Stainless steel pipe heat treatment quenching equipment

A technology for quenching equipment and stainless steel tubes, applied in heat treatment equipment, heat treatment furnaces, quenching devices, etc., can solve problems such as difficulty in ensuring quenching quality, inability to quickly eliminate vapor film, and the influence of quenching cooling speed, achieving radial uniformity and cooling. The effect of uniform and reduced vapor film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

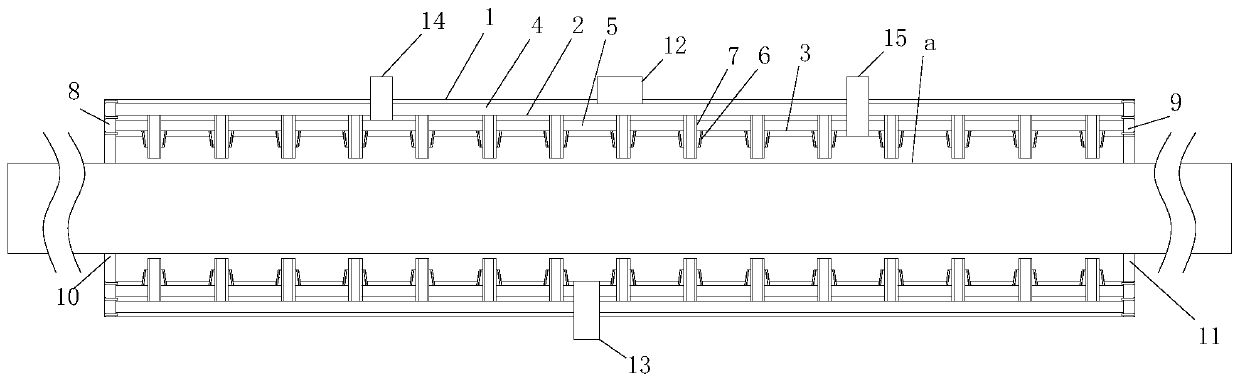

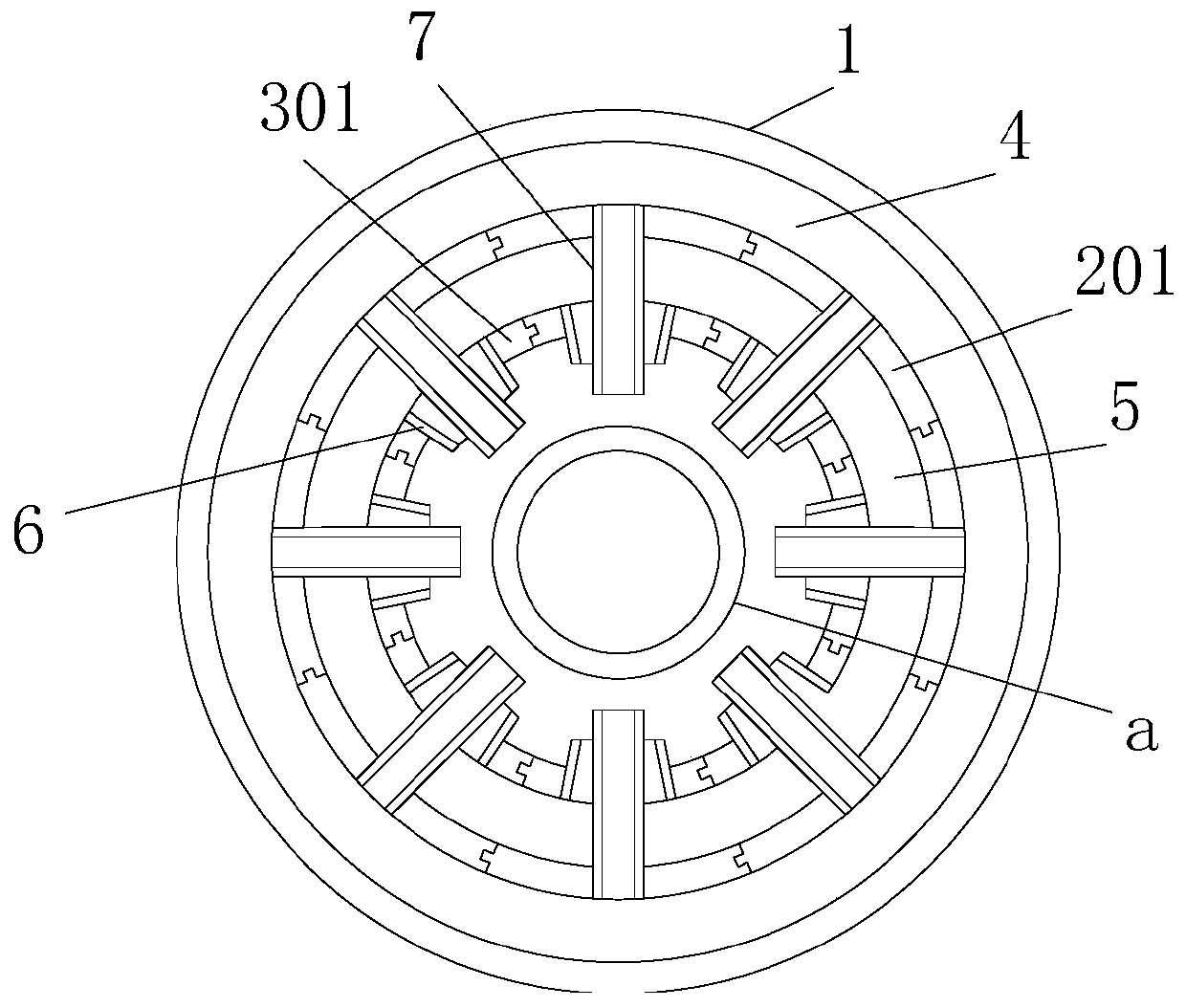

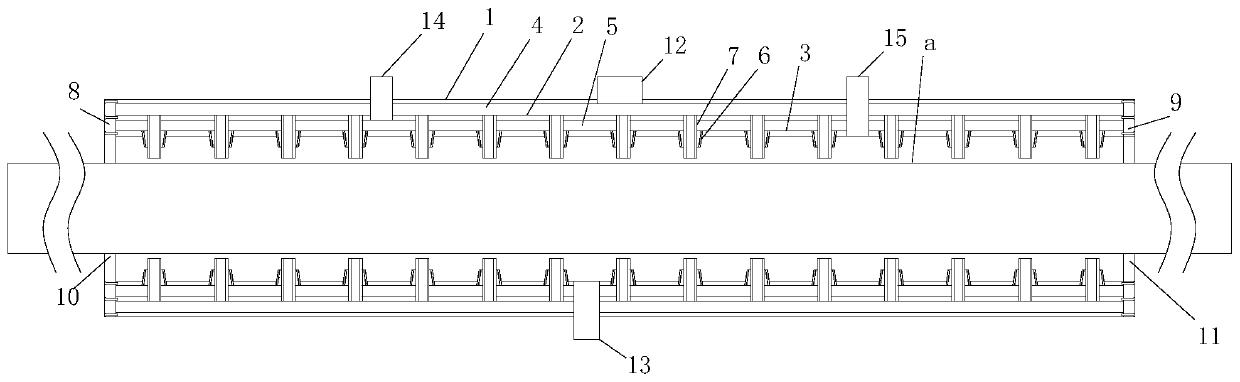

[0017] refer to figure 1 , figure 2 , the present invention proposes a heat treatment and quenching equipment for stainless steel tubes, including an outer cylinder 1, a water inlet pipe 12, a water outlet pipe 13, an air inlet pipe 14 and an air outlet pipe 15, and the outer cylinder 1 is provided with a first inner cylinder 2 and a second inner cylinder 3 .

[0018] The first end of the outer cylinder 1 is provided with a first pressing plate 8, and the ends of the outer cylinder 1, the first inner cylinder 2, and the second inner cylinder 3 are all connected to the first pressing plate 8 by a plurality of screws, and the first pressing plate A steel pipe inlet 10 communicating with the inside of the second inner cylinder 3 is provided on the tight plate 8 . The second end of the outer cylinder 1 is provided with a second pressing plate 9, and the ends of the outer cylinder 1, the first inner cylinder 2, and the second inner cylinder 3 are all connected to the second pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com