A multi-directional self-moving sliding shoe hydraulic support for coal mine roadway

A technology of coal mine roadway and hydraulic support, which is applied to mine roof support, mining equipment, earth-moving drilling and other directions, can solve the problems of wasting manpower, material resources and time, single transportation direction, deviation, etc. The effect of changeable and good carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

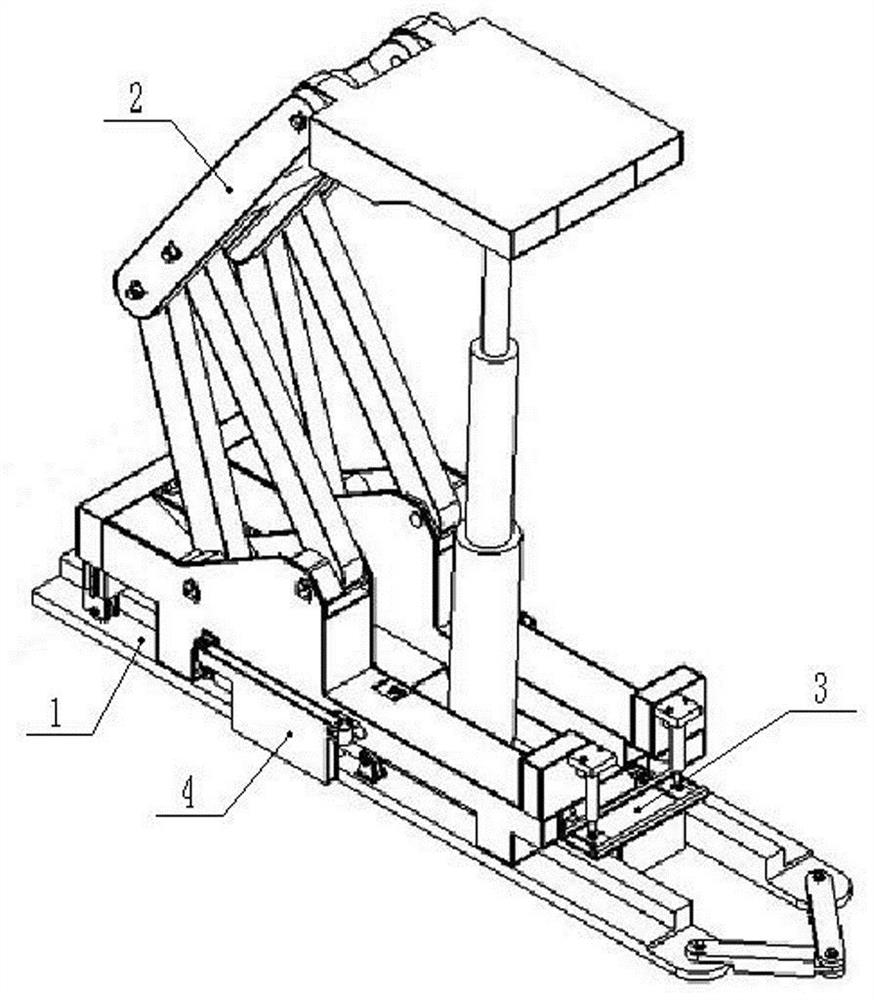

[0035] like figure 1 As shown, a coal mine roadway multi-directional self-moving sliding shoe hydraulic support of the present invention includes a stepping structure 1, a lifting support structure 2, a steering structure 3 and an anti-rolling structure 4;

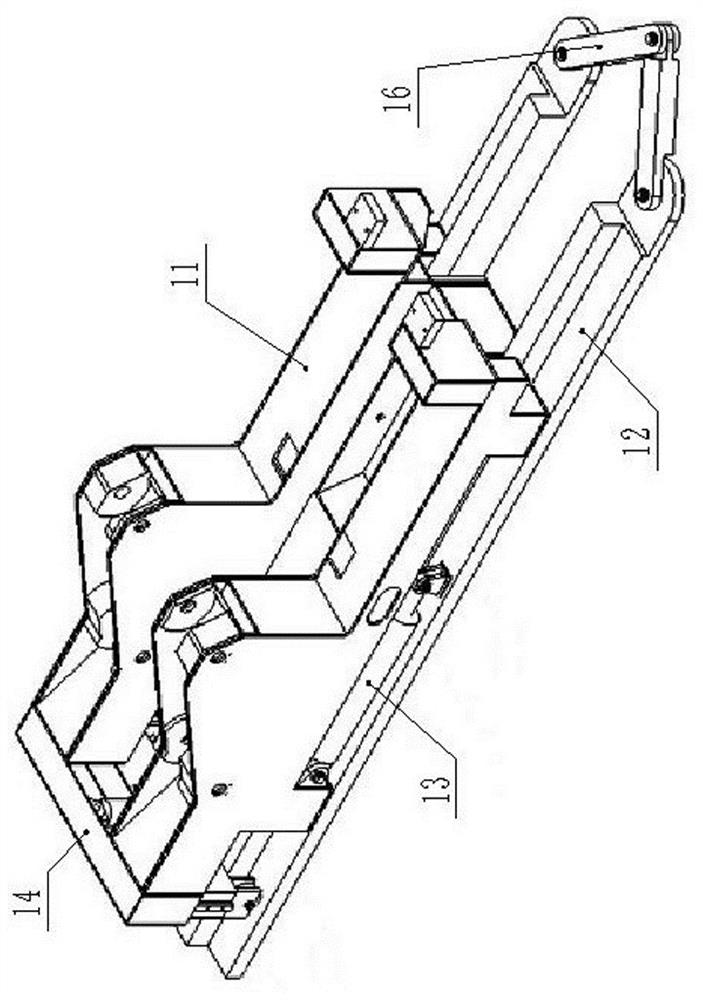

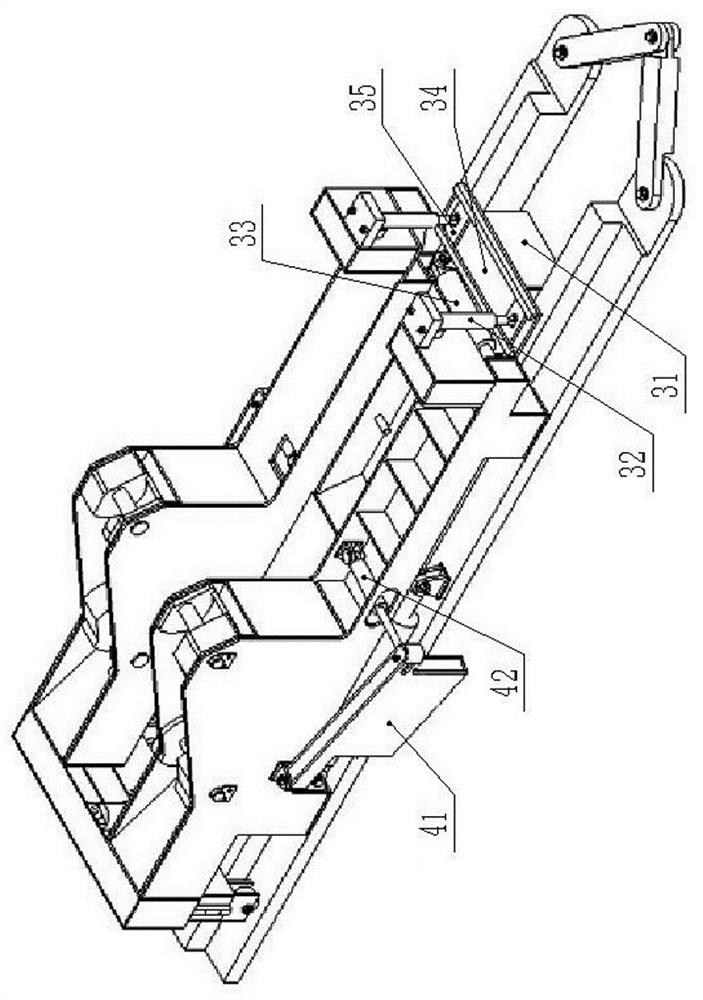

[0036] The stepping structure 1 comprises a support base 11, a track 12, a pushing jack 13 and a bottom lifting structure 14, two tracks 12 are arranged in parallel, the support base 11 is placed on the two tracks 12 and the bottom of the support base 11 contacts the ground, and the two tracks 12 are arranged in parallel. Two moving jacks 13 are installed corresponding to two rails 12, one end is hinged on the support base 11, and the other end is hinged on the track 12, and the bottom lifting structure 14 includes an upper box body 141, a lower box body 142, a bottom lifting jack 143 and rollers 144, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com