Intelligent self-moving device for secondary transfer of fully-mechanized coal winning machine

A self-transporting and self-moving technology of fully mechanized excavators, which is applied in transportation and packaging, slitting machinery, underground transportation, etc., can solve the problems of cost increase, tail deviation, and high risk, and achieve reasonable design, weight reduction, easy cleanup effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] best practice

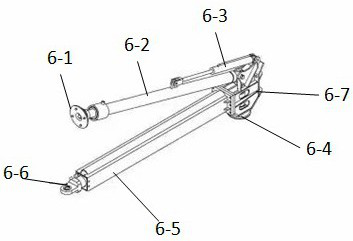

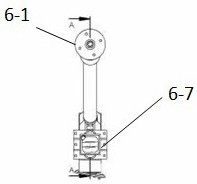

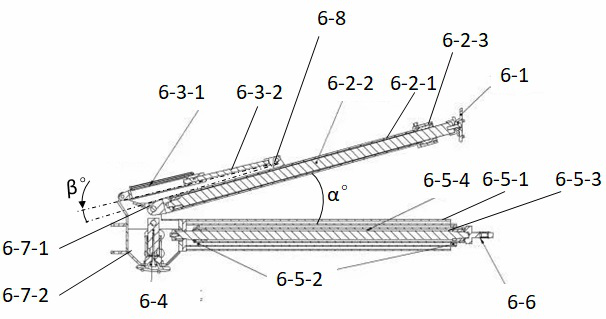

[0036] Such as Figure 1-3 As shown, the present invention provides an intelligent self-moving device for a fully mechanized excavator with two rotations. -8. Anti-sinking oil cylinder 6-4, traction oil cylinder 6-5, one-way adjustment bearing 6-6, coupler 6-7, the traction oil cylinder 6-5 is set horizontally,

[0037] Described closing column oil cylinder 6-2 comprises closing column oil cylinder barrel 6-2-1, closing column oil cylinder telescopic rod 6-2-2, telescopic rod limit sleeve 6-2-3, and described closing post oil cylinder telescopic rod 6 -2-2 One end is inserted into the inside of the cylinder cylinder 6-2-1, one end is ball-connected with the universal guard plate 6-1, and the telescopic rod limit sleeve 6-2-3 is set on the The outlet of the cylinder barrel 6-2-1 of the closing column is used to limit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com