Equipment suitable for testing performance of air valve of railway vehicle air conditioning unit

A technology for air-conditioning units and testing equipment, which is applied in the direction of mechanical valve testing, measuring electricity, and measuring devices. It can solve the problems of inconvenient disassembly and assembly, repeated disassembly and installation of damper tests, and inconvenient adjustment of parameters. The effect of improving maintenance efficiency and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

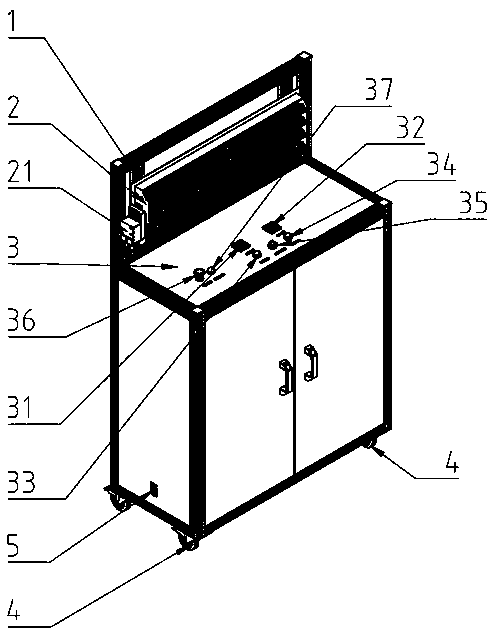

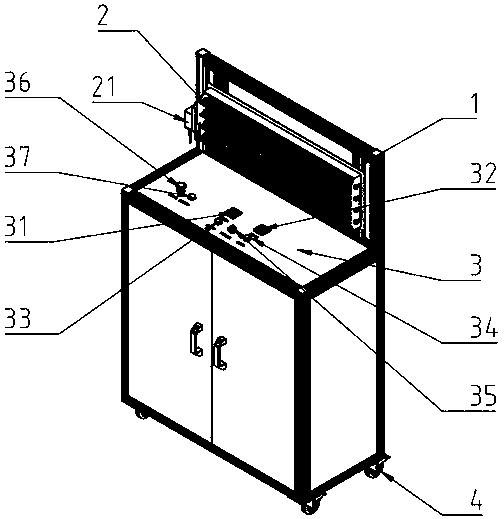

[0020] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0021] Such as Figure 1-Figure 3 As shown, the present embodiment provides a kind of test equipment suitable for the air valve performance of rail vehicle air-conditioning units, including a test bracket 1 and an operating platform 3, and the testing bracket 1 is installed on the side above the operating platform 3, and the testing bracket 1 is used to install the air valve 2, and the operation platform 3 is equipped with a forward rotation timer 31, a reverse rotation timer 32, a forward rotation switch 33 and a reverse rotation switch 34, and the forward rotation timer 31 and the forward rotation switch 33 Electrically connected to control its power-on time, the reverse timer 32 is electrically connected to the reverse switch 34 to control its power-on time, the air valve actuator 21 on the air valve 2 is electrically connected to a forward and reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com