Automatic fiberboard composite board laying device

An automatic laying and composite board technology, applied in road repair, roads, roads, etc., can solve problems such as easy neglect, high physical consumption, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

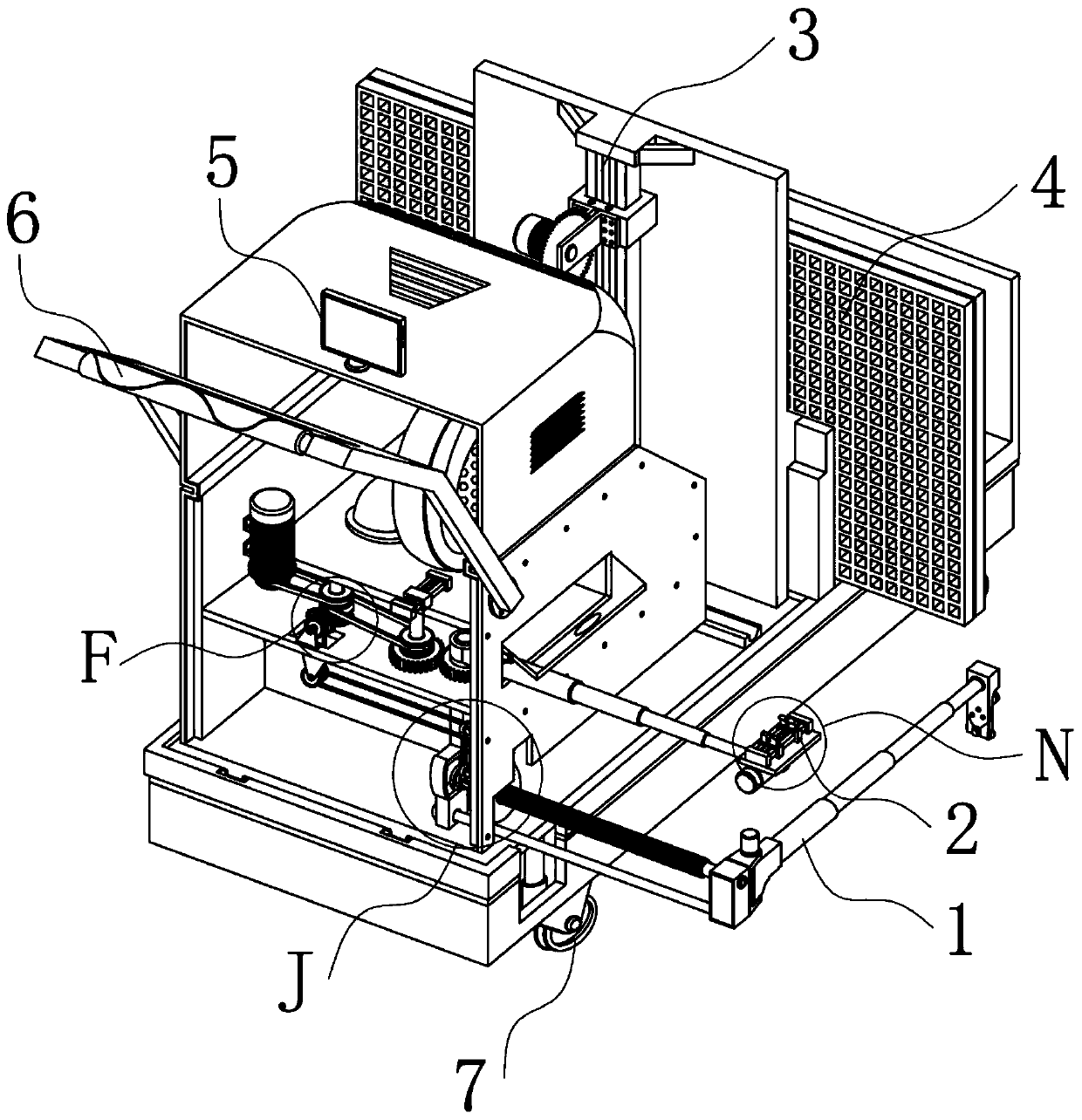

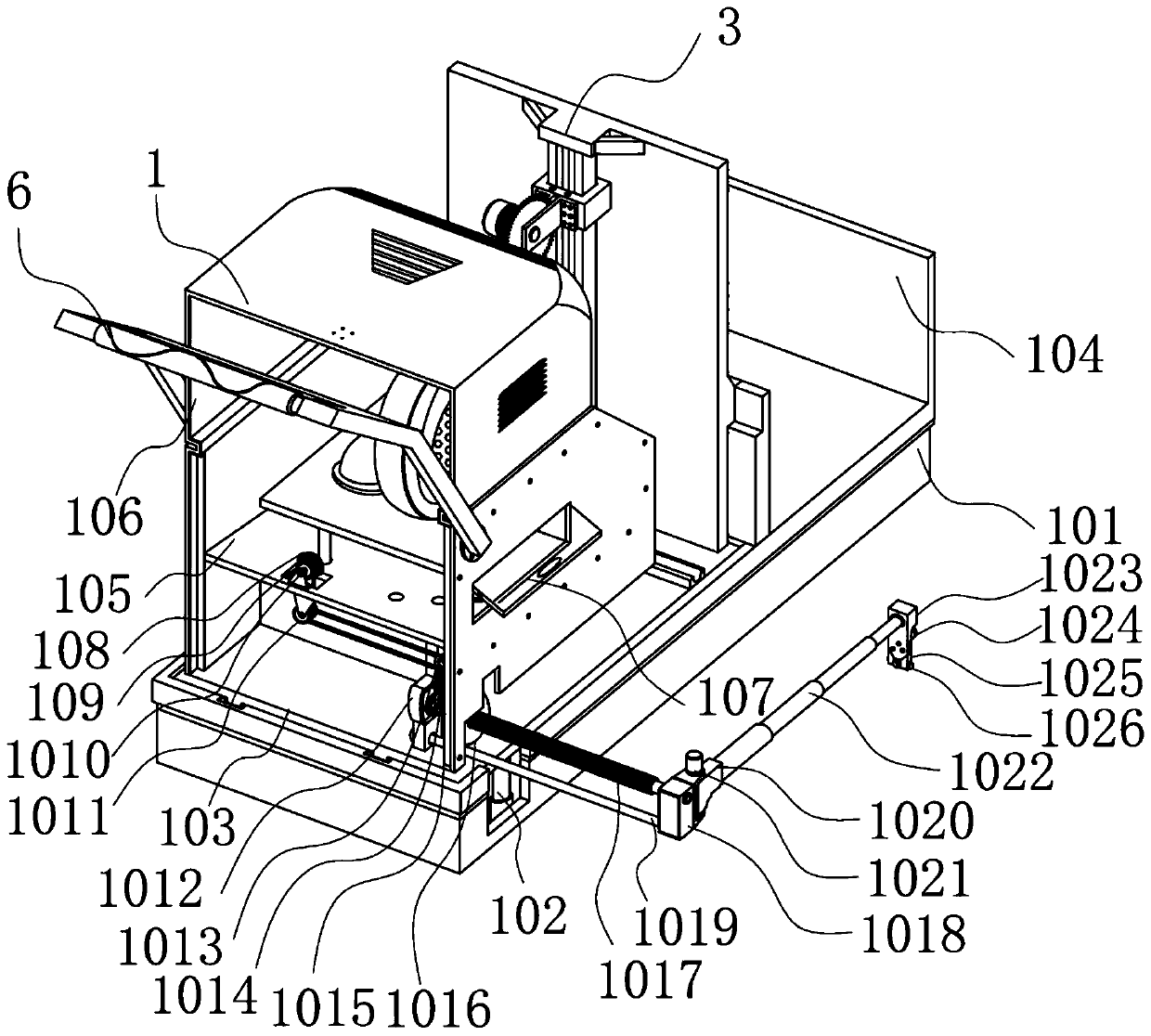

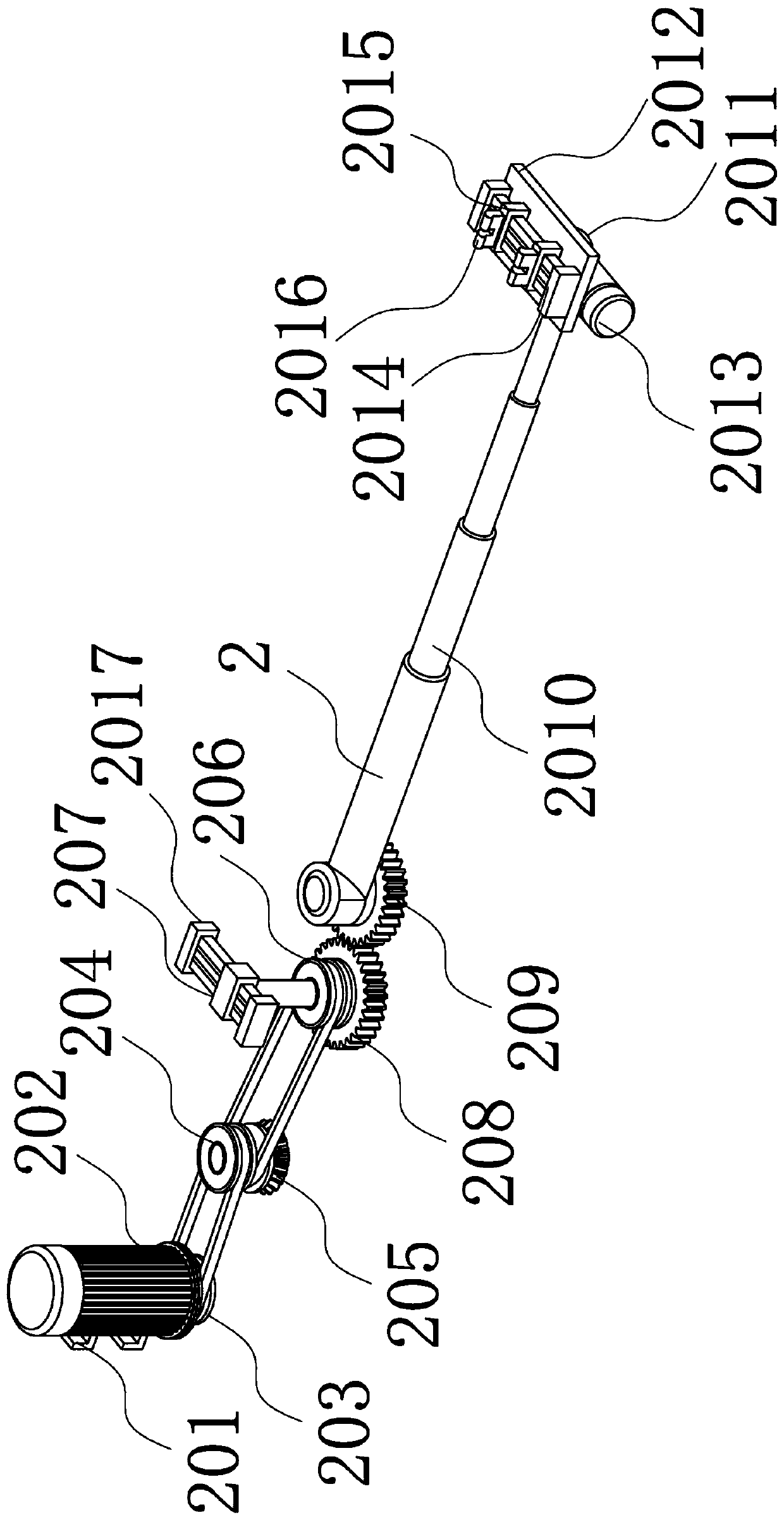

[0033] A fiberboard composite board automatic laying device, such as Figure 1-10 As shown, it includes automatic measuring mechanism 1, automatic laying mechanism 2, cutting mechanism 3, FRP grating 4, control panel 5, push rod frame 6 and universal wheel 7; the middle and front part of automatic measuring mechanism 1 is equipped with automatic laying mechanism 2. A cutting mechanism 3 is installed in the middle of the automatic measuring mechanism 1; a glass steel grating 4 is placed on the top and rear side of the automatic measuring mechanism 1; a control panel 5 is installed in the middle and front of the top of the automatic measuring mechanism 1; the outer front and middle of the automatic measuring mechanism 1 is installed There is a push rod frame 6; the right front part of the bottom end of the automatic measuring mechanism 1 is provided with a universal wheel 7.

[0034] Described, automatic measuring mechanism 1 comprises car body underframe 101, first electric pus...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap