Self-adjusting speed bump with high safety performance

A safety performance, self-adjusting technology, applied to roads, road surface cleaning, road surface lights, etc., can solve the problems of reducing vehicle speed and difficulty in speed bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

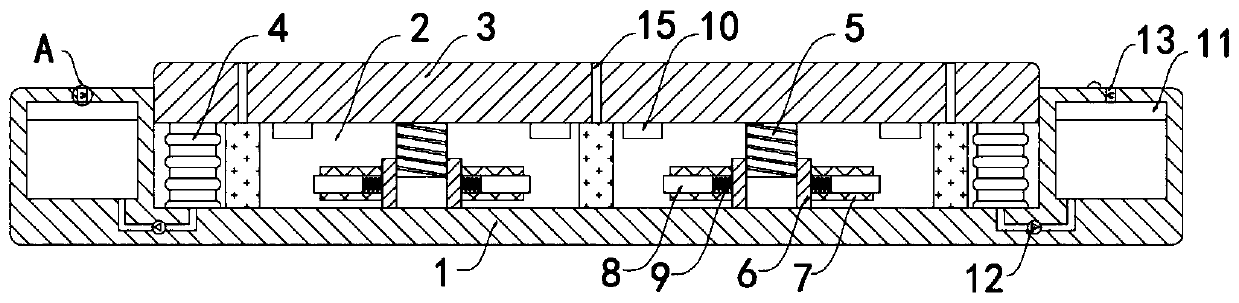

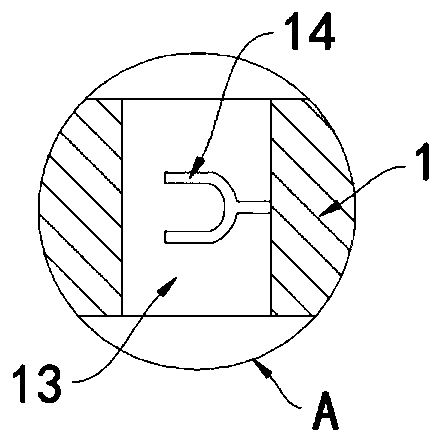

[0021] Such as Figure 1-2 As shown, a self-adjusting deceleration belt with high safety performance includes a base 1, a chute 2 is provided on the upper surface of the base 1, and a deceleration block 3 is slidably connected to the side wall of the chute 2. It should be noted that the deceleration block 3 is provided with a plurality of sound-absorbing holes 15 set through the deceleration block 3. The chute 2 communicates with the outside world through the silencing holes 15. The chute 2 is provided with silencing cotton at the position of the silencing holes 15, and the noise caused by the vehicle passing through the deceleration belt passes through. The sound-absorbing hole 15 enters the chute 2 and is absorbed by the sound-absorbing cotton, which plays a good effect of silencing and noise reduction. The deceleration block 3 is fixedly connected with the bottom surface of the chute 2 through the elastic air bag 4, wherein the elastic air bag 4 is made of rubber material b...

Embodiment 2

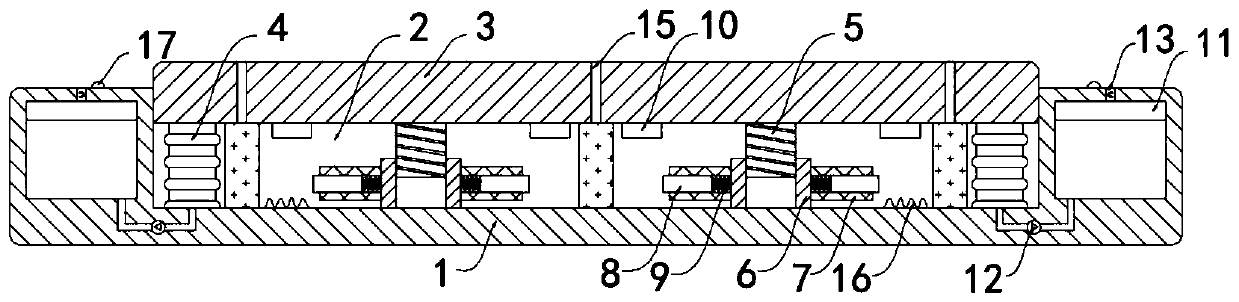

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a closed coil 16 is fixedly installed on the bottom surface of the chute 2, an LED lamp 17 is fixedly installed on the upper end of the base 1 at the water outlet 13, and the LED lamp 17 and the closed coil 16 form a closed loop.

[0030] In this embodiment, when the vehicle passes the deceleration belt, it drives the two permanent magnet blocks 8 to rotate. It can be known from the electromagnetic induction phenomenon that the conductor in the changing magnetic flux will generate an electromotive force, and then an induced current will be generated in the closed coil 16 to make the LED lamp 17 emits light, and the light that LED lamp 17 sends is irradiated on the atomized water, forming comparatively obvious light mist, has played good warning effect, reminds the driver to reduce the speed of a vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com