A vertical inner locking pressure cap

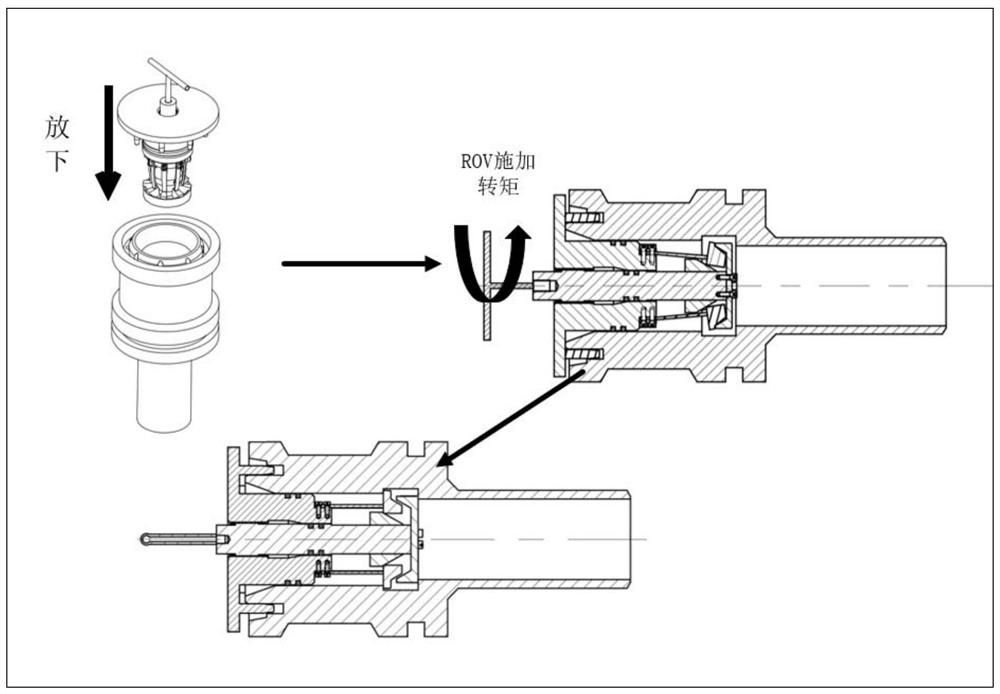

A technology of pressure cap and inner lock, which is applied in wellbore/well components, sealing/package, earthwork drilling and production, etc., which can solve problems such as limited operating space and difficult underwater installation, so as to improve reliability and overcome installation difficulties , The effect of solving the self-locking problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

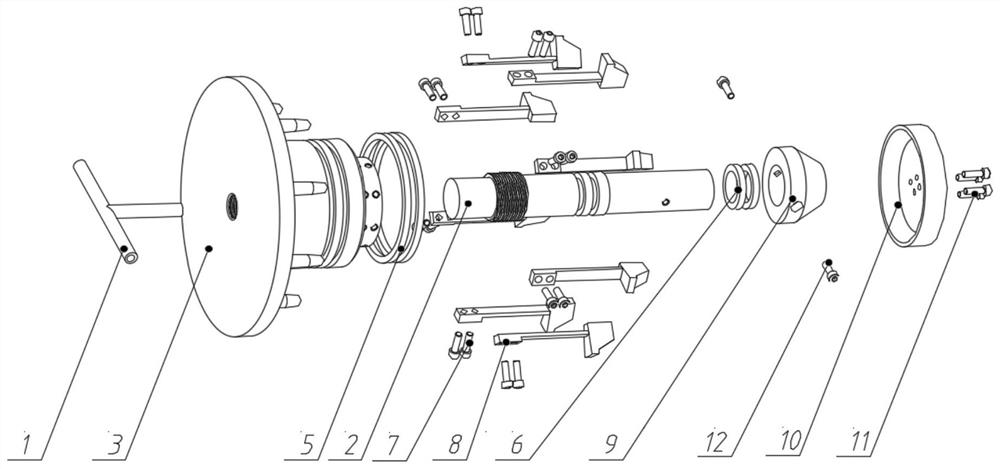

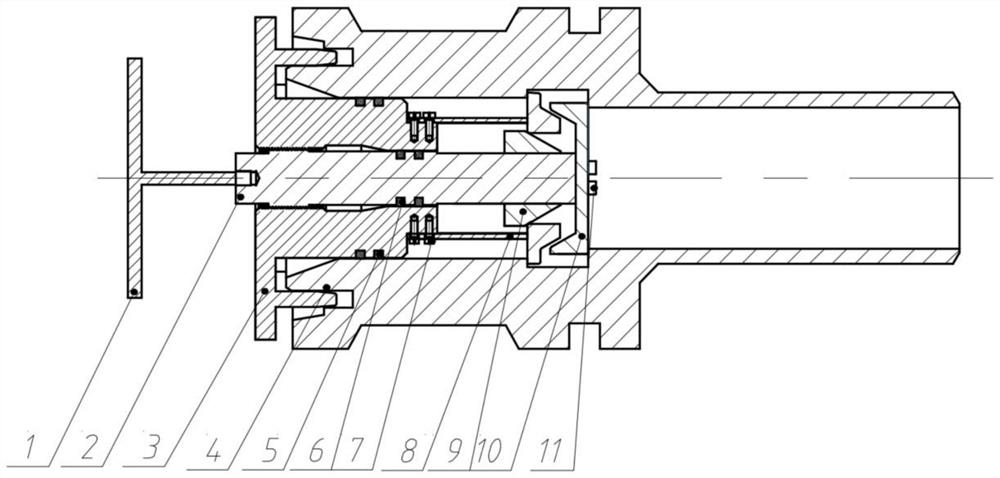

[0022] The vertical inner locking pressure cap of the present invention includes a T-shaped handle, a locking bolt, an outer cylinder nut, a push block, a baffle plate, four sealing rings, and eight clamping blocks. It is characterized in that: The thread of the locking bolt and the outer cylinder nut is a trapezoidal thread, which constitutes a screw mechanism. The screw mechanism converts the rotary motion into a linear motion, thereby driving the movement of the entire pressure cap. The pressure cap is the locking bolt, the outer cylinder nut, the push block, The structure of the baffle and the card block combination.

[0023] The flange protected by the pressure cap is provided with a flared groove and a flared middle hole, and eight inner holes are arranged in the groove. With the aid of the flared structure, the pressure cap and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com