Water surface cleaning machine

A cleaning machine and machine body technology, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of unable to collect garbage quickly, garbage is easily carried out by water flow, and garbage storage effect is poor, so as to achieve easy processing and realization, zero waste Less parts, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

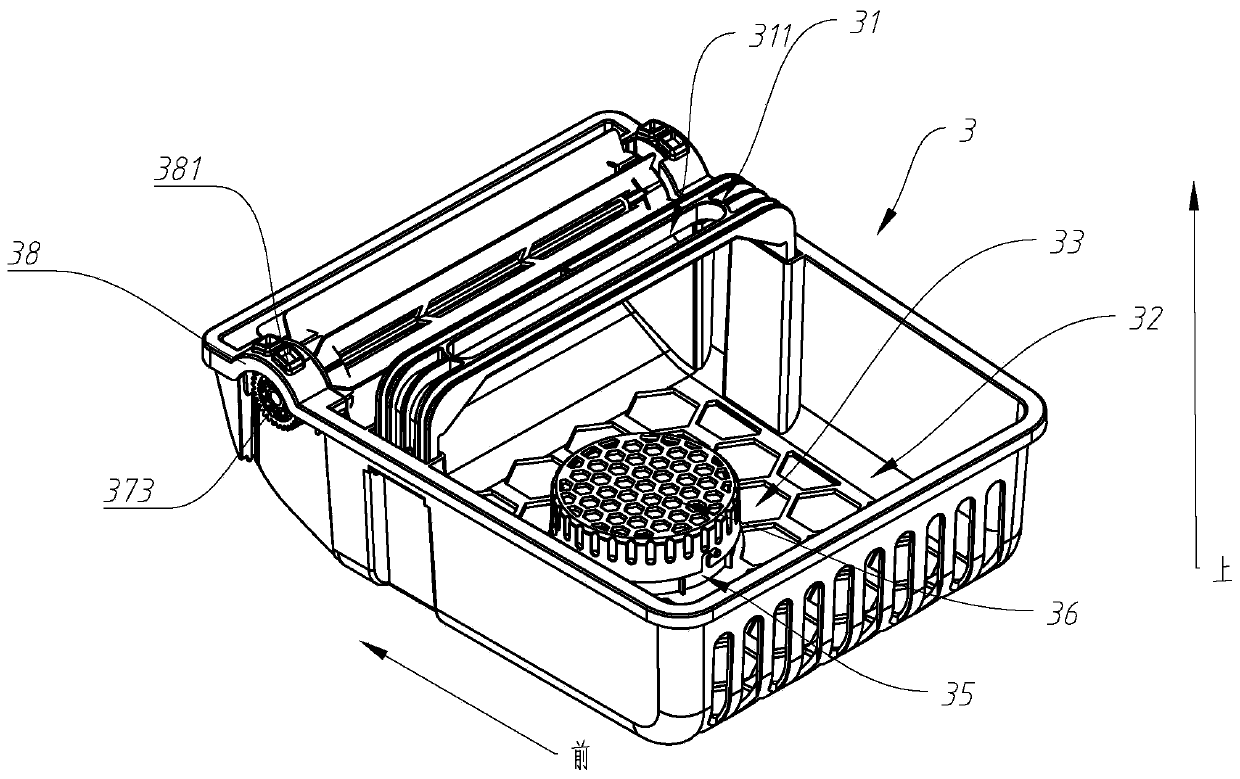

[0092] The sheet structure 371 is a strip-shaped blade; the upper edge of the strip-shaped blade is higher than the upper edge of the storage part 3, so that the driven garbage can automatically fall into the storage part 3 under the action of water flow and gravity. In the cavity, the structure is simple and practical.

[0093] The vertical projection of the elongated blade and the upper opening of the receiving part 3 at least partially overlaps, so that the driven garbage directly falls into the inner cavity of the receiving part 3, effectively preventing the garbage from falling.

[0094] A specific embodiment of adding a drive source in the present invention:

[0095] The rolling member 372 is assembled on the upper end of the receiving member 3 and connected to a driving source.

[0096] The driving source is assembled on the machine body 1 and connected with the rolling element 372 through a gear set.

[0097] Due to the limited structural space of the receiving part ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap