Force transmission device for anti-pulling test and detection method of device

A technology of a conduction device and a detection method, which is applied in the measurement device, the use of a stable tension/pressure test material strength, an instrument, etc., can solve the problem of difficult to pull out the bearing capacity detection and other problems, and achieve the effect of convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

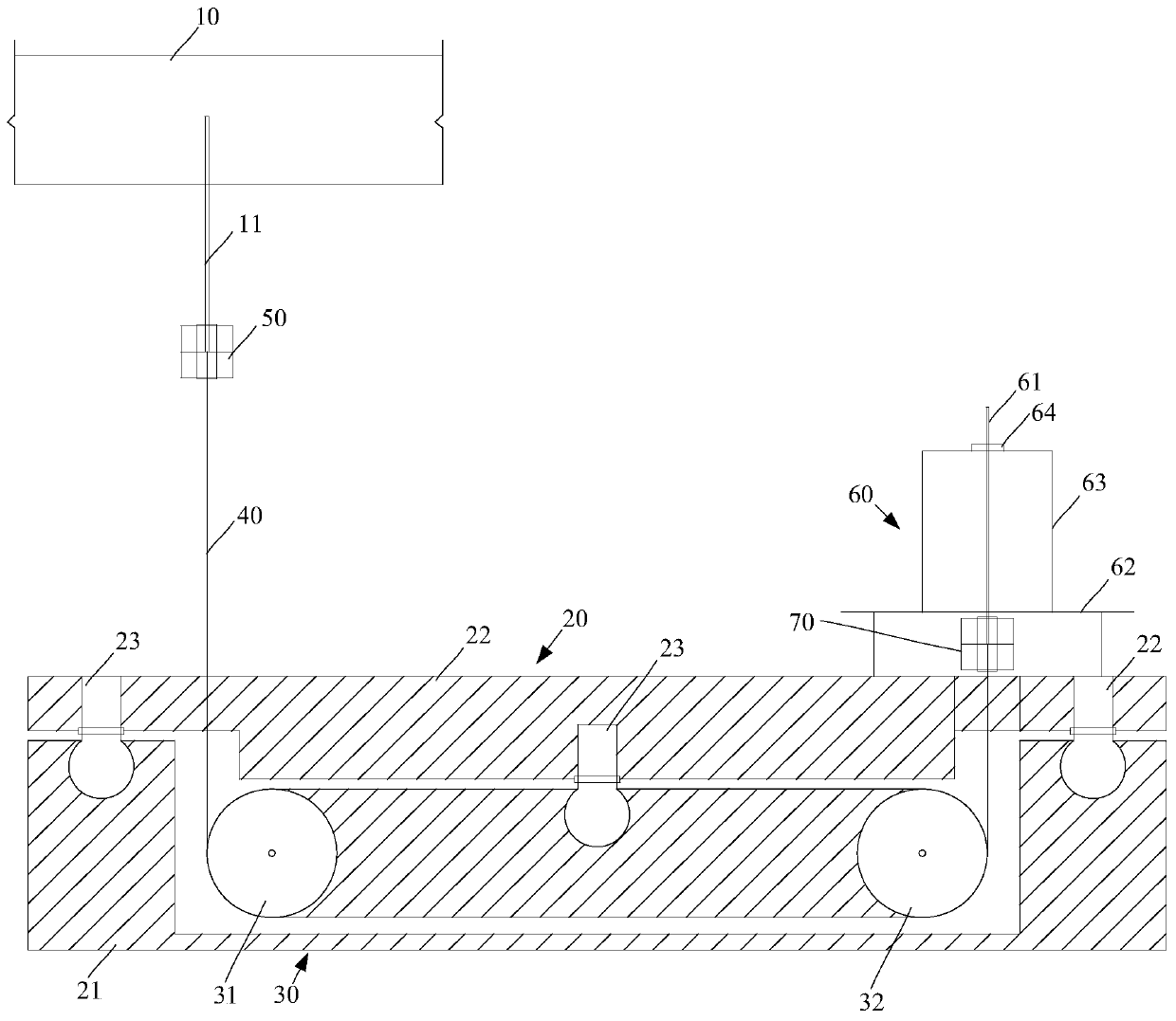

[0057] As a preferred embodiment of the force transmission device used in the pullout test of the present invention, the guide mechanism 30 includes:

[0058] A first fixed pulley 31 rotatably disposed in the base 20 and positioned below the anchor 11; and

[0059] The second fixed pulley 32 is rotatably arranged in the base 20 and located below the limiting member 60 . The centers of the second fixed pulley 32 and the first fixed pulley 31 are located on the same horizontal line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com