Modified yeast comprising glucose-specific, ATP-mediated transporters

A technology for transporting proteins and glucose, applied in fermentation, biofuels, peptide sources, etc., can solve problems such as reducing cell robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0111] Materials and Methods

[0112] Liquefaction preparation:

[0113] The liquefied product (corn flour slurry) was added by adding 600ppm urea, 0.124SAPU / g ds FERMGEN TM (Acid fungal protease) 2.5x, 0.33 GAU / g ds TrGA (Trichoderma glucoamylase) and 1.46 SSU / g dsAKAA (Aspergillus alpha-amylase), adjusted to pH 5.4.

[0114] Serum Bottle Assay:

[0115] Yeast cells were inoculated into 2 mL of YPD in a 24-well plate, and the culture was grown overnight to an OD between 25-30. 2.5 mL of liquefied fluid was transferred to serum vials (Chemglass, Cat. No.: CG-4904-01 ), and yeast was added to each vial to a final OD of approximately 0.4-0.6. Install the cap of the vial and pierce it with a needle (BD, Cat. No. 305111) for ventilation (to release CO 2 ), and then incubated at 32°C for 65 hours with shaking at 200RPM.

[0116] AnKom assay:

[0117] 300 μL of the concentrated overnight yeast culture was added to each of multiple ANKOM bottles filled with 50 g of the prepared...

example 2

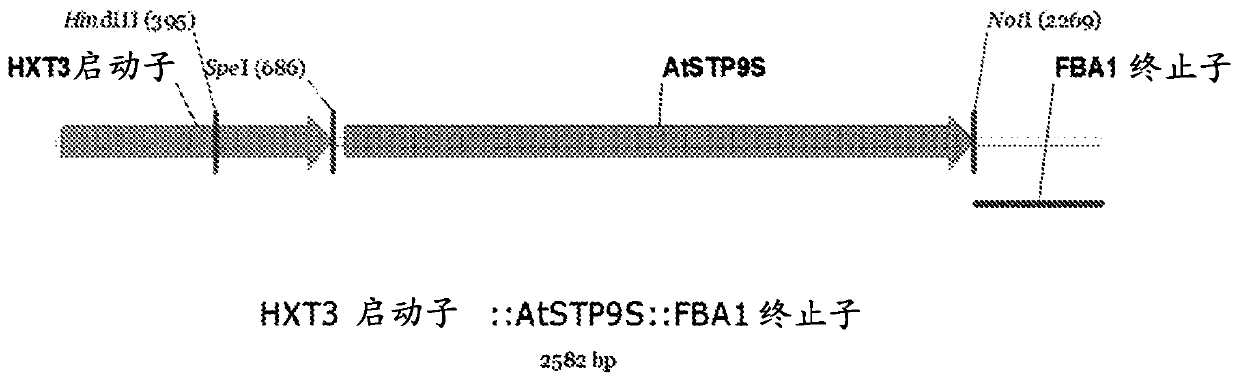

[0121] Constructs for overexpression of codon-optimized, glucose-specific, ATP-mediated transporter The gene for glucose-specific, ATP-mediated transporter 9 (AtSTP9) from Arabidopsis thaliana was codon-optimized and then synthesized as Generate AtSTP9S. The nucleotide and amino acid sequences of AtSTP9S and its expression product AtSTP9S are shown as the following SEQ ID NO: 1 and SEQ ID NO: 2, respectively.

[0122] Nucleotide sequence of AtSTP9S gene (SEQ ID NO: 1):

[0123] ATGGCTGGTGGTGCCTTTGTCTCCGAAGGTGGCGGTGGAGGCAACTCTTACGAAGGTGGCGTTACCGTCTTTGTTATCATGACCTGTATTGTTGCCGCTATGGGAGGTTTGCTATTTGGTTACGACTTGGGTATCTCTGGCGGTGTCACCTCTATGGAAGAGTTCTTGTCCAAGTTTTTCCCAGAAGTTGACAGACAAATGCACGAAGCCAGACGTGAAACTGCTTACTGCAAGTTCGATAACCAATTGCTACAATTGTTCACCTCTTCCTTGTACTTGGCTGCCTTAGTCTCTTCCTTTGTTGCTTCTGCTGTCACCAGAAAGTACGGTAGAAAGATTTCCATGTTTGTTGGTGGCGTCGCTTTCTTGATCGGTTCTTTGTTCAACGCCTTTGCTACCAACGTTGCTATGTTGATCATTGGTAGATTGCTATTGGGTGTCGGCGTCGGTTTTGCTAATCAATCTACTCCAGTTTACTTGTCCGAAATGGCTCCAGCCAAGATCAGAG...

example 3

[0136] Generation of yeast strains expressing glucose-specific, ATP-mediated transporters

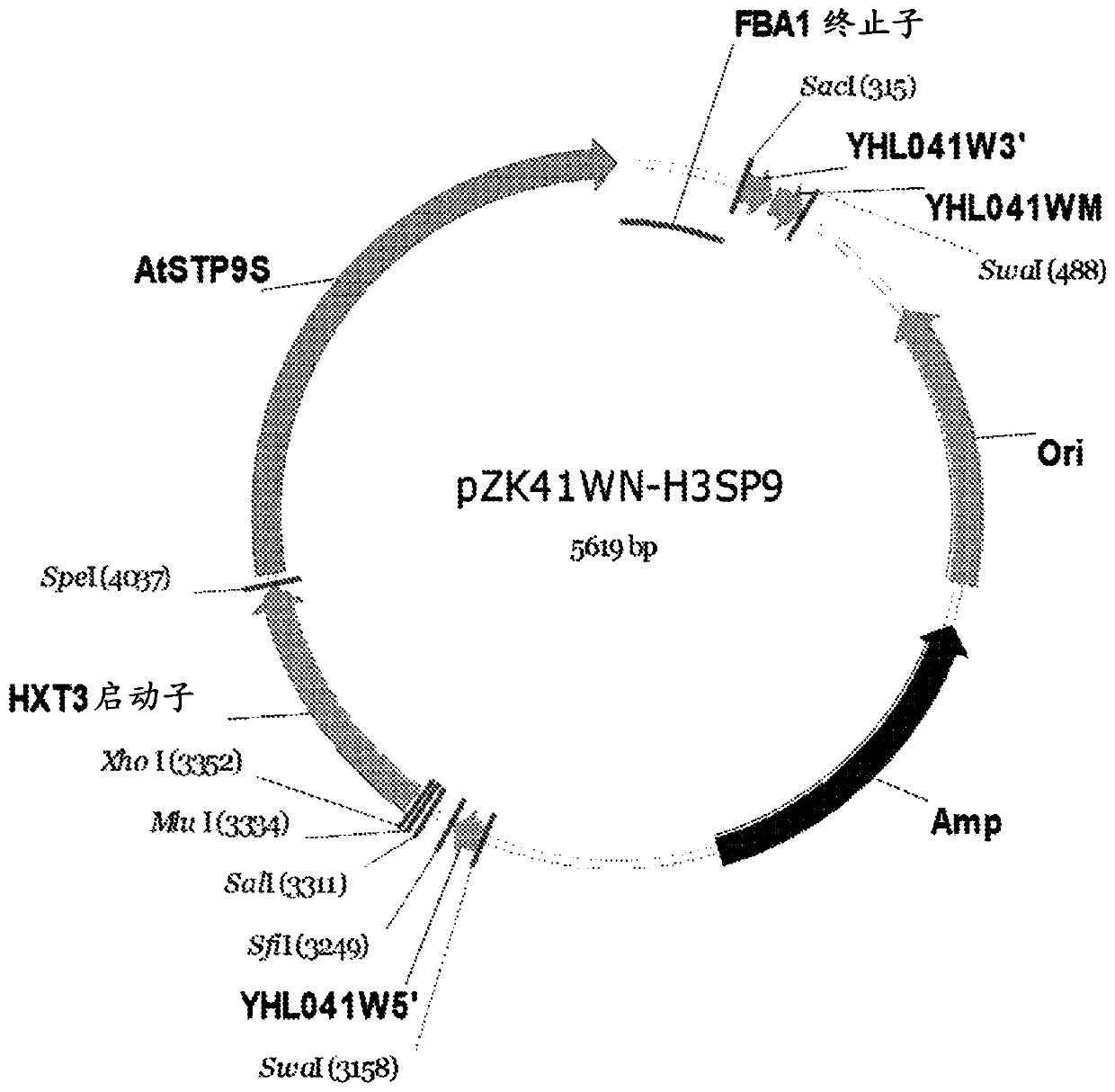

[0137] Will The GOLD yeast strain (Martrex, Inc., MD, USA; referred to herein as "FG") was used as a parental strain to introduce the AtSTP9S expression cassette. With containing from the plasmid pZK41Wn-H3SP9 ( figure 2 The 2,949bp SwaI fragment of the AtSTP9S expression cassette of ) and the plasmid pYRH426 transformed the cells. A transformant that integrated the SwaI fragment from pZK41Wn-H3SP9 downstream of the YHL041W locus was selected and named strain G027.

[0138] The new FG yeast strain G027 was grown in vial cultures together with its parental strain FG, and its fermentation products were analyzed as described in Example 1. Properties for ethanol, glycerol and acetic acid production are shown in Table 3.

[0139] Table 3. Comparison of FG and G027 in vial assays

[0140]

[0141] Strain G027 produced approximately 2% more ethanol than the parental strain and produc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap