Double-filling high-yield capsule filling machine

A high-yield, filling machine technology, applied in the direction of capsule delivery, drug delivery, pharmaceutical formulations, etc., can solve the problems of accelerated wear of equipment parts, reduce equipment life, and small adjustment range, so as to achieve large space occupation and low purchase cost , to meet the effect of high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

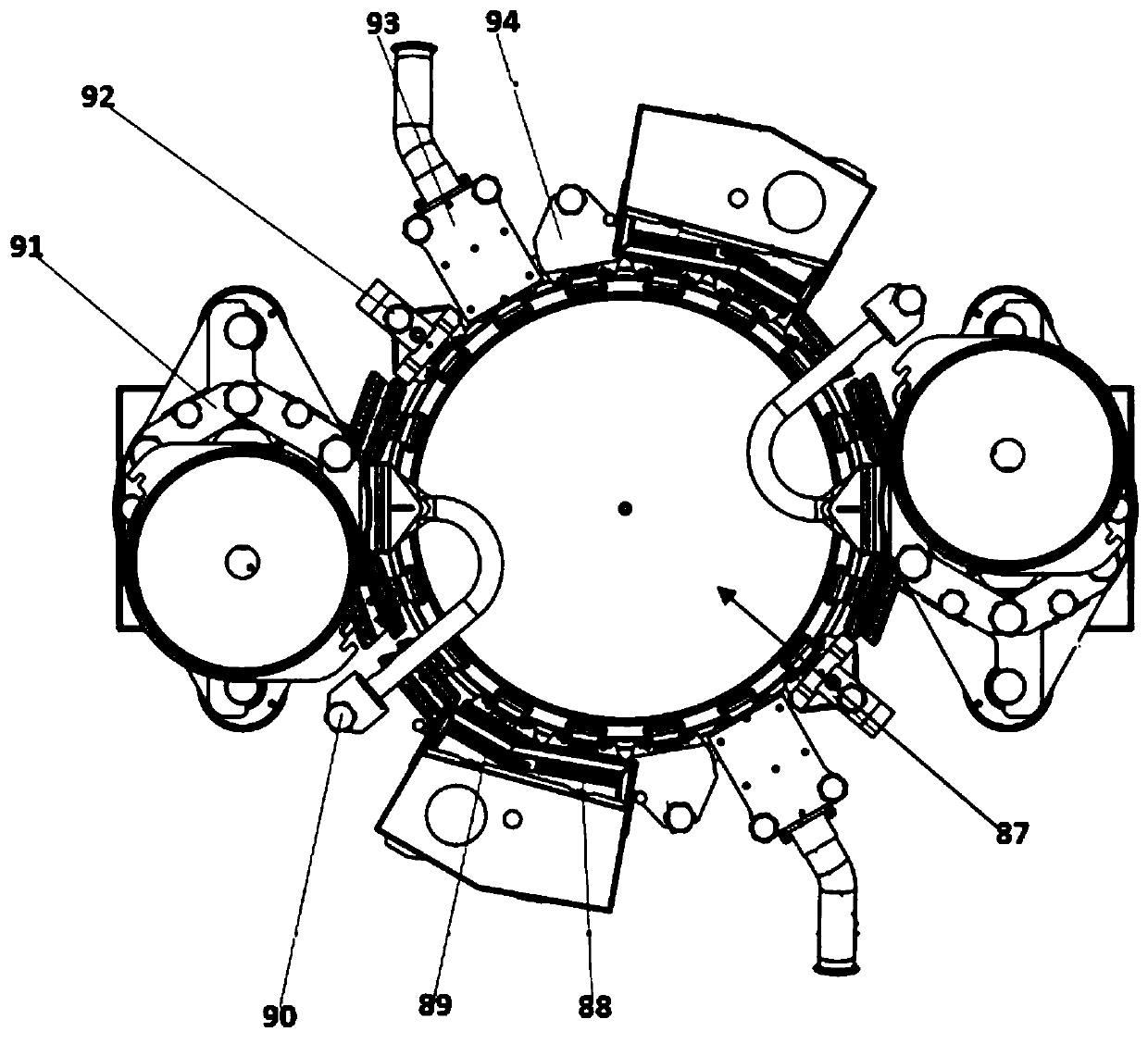

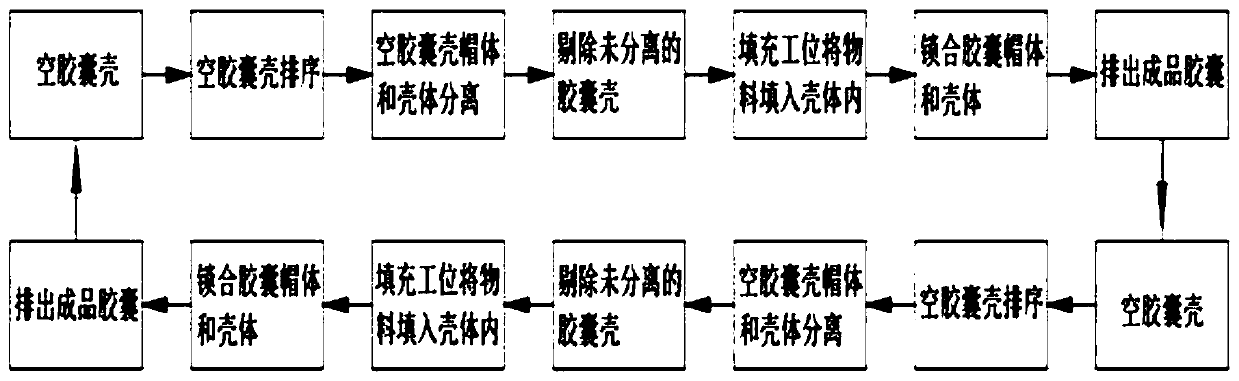

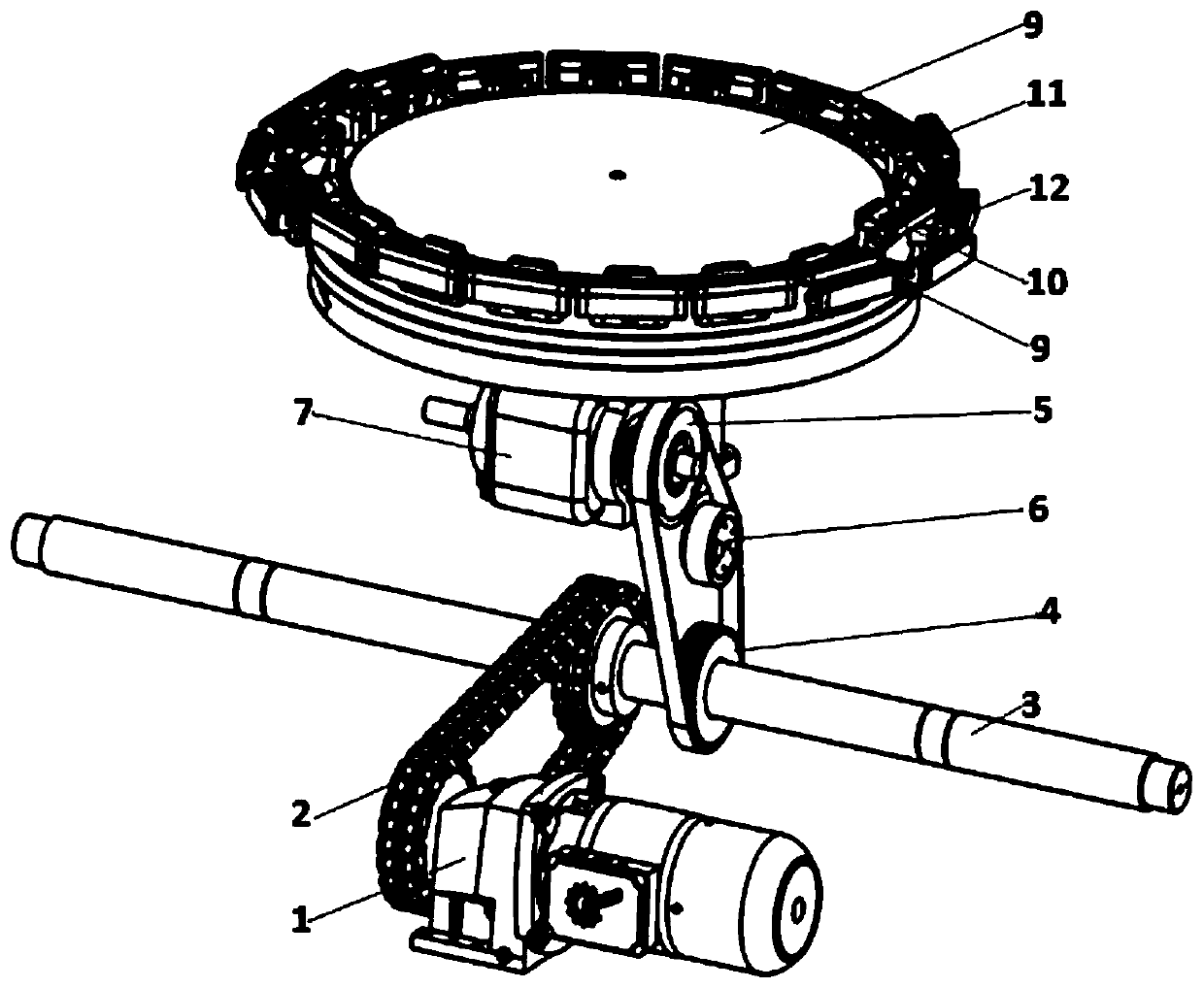

[0035] Such as Figure 1-12 As shown, a double-filled high-yield capsule filling machine includes a central turret 87, a first capsule filling mechanism and a second capsule filling mechanism, and the first capsule filling mechanism and the second capsule filling mechanism are respectively arranged on both sides of the central turret 87. The second capsule filling mechanism, the first capsule filling mechanism and the second capsule filling mechanism have the same structure except for the installation position, and the first capsule filling mechanism includes a first capsule sorting and separating mechanism 88, a second capsule sorting and separating mechanism 89. Waste rejection mechanism 90, filling mechanism 91, capsule combining mechanism 92, finished capsule discharge mechanism 93, upper and lower mold cleaning mechanism 94, the first capsule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com