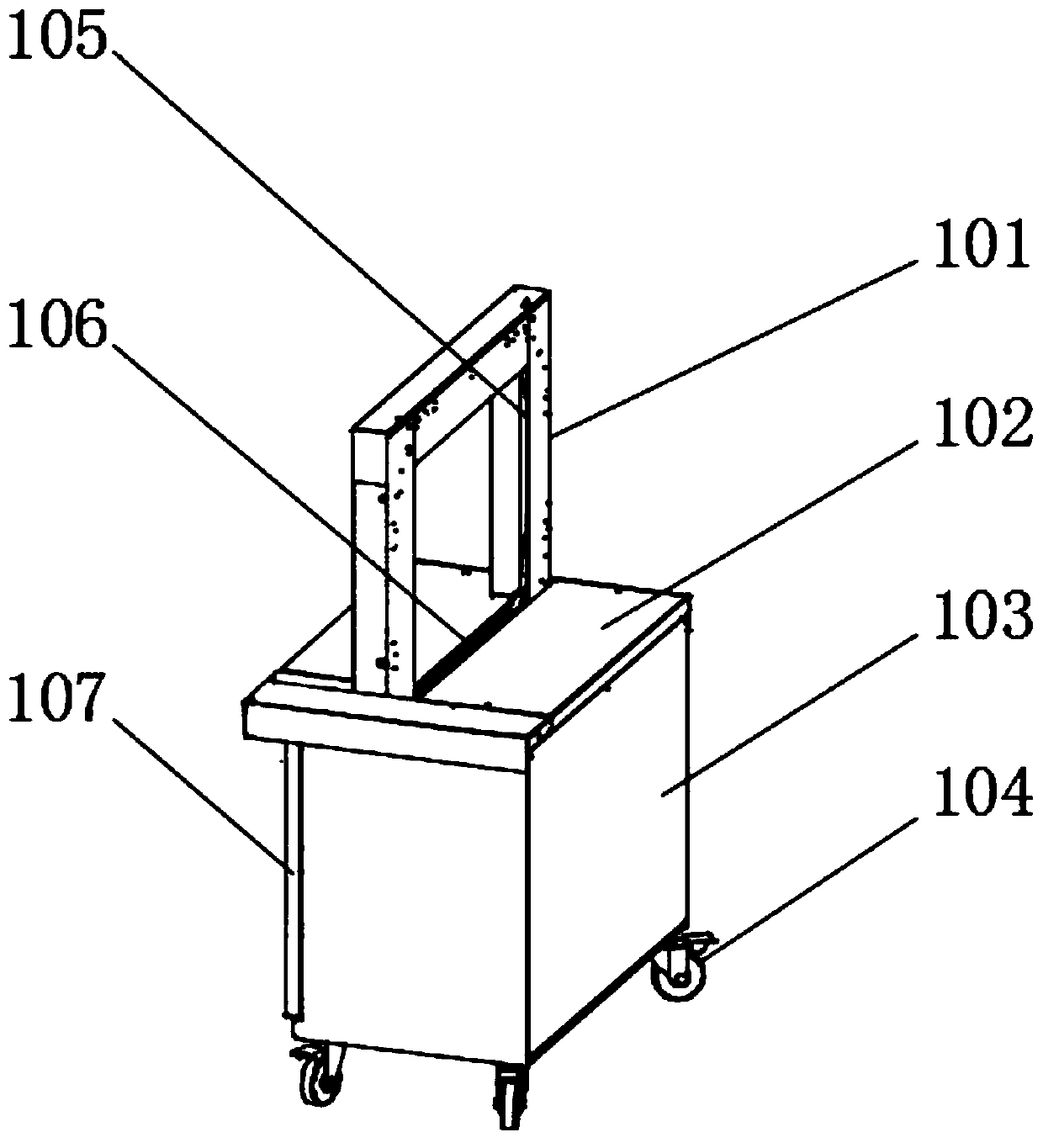

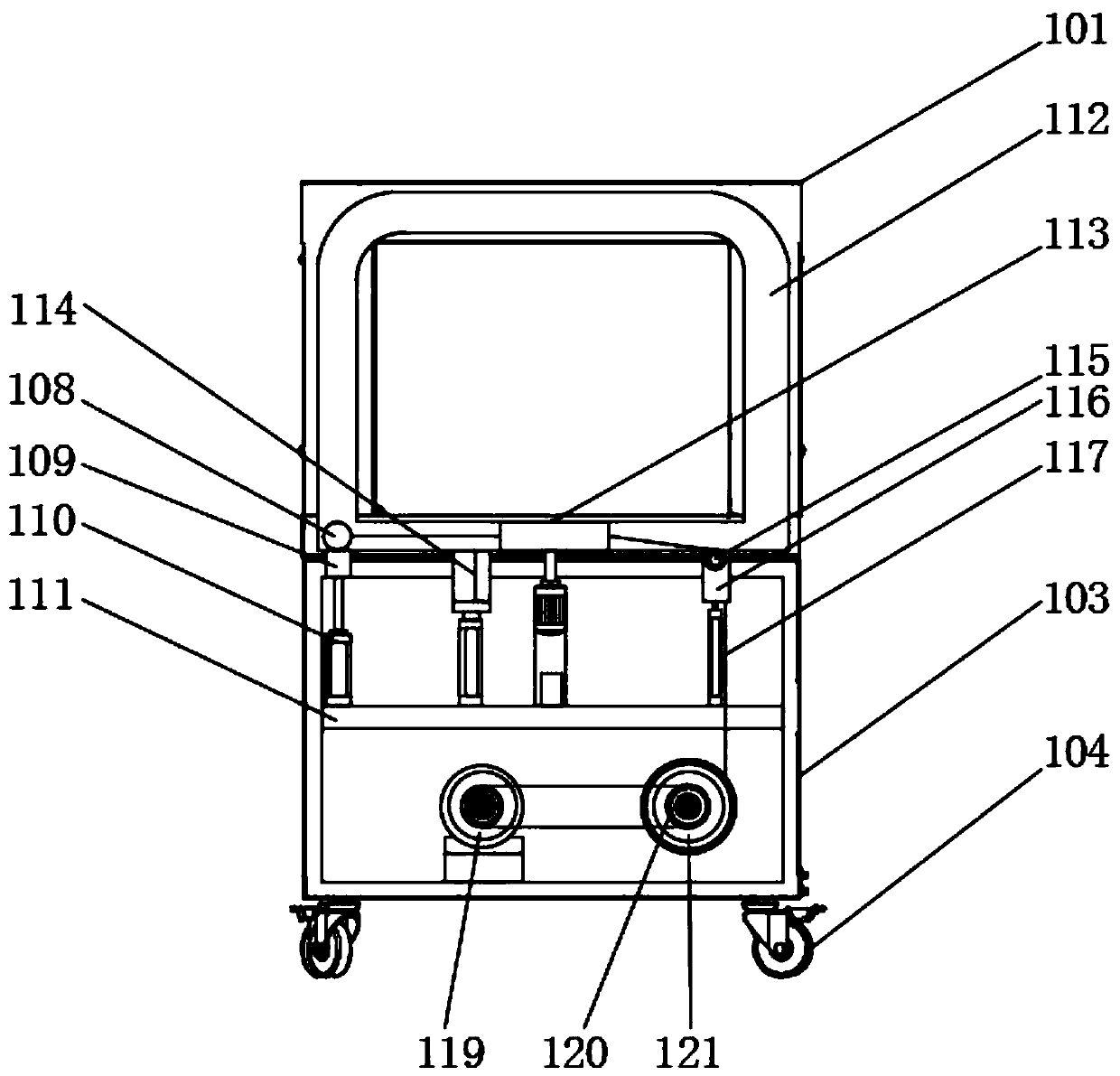

[0035] see Figure 1-10 As shown, the present embodiment is a binding and knotting device for bale ropes, including a mounting frame 101, a binding box 103, an operating console 102 is installed on the top of the binding box 103, and an outlet slot 106 is provided at the central axis of the operating console 102. The binding box 103 is equipped with a mounting frame 101 above the outlet slot 106, and the inside of the mounting frame 101 is provided with a drop slot 105;

[0036] The inside of the installation frame 101 and the top of the inner cavity of the operating table 102 are equipped with a winding channel 112, and the inside of the winding channel 112 is movably equipped with a connecting sphere 108, and a knotting box 113 is installed in the middle of the bottom of the winding channel 112, and a knotting box 113 is installed. A clamping and cutting mechanism 114 is provided at the end away from the connecting sphere 108;

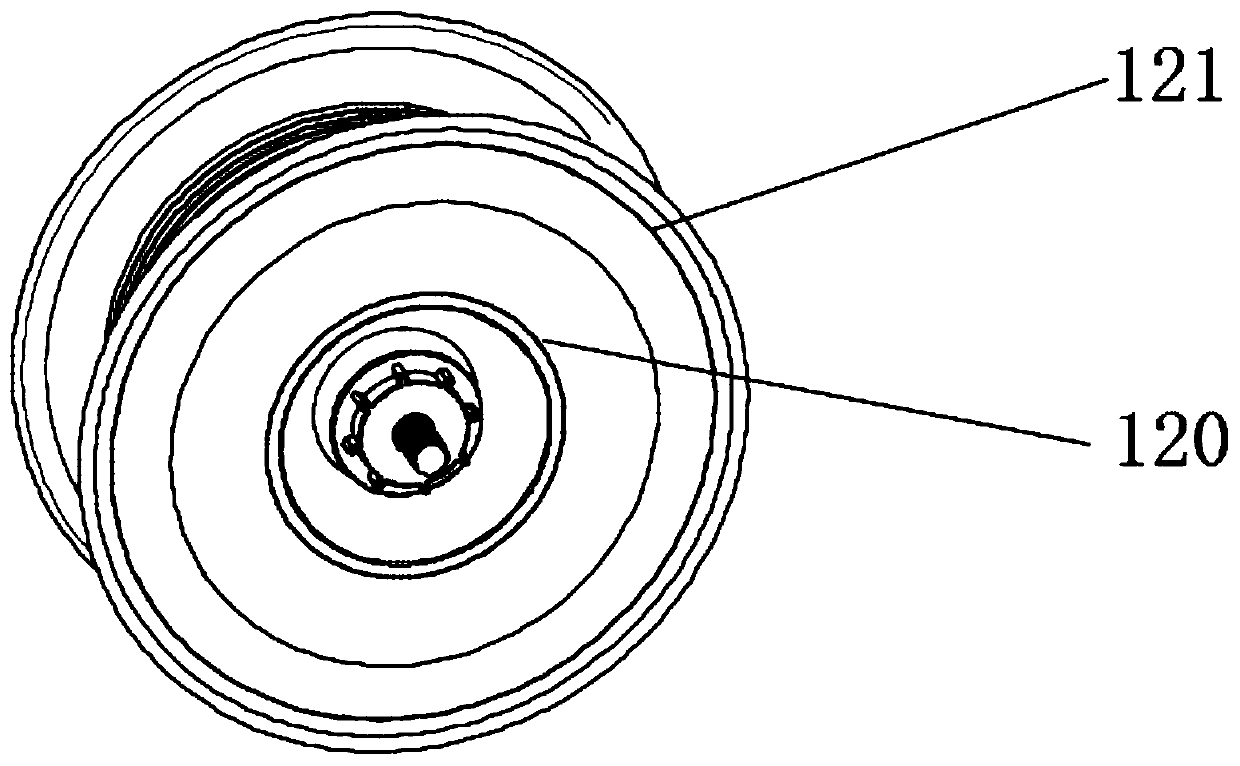

[0037] A first motor 119 is installed at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com