Device with stone brick flatness detecting and repairing functions

A technology of flatness detection and function, which is applied in the field of stone brick processing, and can solve problems such as unfavorable placement levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Stone brick is a high-end interior building decoration material made of natural stone and ceramic board; stone brick has the advantages of natural marble, luxurious atmosphere, natural and smart texture, natural texture, and avoids some defects of marble full-body version. In terms of color, stone bricks are more uniform, waterproof and stain resistant, stronger, lighter, easier to install, and can effectively avoid the shortcomings of alkali return, pollution, cracking, etc.;

[0032] Flatness refers to the deviation of the height of the macroscopic unevenness of the substrate from the ideal plane. Flatness measurement refers to the amount of change between the measured actual surface and its ideal plane. The flatness error is to compare the measured actual surface with the ideal plane, the line value distance between the two is the flatness error value; or by measuring the relative height difference of several points on the actual surface, and then converting to the line...

Embodiment 2

[0046] The embodiment of the present invention is further defined on the basis of embodiment 1.

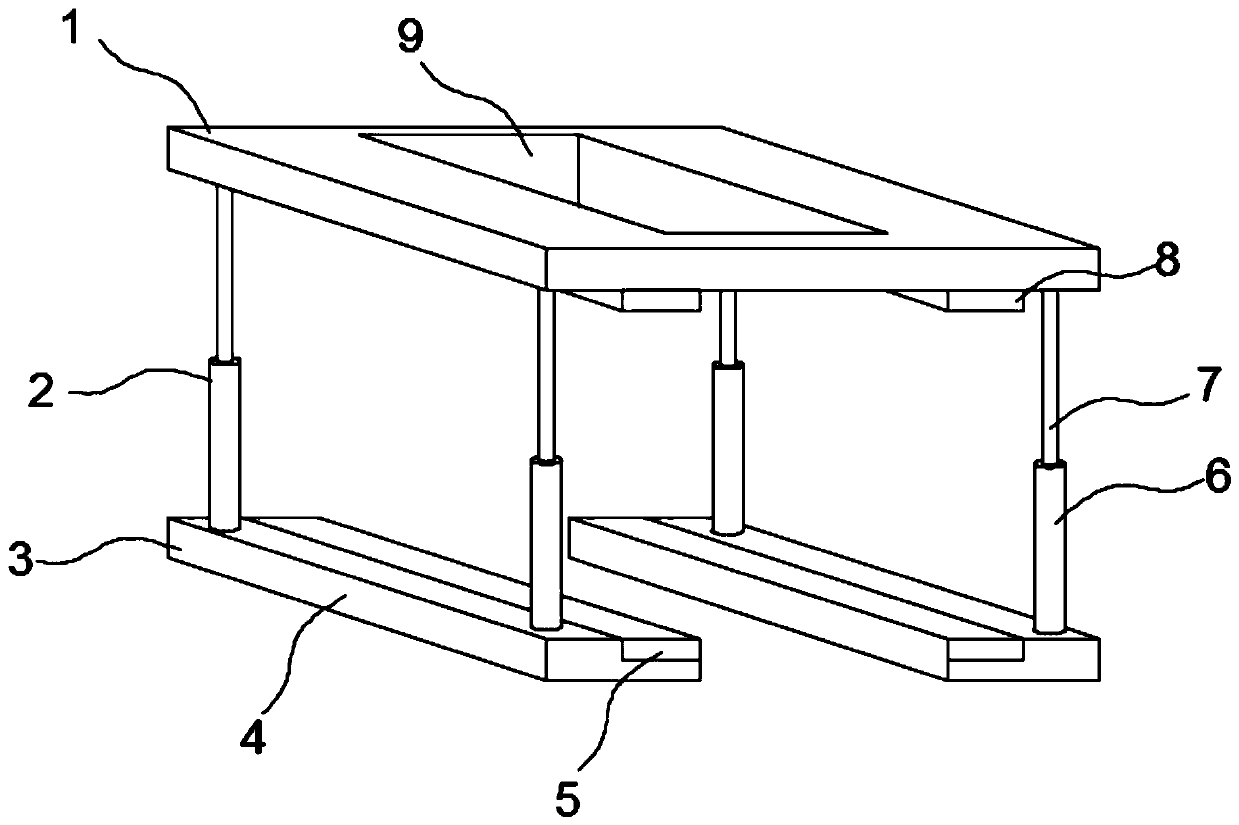

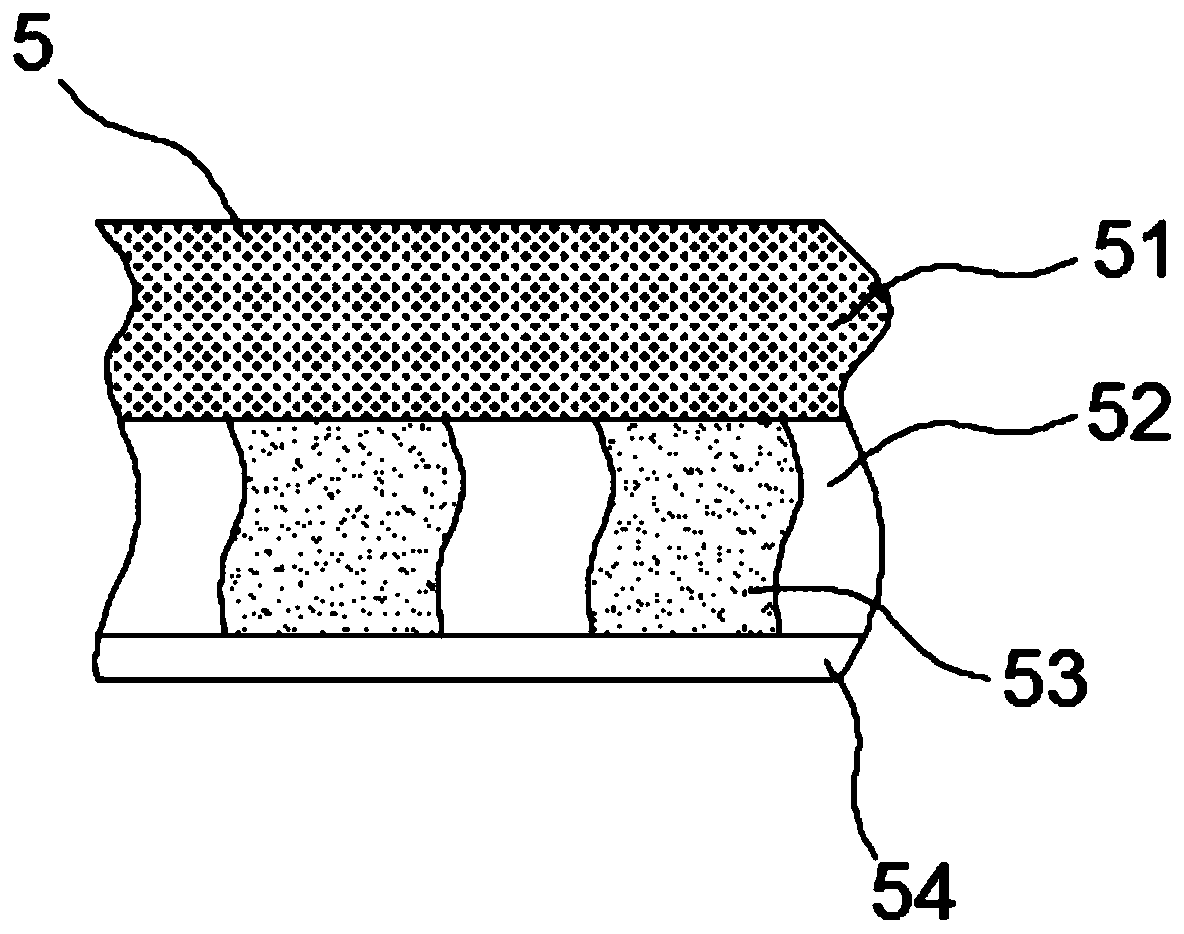

[0047] Such as figure 1 with figure 2 As shown, the soft cushion plate 5 and the clamping cushion 8 are provided with the same mechanism, and the soft cushion plate 5 is fixed by the fixing plate 4.

[0048] Optimally, the soft cushioning board 5 is provided with an upper elastic layer 51, and the material of the upper elastic layer 51 is rubber. A lower elastic layer 52 is provided at the lower end of the upper elastic layer 51, and the lower end of the lower elastic layer 52 is fixed to the bottom. On the pallet 54.

[0049] Optimally, the lower elastic layer 52 is composed of a plurality of elastic members 53, and the elastic member 53 is composed of a rubber tube filled with fine sand.

[0050] Furthermore, the soft cushion plate 5 and the clamping cushion 8 can be realized by the elastic members 53 on the upper elastic layer 51 and the lower elastic layer 52 due to their own flexibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com