A pipeline intersecting line welding system

A welding system and intersecting line technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as self-locking and redundant constraints, achieve strong operability, reduce equipment investment, The effect of increasing the workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

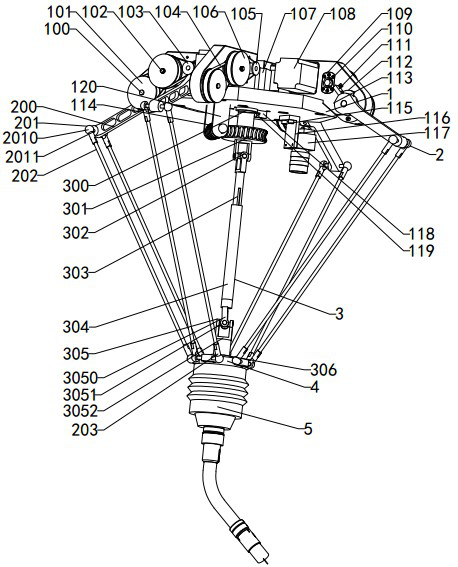

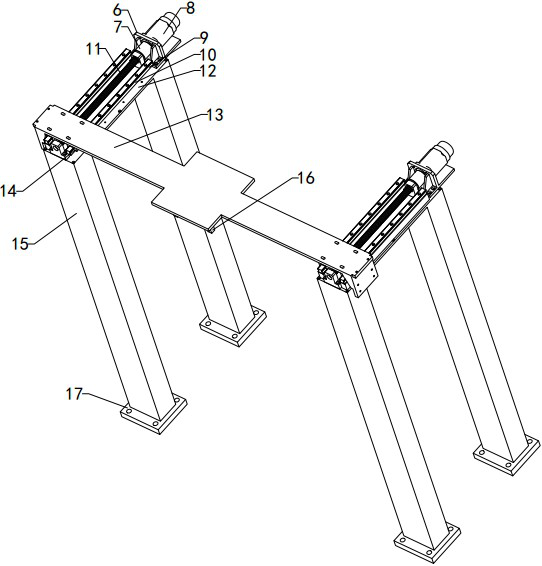

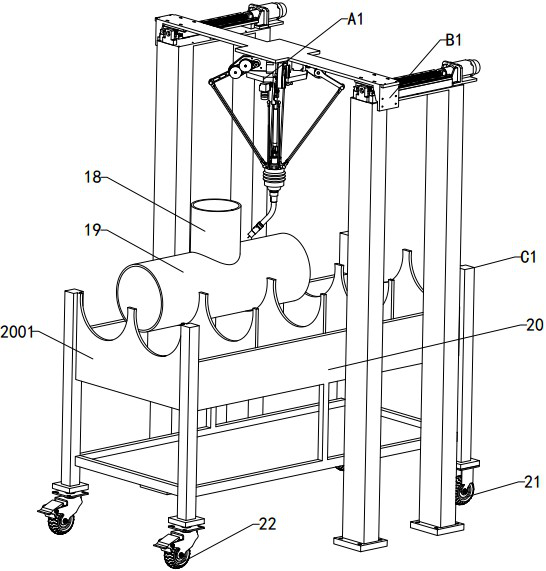

[0026] Figures 1~3 is the best embodiment of the present invention, the following is combined with the appendix Figures 1~3 The present invention will be further described.

[0027] Refer to the attached Figures 1~3 : A pipeline intersecting line welding system, including a parallel robot A1, an electric slide rail assembly B1 and a gantry bracket. The upper part of the portal bracket is provided with an electric slide rail assembly B1, and the upper part of the parallel robot A1 is installed on the electric slide rail assembly B1. On the portal bracket, the lower output end of the parallel robot A1 is equipped with a welding torch 5; the parallel robot A1 includes a fixed platform 1, a moving branch chain 2, a central telescopic branch 3 and a moving table 4, and the fixed platform 1 and the moving table 4 are arranged in parallel up and down , between the fixed platform 1 and the moving table 4 are provided with multiple sets of moving branch chains 2 and a group of cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com