High-speed original cable electrical integrity test fixture

A technology for testing fixtures and integrity, which is applied to the components of electrical measuring instruments, measuring devices, measuring electrical variables, etc. It can solve impedance discontinuity, S-parameter distortion, and cannot accurately control the manufacturing capacity of high-speed cables, etc. problem, to achieve the effect of good impedance continuity and avoid parameter distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

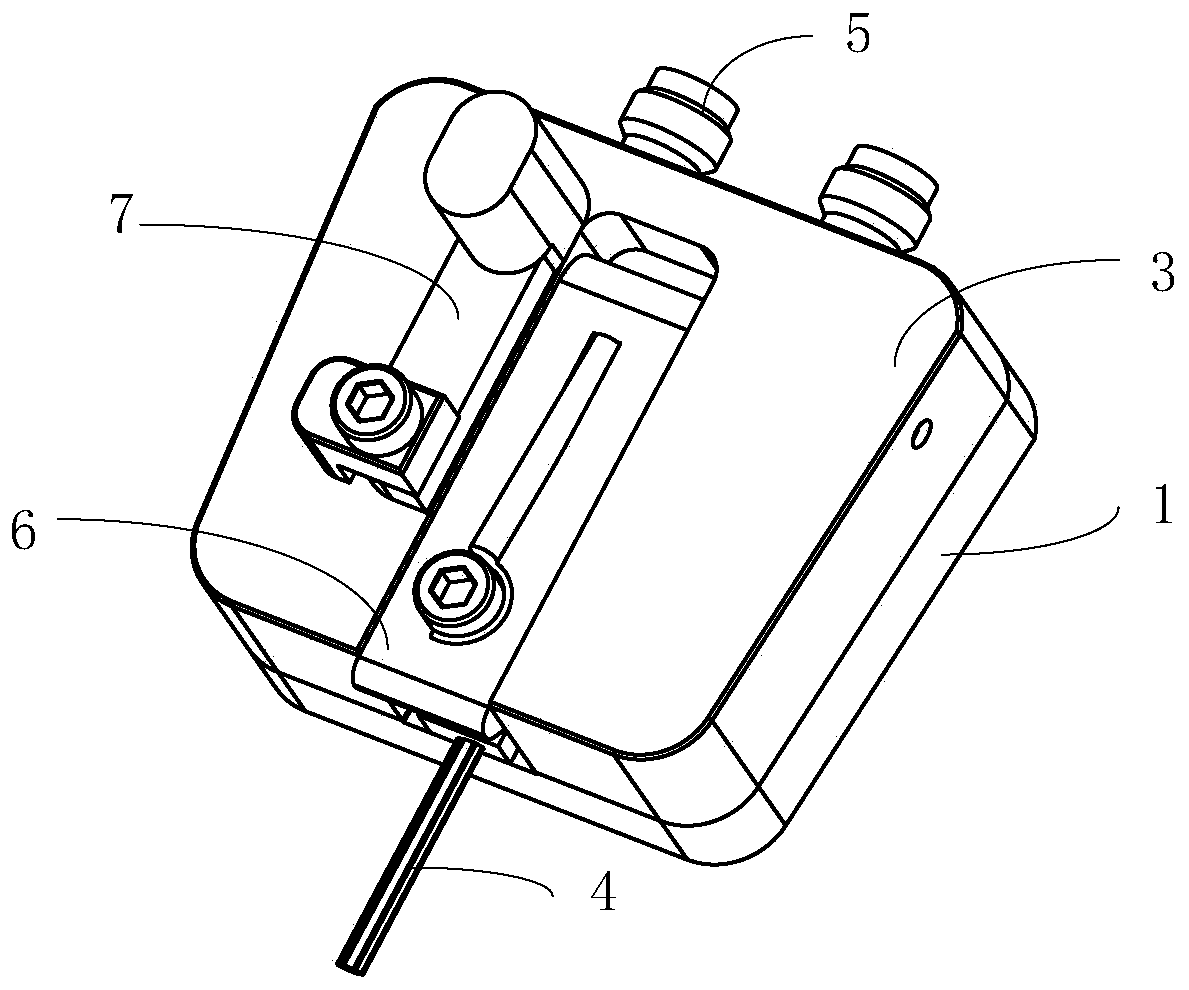

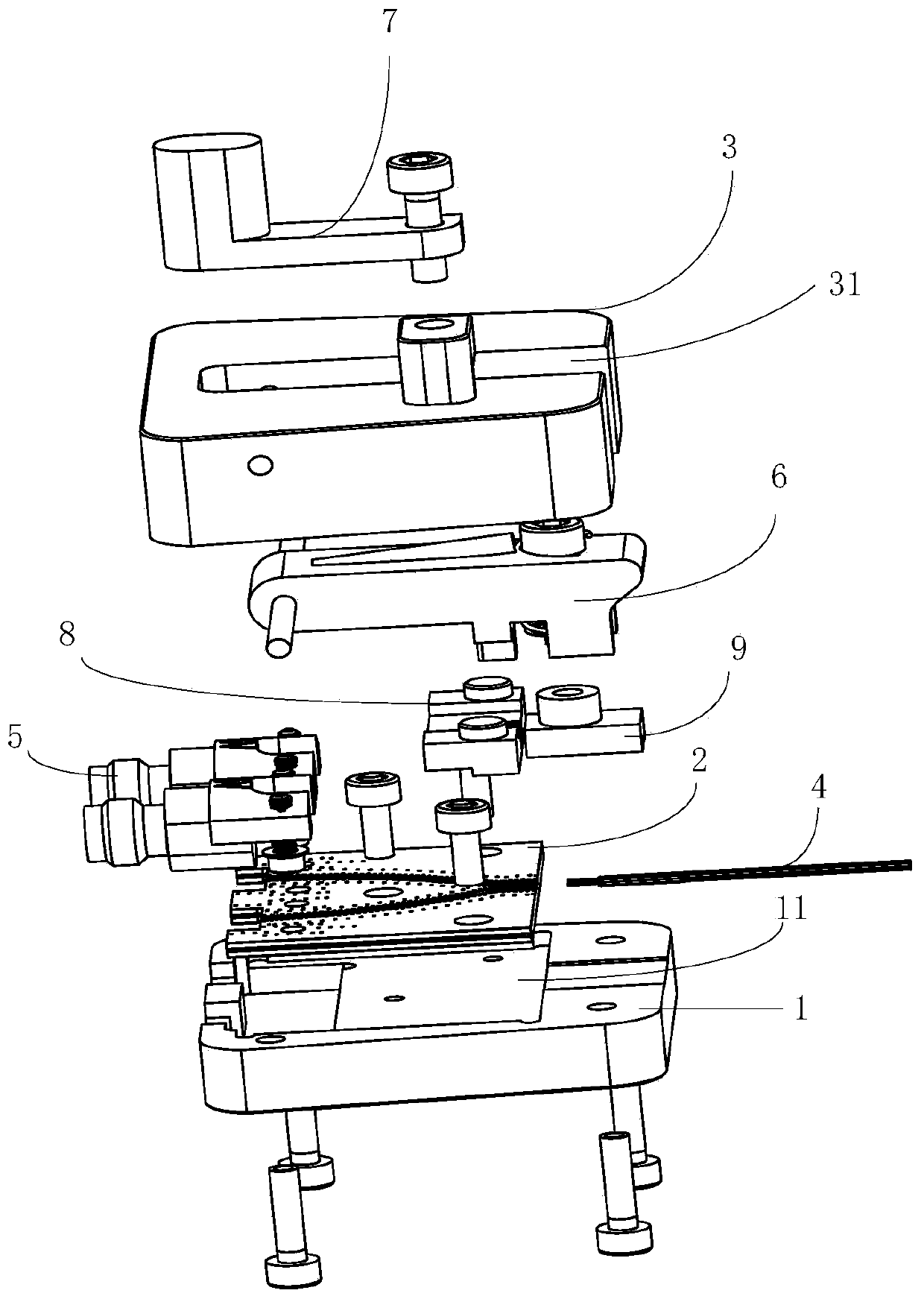

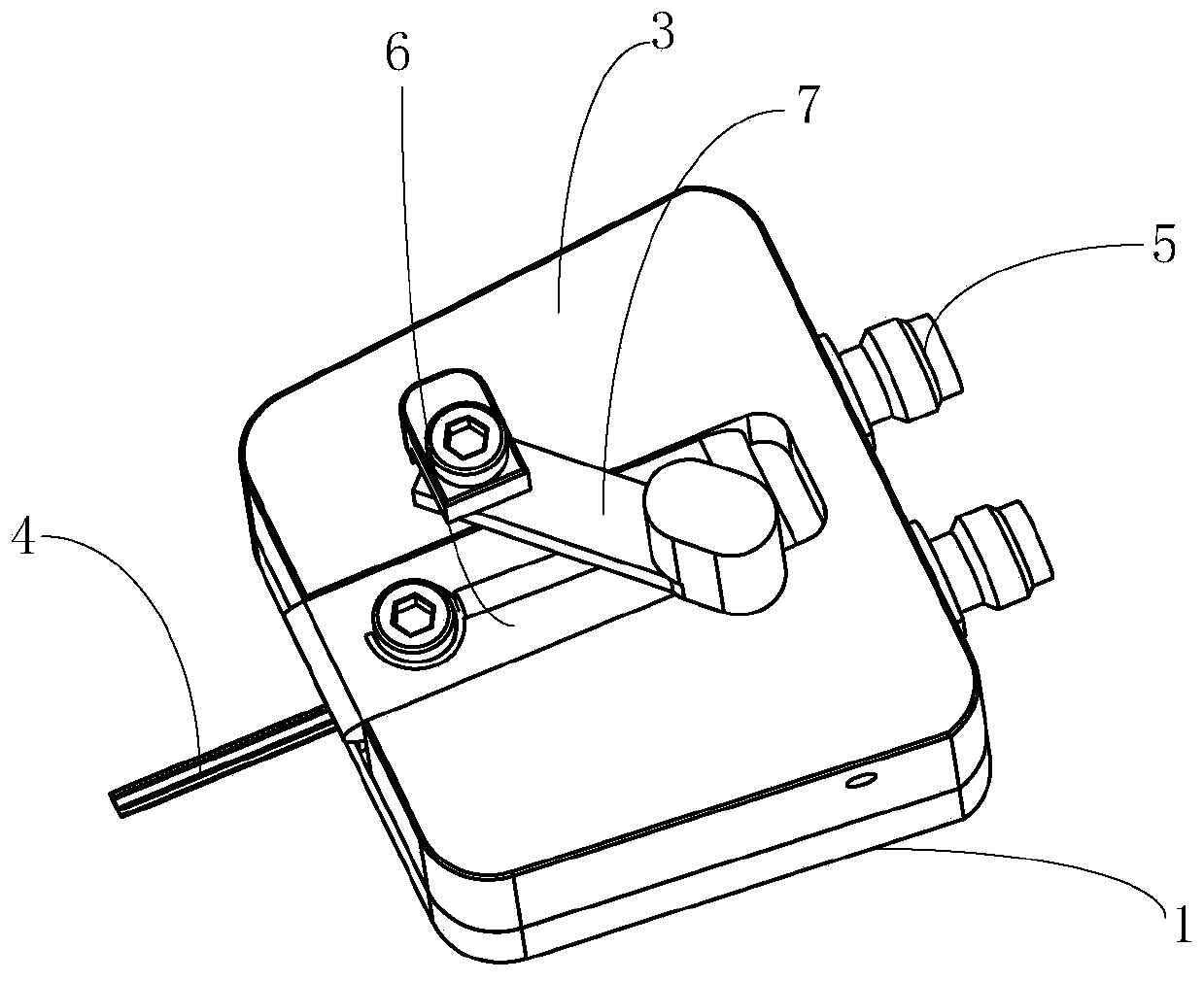

[0083] Such as Figure 1 to Figure 12 As shown, the invention provides a high-speed original cable electrical integrity test fixture, comprising:

[0084] The lower shell 1 is provided with a plate groove 11 on the top of the lower shell 1;

[0085] The PCB board 2, the PCB board 2 is connected in the board groove 11, and the PCB board 2 is provided with a pair of signal lines 21 extending from one end of the PCB board 2 to the other end;

[0086] The upper shell 3, the upper shell 3 is connected to the top of the lower shell 1, and the upper shell 3 is provided with a pressure block 6 groove 31;

[0087] The original cable 4, the original cable 4 is connected to one end of the PCB board 2, the original cable 4 includes a pair of wire ends 41, and each conductive end is electrically connected to a signal line 21;

[0088] A pair of connectors 5, the pair of connectors 5 are connected to the other end of the PCB board 2, and each connector 5 is electrically connected to a sig...

Embodiment 2

[0107] When using the high-speed original cable electrical integrity test fixture involved in the present invention to test the original cable 4 of a certain specification, the test result curve is judged by the frequency band on the abscissa and the attenuation value of the wire on the ordinate. The smoother the curve, the test result The better, by replacing the connector 5 with different specifications, the test fixture is suitable for testing in different frequency bands, so as to meet the requirements for test parameters and avoid distortion of some parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com