Seat and automobile with same

A technology for seats and automobiles, which is applied in the direction of movable seats, vehicle seats, detachable/non-detachable seats, etc. It can solve the problems of large installation space, complex support device structure, large input power, etc., and achieve power and size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

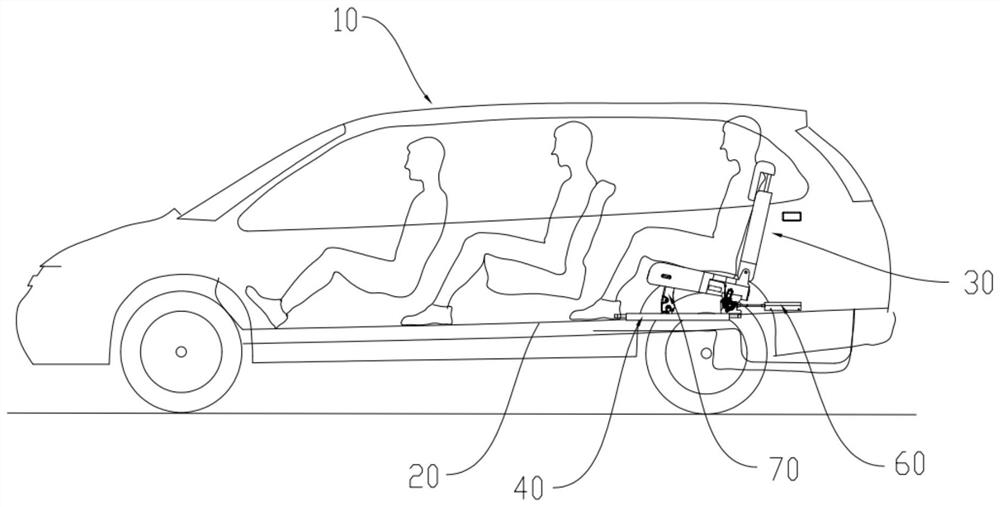

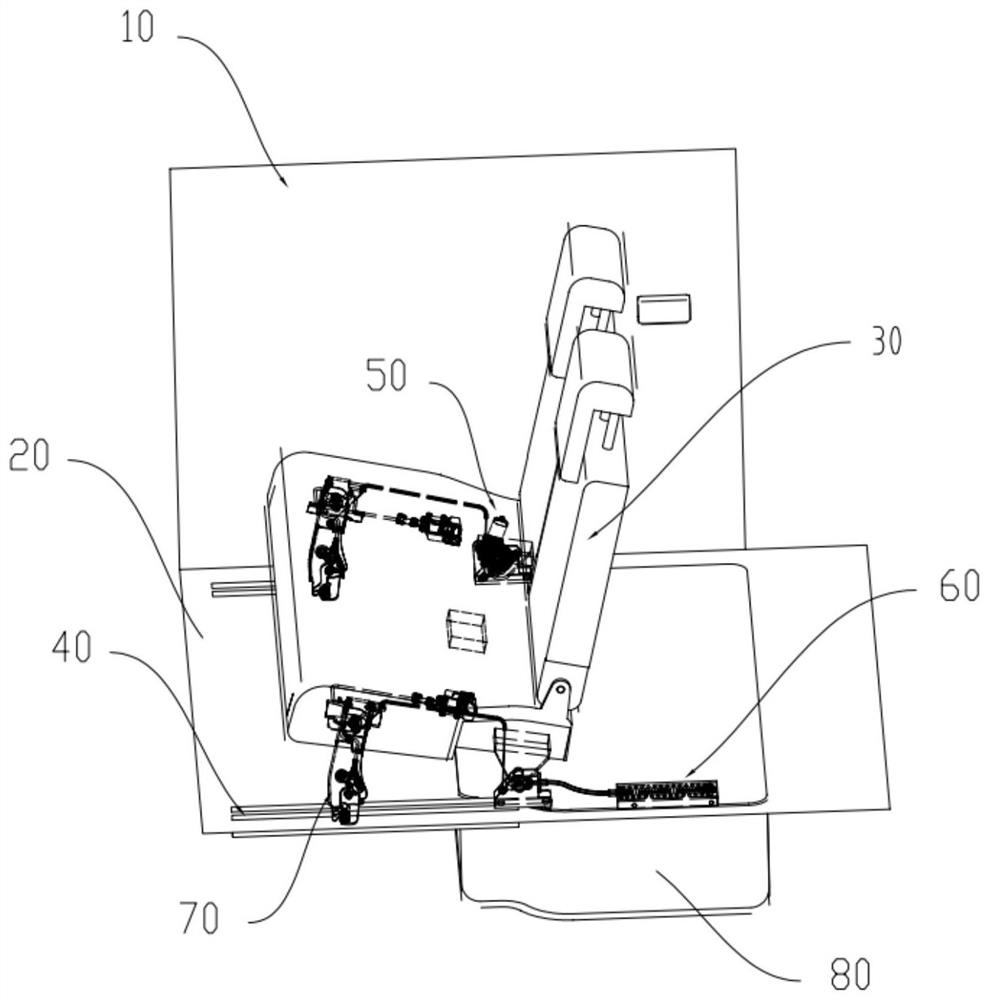

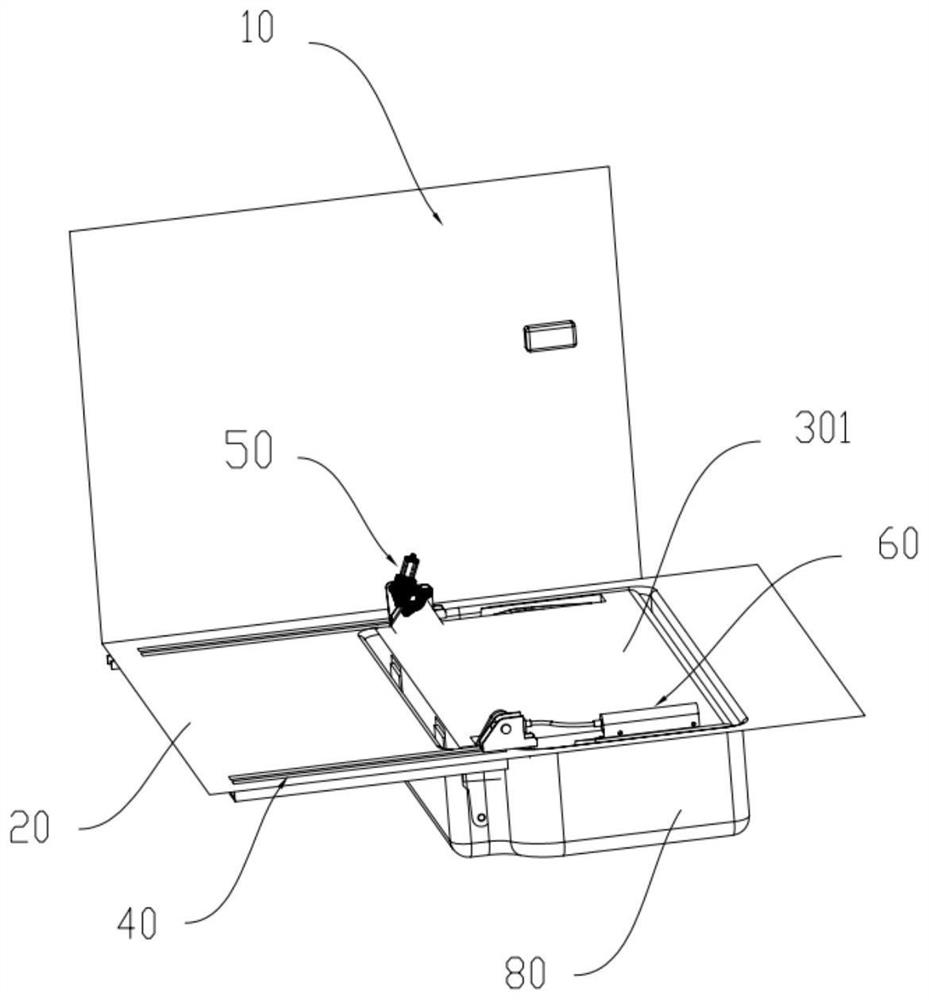

[0088] see figure 2 and Figure 5 , the preferred embodiment of the present invention provides a seat, which is used to be installed on the bottom plate 20 of the automobile 10 to provide a riding function, including a seat body 30, a sliding mechanism 40, an electric drive mechanism 50, an auxiliary device 60 and two The support member 70, the seat body 30 includes a seat cushion 301 and a backrest 302 hinged with the seat cushion 301; the sliding mechanism 40 includes two oppositely arranged sliding rails 401 and a clamping column 402 slidably arranged on the sliding rail 401; the electric drive mechanism 50 is provided with On one of the sliding rails 401, the electric drive mechanism 50 is hinged with the rear end of the seat cushion 301 to drive the seat cushion 301 to turn over; the auxiliary device 60 is arranged on the other sliding rail 401, and the auxiliary device 60 is hinged with the rear end of the seat cushion 301 to It is used to assist the electric drive mec...

Embodiment 2

[0094] see Image 6 , the preferred embodiment of the present invention provides an auxiliary device 60, which is used to rotatably connect the seat and the bottom plate 20, including an actuator 601, a first transmission cable 603 and a power mechanism 602; the actuator 601 includes a first support A frame 6011, a connecting shaft 6012 and a crank 6013, the first support frame 6011 is arranged on the bottom plate 20; one end of the connecting shaft 6012 is rotatably installed on the first support frame 6011, the other end is connected to the seat, and the connecting shaft 6012 rotates with the seat The crank 6013 is sleeved with the connecting shaft 6012, and the crank 6013 rotates with the connecting shaft 6012; one end of the first transmission cable 603 is connected to the crank 6013, and the other end is connected to the power mechanism 602; The first torque, and the power mechanism 602 pulls the first transmission cable 603, so that the crank 6013 receives a second torqu...

Embodiment 3

[0113] see Figure 8 Compared with the embodiment, this embodiment adopts a different power mechanism 602. The power mechanism 602 of this embodiment includes a casing 6021, a first support shaft 6024, a first torsion spring 6025 and a support ring 6026, and the first support shaft 6024 is provided with The support ring 6026 is arranged on the housing 6021, and the support ring 6026 is coaxial with the first support shaft 6024, and the support ring 6026 is provided with a lap groove 60261; the first torsion spring 6025 has a first support arm 60251 and The second support arm 60252, the first torsion spring 6025 are sleeved on the first support shaft 6024, and the first support arm 60251 is inserted into the lap groove 60261; the second support arm 60252 is connected with the other end of the first transmission cable 603 .

[0114] Specifically, the first support arm 60251 is locked in the lap groove 60261 and cannot move, so that the first torsion spring 6025 cannot rotate; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com