T-shaped sliding rail

A technology of slide rails and sliders, which is applied to T-shaped slide rails. It can solve the problems of unable to control the moving speed of the slider on the slide rail, unable to stop, lack of limit device, etc., to achieve the effect of enhancing practicability, optimizing use and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

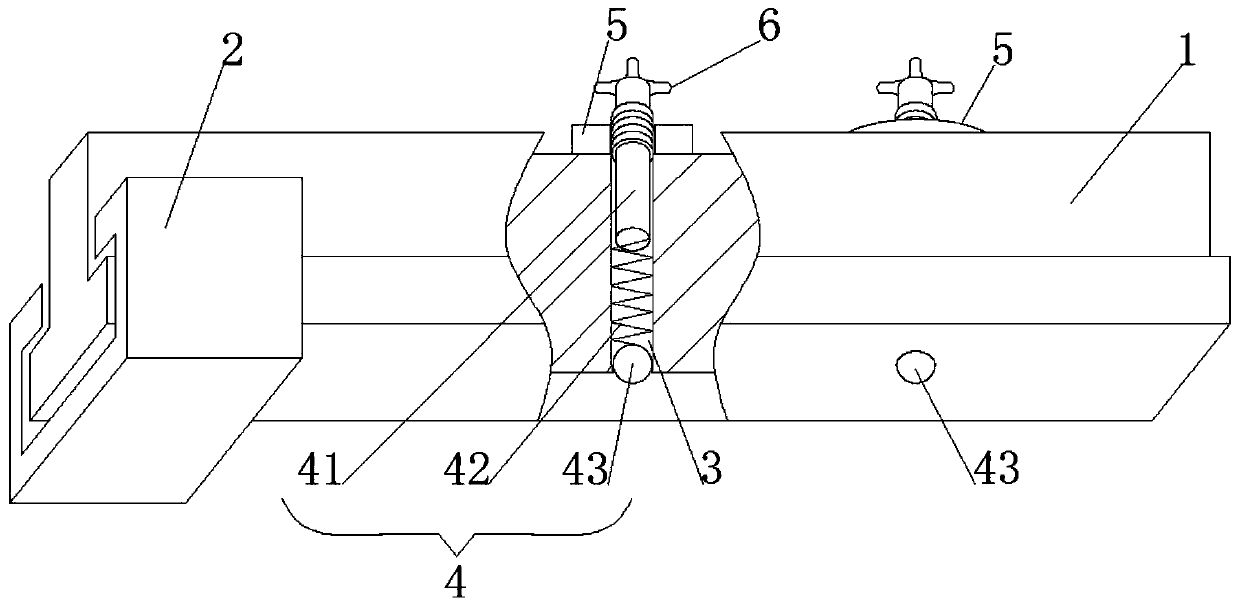

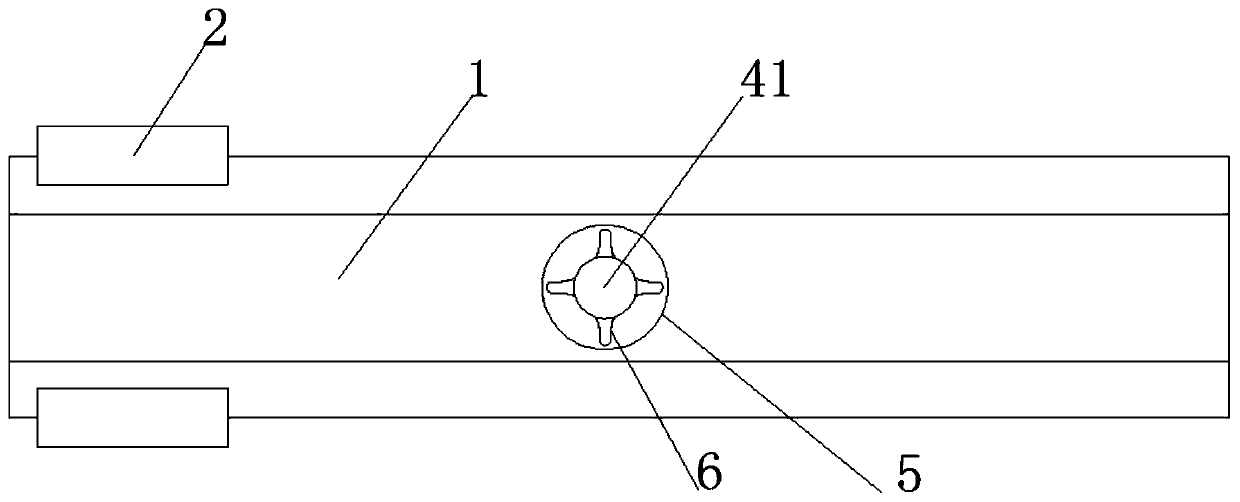

[0018] See Figure 1-2 This embodiment provides a T-shaped slide rail, including a slide rail 1, a sliding block 2 is slidably connected below the slide rail 1, a through hole 3 is opened inside the slide rail 1, and an internal elastic connection limit device for the through hole 3 4.

[0019] In this design, the slider 2 slides under the slide rail 1. By adjusting the limit device 4, the sliding speed of the slider 2 can be controlled, and by adjusting the limit device 4, the slider 2 can also be suspended from sliding.

Embodiment 2

[0021] See Figure 1-2 , A further improvement is made on the basis of embodiment 1: the limit device 4 includes a limit rod 41, a spring 42 and a metal ball 43, the metal ball 43 is fixedly connected to the bottom of the spring 42, and the spring 42 is fixedly connected to the limit rod 41 bottom of.

[0022] Among them, the spring 42 is in a compressed state, and the spring 42 presses the metal ball 43 downward so that the lower end of the metal ball 43 protrudes from the opening at the lower end of the through hole 3. When the compression degree of the spring 42 is small, the slider 2 passes the position of the metal ball 43 and the inner wall of the slider 2 Squeeze the metal ball 43 upward and decelerate to achieve the deceleration effect of the slider 2. By adjusting the limit lever 41 downward, the force of the limit lever 41 pressing the spring 42 downward increases, which increases the force on the metal ball 43. When the slider 2 passes through the metal ball 43, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com