A method and device for generating batch cutting and placement graphics

A graphics generation and batch technology, applied in metal processing and other directions, can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

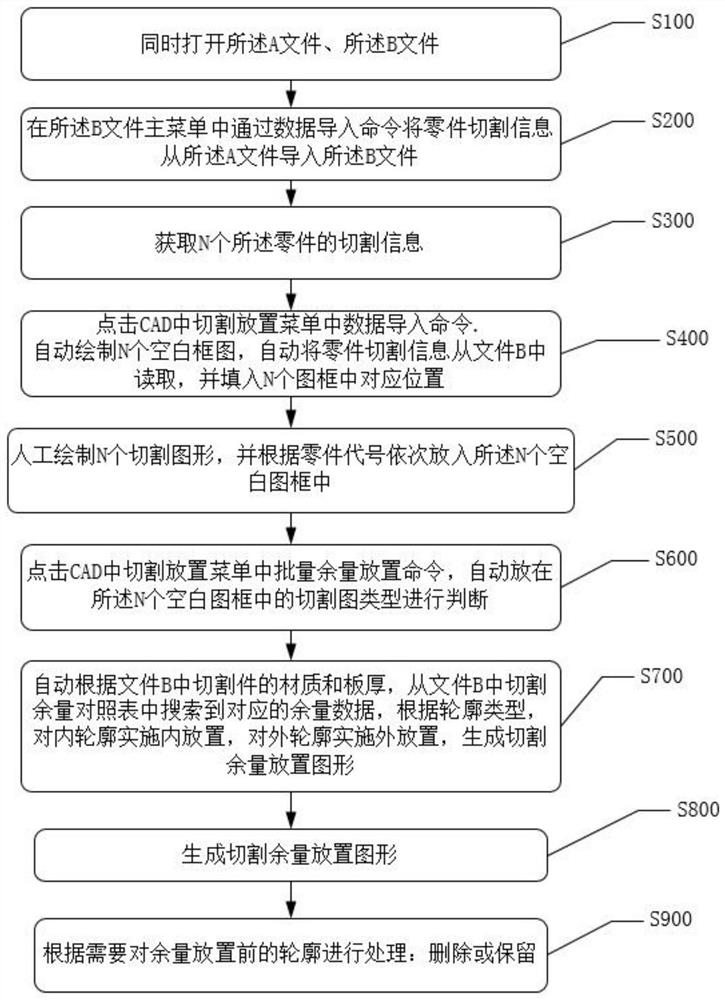

[0035] A batch cutting and placement graphics generation method for batch processing of cutting images, including a cutting diagram C file containing N parts to be cut and placed, an A file, and a B file, wherein the C file refers to a CAD file , the A file refers to the Excel process flow card, and the B file refers to the Excel cutting list. Such as figure 1 Shown is the main menu interface of the B file, such as figure 2 Shown is the menu interface of the C file.

[0036] First of all, the information of the N parts to be cut in the "Cutting Parts List" can be manually input by the staff, but it is cumbersome, but the company's parts information is stored in an Excel table, such as Figure 8 As shown, this embodiment named it "process flow card", therefore, this embodiment additionally provides a method for automatically inputting cutting information, the "process flow card" includes at least the codes and names of N parts , material, plate thickness, length and width, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com