Garbage can capable of automatically dumping decoration waste

A technology of garbage bins and dumping devices, which is applied in the direction of garbage bins, garbage collection, garbage cleaning, etc., and can solve the problems of reducing the use range of garbage bins, not being able to adjust the garbage bin, and not being able to adjust the height of the garbage bin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

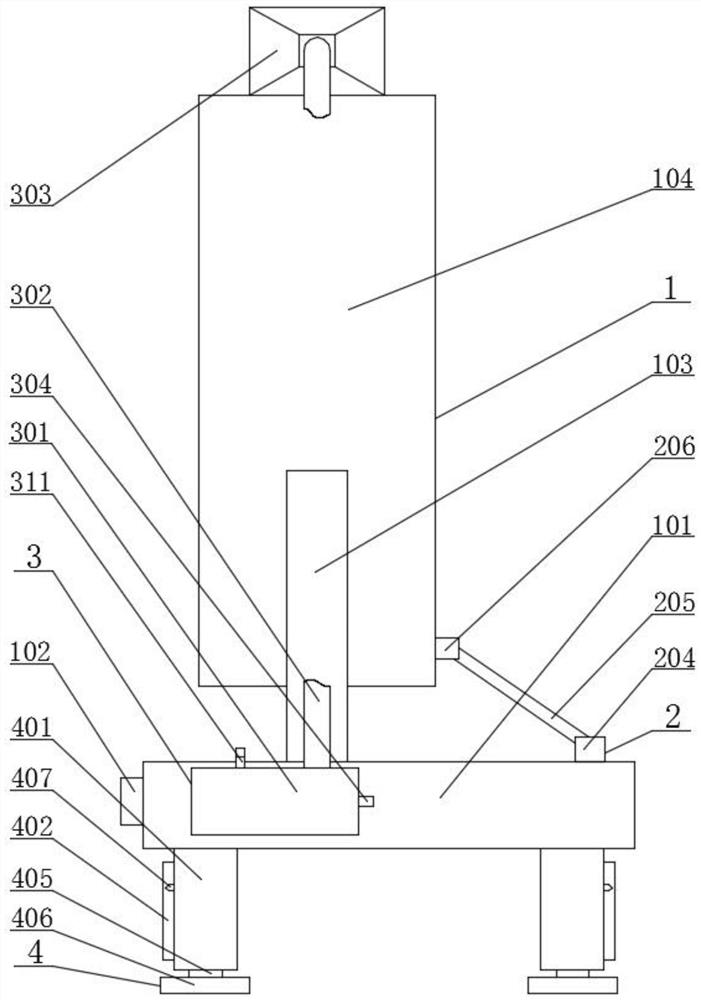

[0026] see Figure 1-7 , the present invention provides a technical solution:

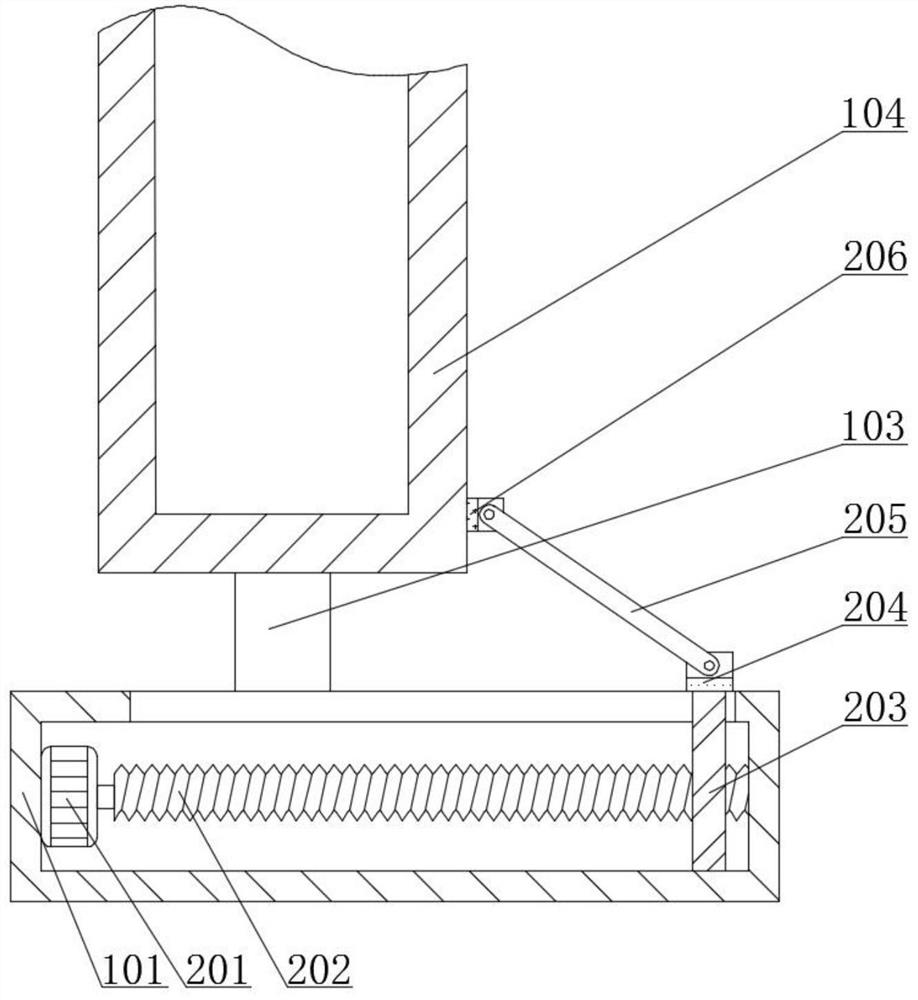

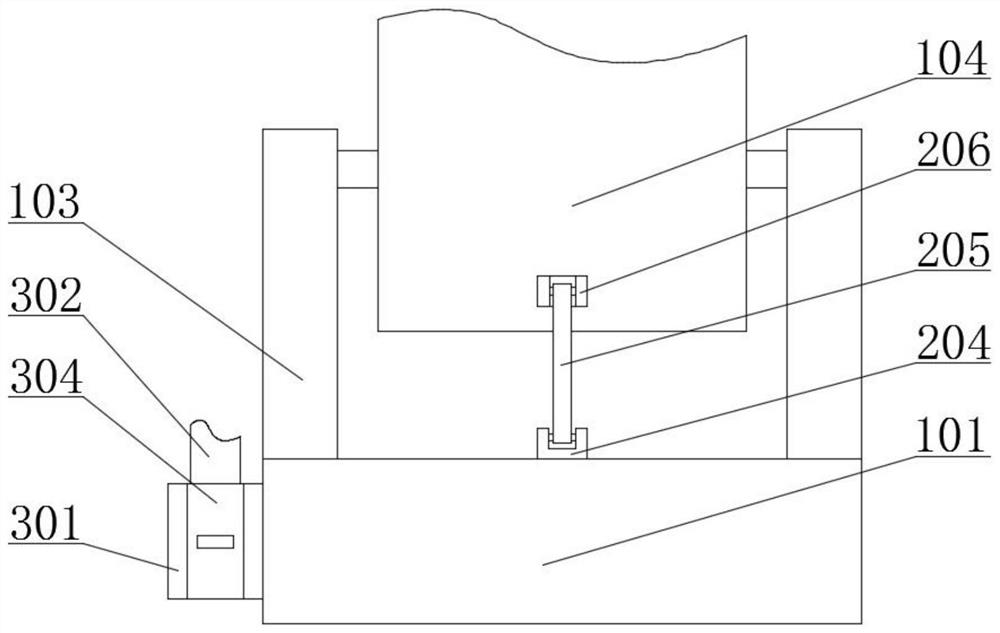

[0027] A dustbin capable of automatically dumping decoration waste, comprising a main device 1, an automatic dumping device 2, a dust collector 3 and an adjusting device 4, the main device 1 includes a base 101 and a dustbin 104, the left end of the base 101 is fixedly connected with a controller 102, the left side of the top surface of the base 101 is fixedly connected with the connecting plate 103, the garbage bin 104 is connected with the connecting plate 103 in rotation, the automatic dumping device 2 includes a first motor 201 and a rotating rod 205, the first motor 201 is fixedly connected with the base 101, the second The end of the main shaft of a motor 201 is fixedly connected with a first threaded shaft 202, the first threaded shaft 202 is rotationally connected with the base 101, the outer side of the first threaded shaft 202 is spirally connected with a slider 203, the slider 203 runs t...

Embodiment 2

[0031] In embodiment 2, the same part as in embodiment 1 will not be described in detail, please refer to the different parts Figure 1-8 , the present invention provides a technical solution:

[0032] The adjustment device 4 includes a first leg 401 and a scale 402, the first leg 401 is fixedly connected to the base 101, the scale 402 is fixedly connected to the first leg 401, and the inner side of the top end of the first leg 401 is sleeved with a second The motor 403, the main shaft end of the second motor 403 is fixedly connected with the second threaded shaft 404, the second threaded shaft 404 is spirally connected with the second leg 405, the second leg 405 is slidingly connected with the first leg 401, the second The bottom surface of the leg 405 is fixedly connected with a bottom plate 406, which can adjust the height of the dustbin 104 and expand the use range of the dustbin 104; the outer top of the second leg 405 is fixedly connected with a pointer 407, and the poin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap