Self-moving device of repeated-free supporting unit bracket

A support unit, self-moving technology, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

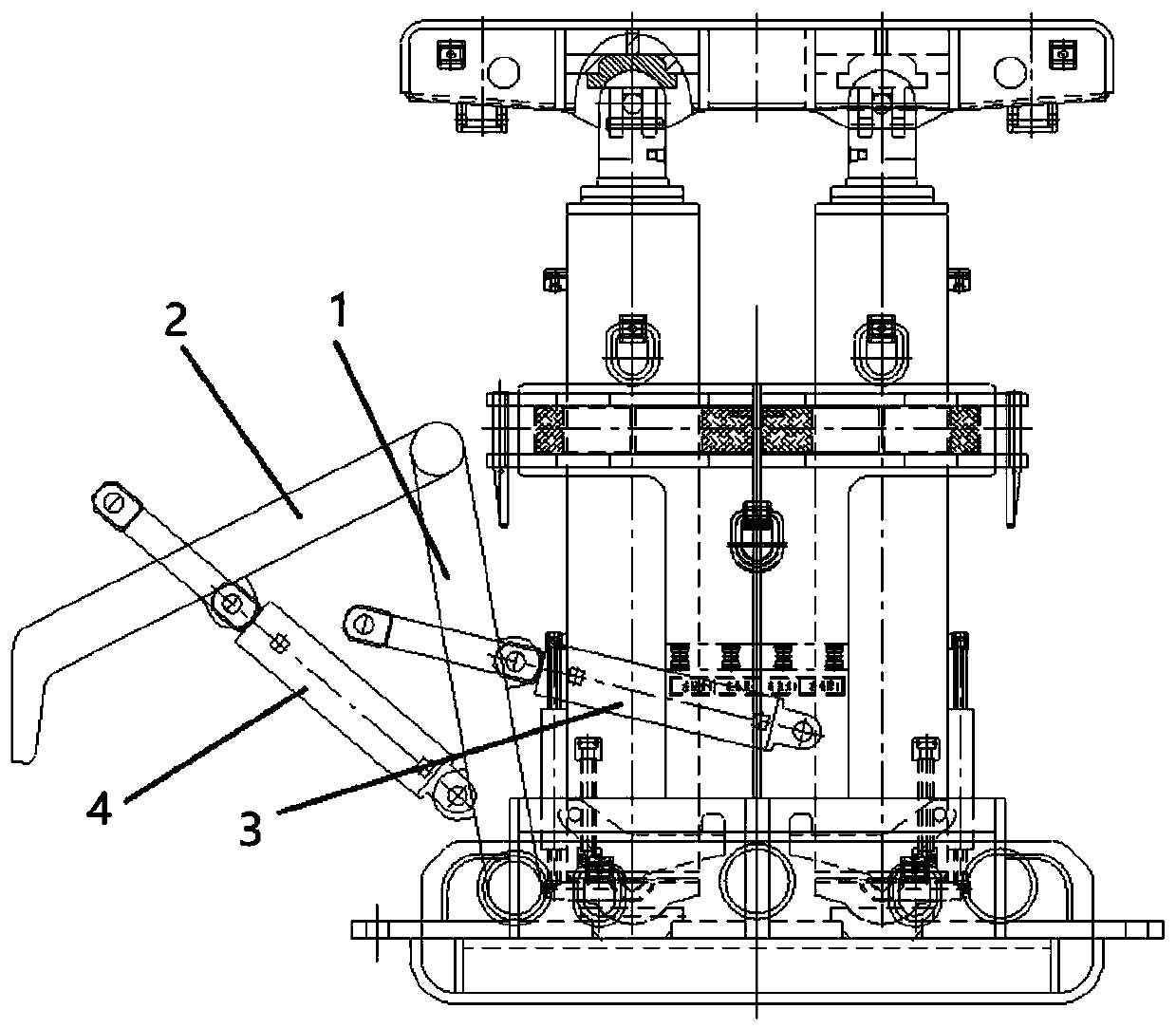

[0025] Such as figure 1 As shown, the self-moving non-repeating support unit support of the present invention is compared with the unit support of the prior art. Two sets of pulling jacks and support walking arms are arranged on the support base, and the two sets of pulling jacks are controlled by the operating valve to move The arm stretches forward-swings-pulls back to realize the self-moving function of the unit bracket.

[0026] The present invention can adjust the stroke of the jack, the length of the walking support arm and the hinge points of the relevant connection elements to meet the requirements of the moving speed of the unit support under different working conditions, so as to meet the normal use requirements of the support.

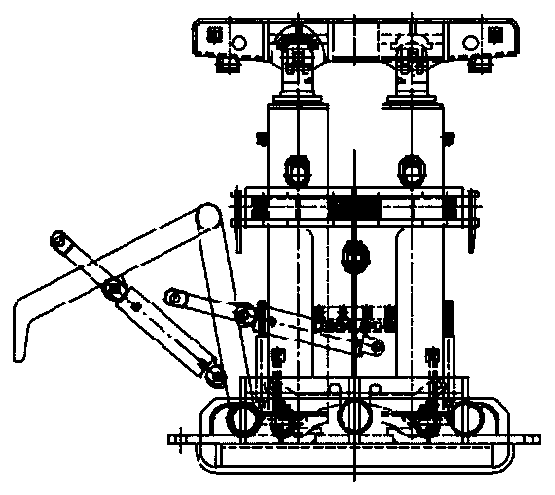

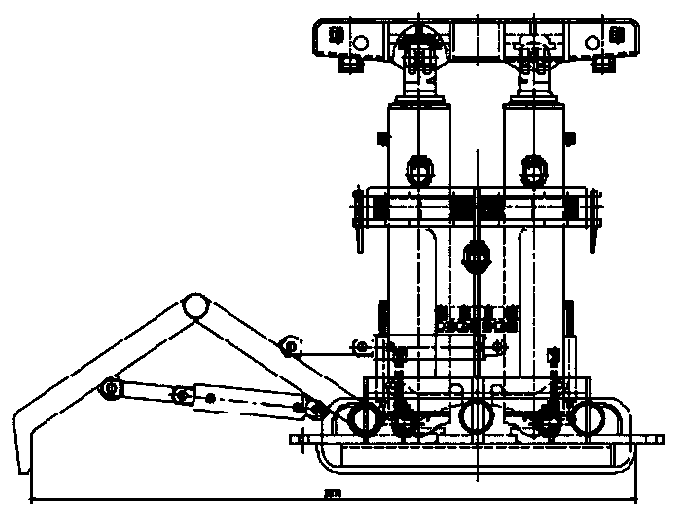

[0027] Such as Figure 2a , Figure 2b , Figure 2c As shown in the figure, it is the flow chart of moving the self-moving non-repeatable support unit bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com