Fire-resisting breather valve

A breathing valve and fire-blocking technology, which is applied in the field of breathing valves, can solve the problems of not being simple and convenient enough, and the installation process is complicated, and achieve the effects of simple installation, avoiding accidents, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

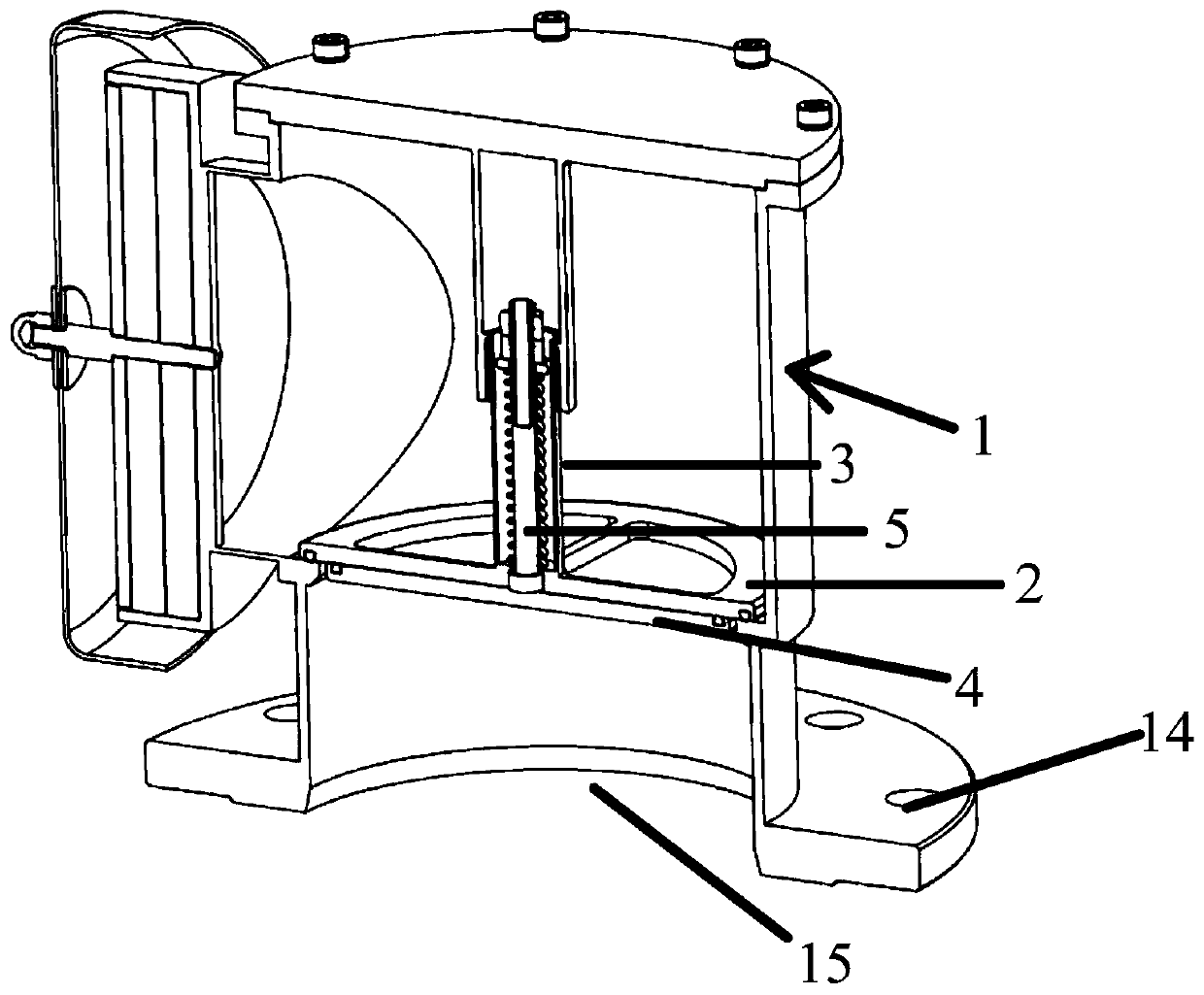

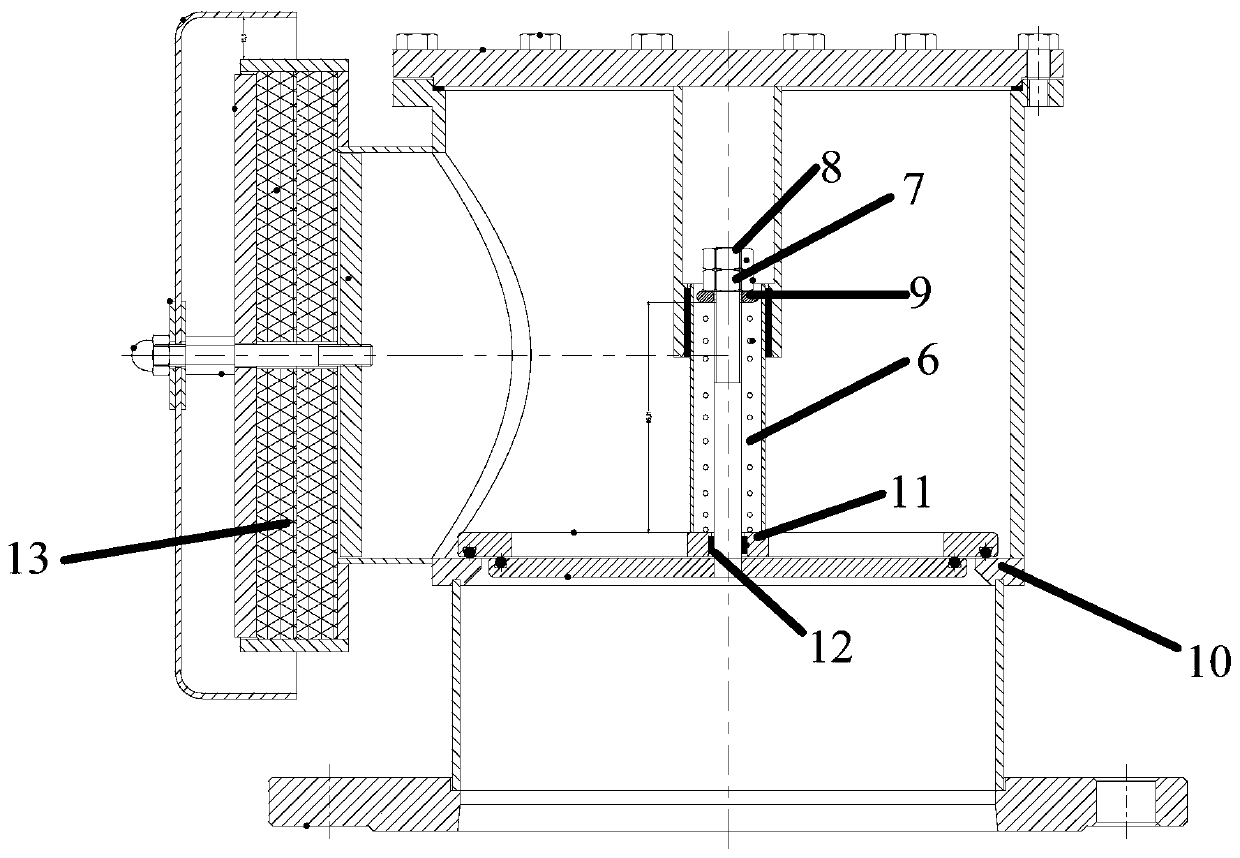

[0032] This embodiment provides a fire-stop breathing valve, such as figure 1 , figure 2As shown, it includes: a valve body 1; a positive pressure valve core 2, which is arranged in the valve body 1, a positive pressure valve tube 3 is arranged on the positive pressure valve core 2, and a ventilating Hole 16; Negative pressure spool 4, set opposite to said positive pressure spool 2, said negative pressure spool 4 is provided with said positive pressure spool 2 and socketed with said positive pressure valve tube 3 The negative pressure valve stem 5; the biasing member 6 is arranged in the positive pressure valve tube 3, the biasing member 6 is socketed with the negative pressure valve stem 5, and one end of the biasing member 6 is connected to the The positive pressure valve core 2 abuts against, and its other end abuts against the limit piece 7 connected with the negative pressure valve stem 5, and the limit piece 7 is driven to move up and down along the length direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com