Patents

Literature

245 results about "Valved tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

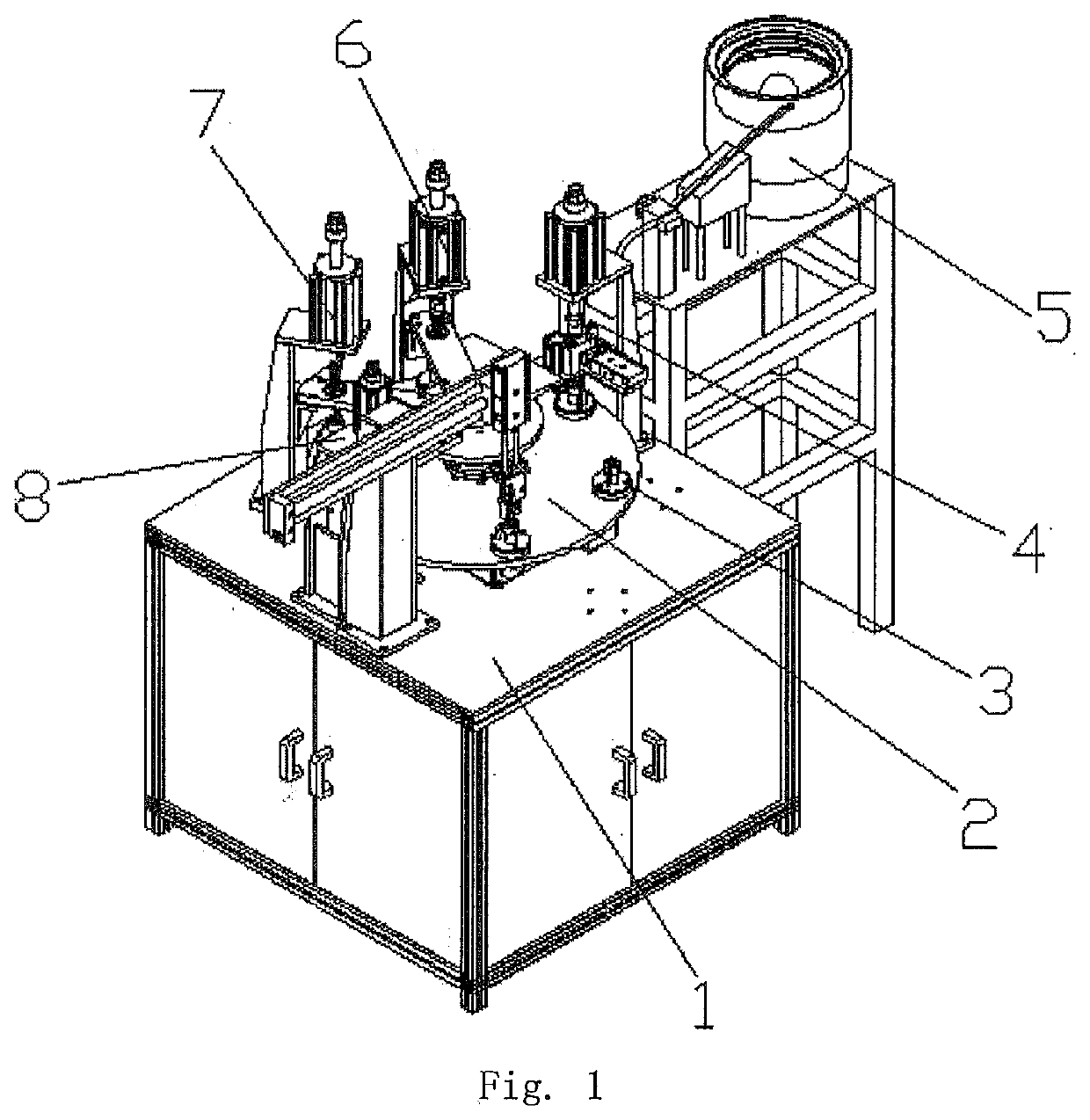

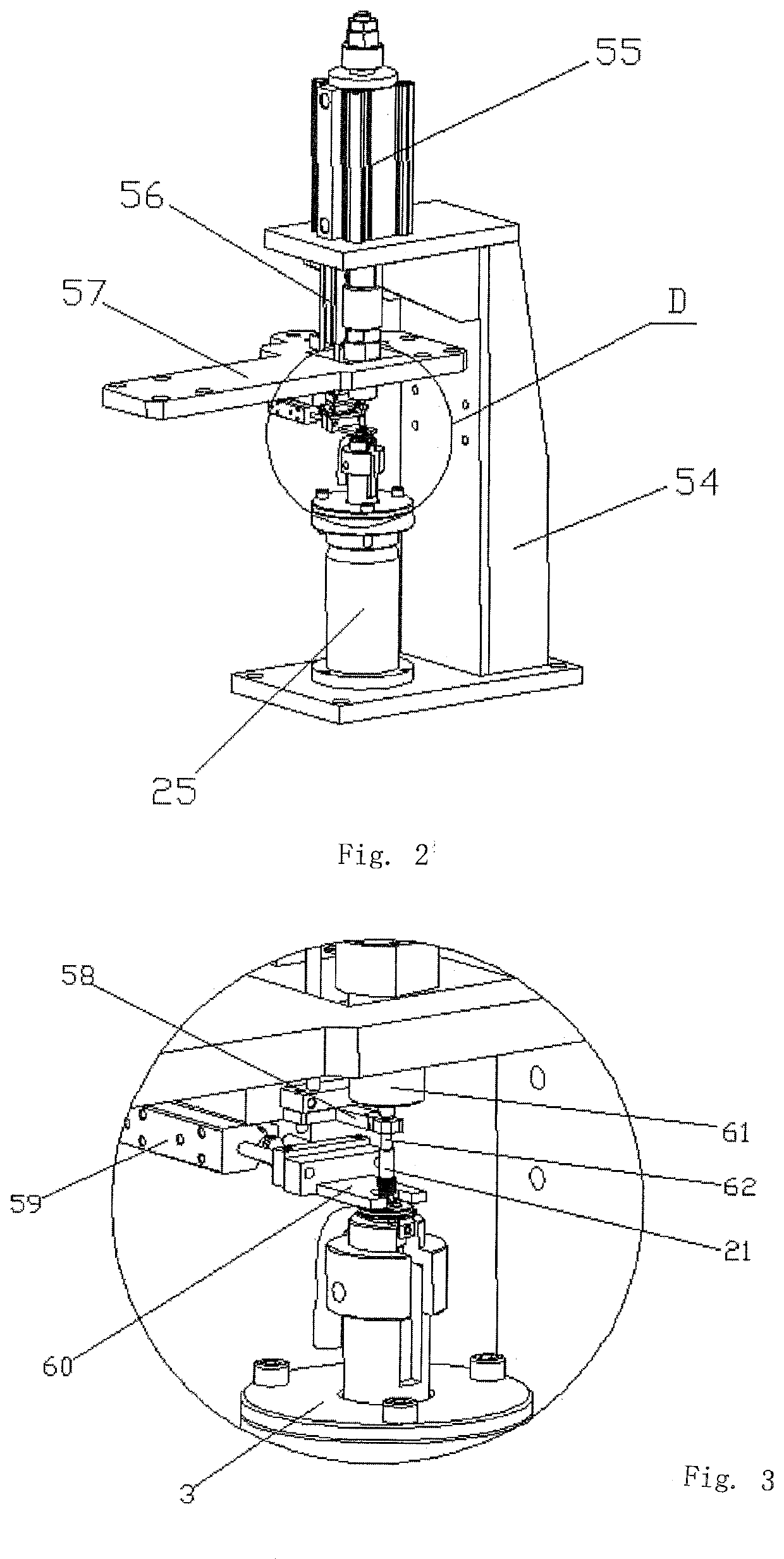

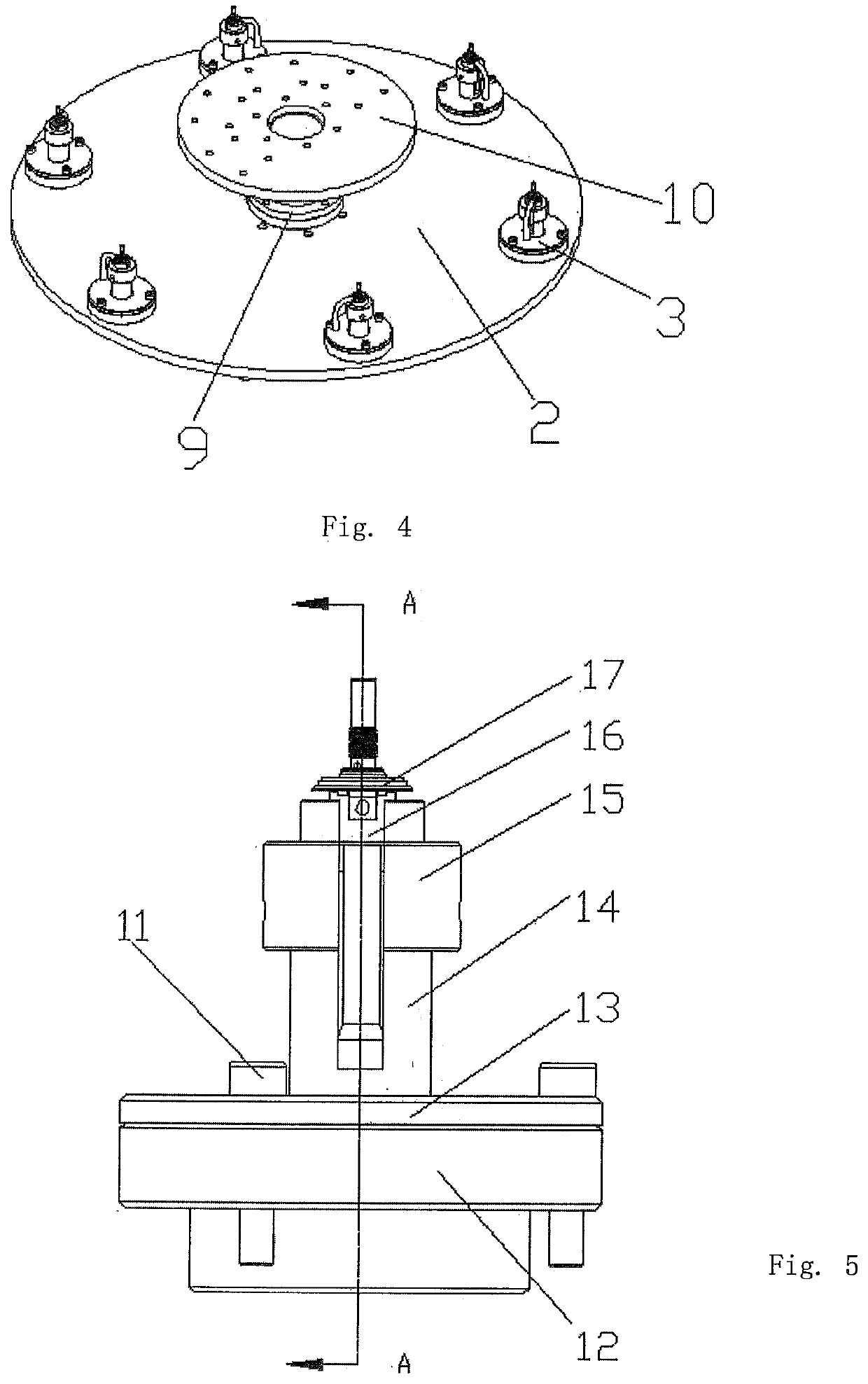

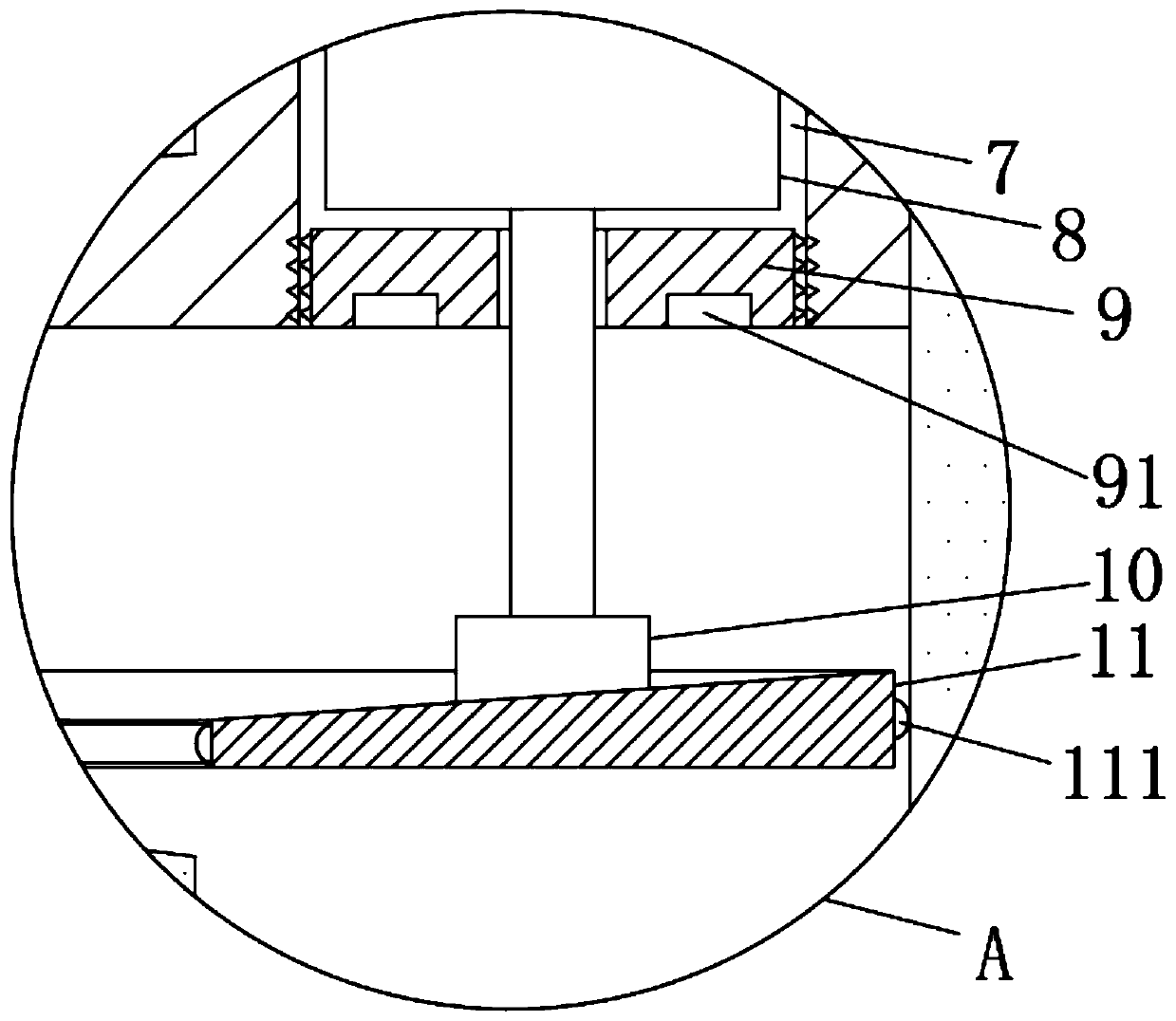

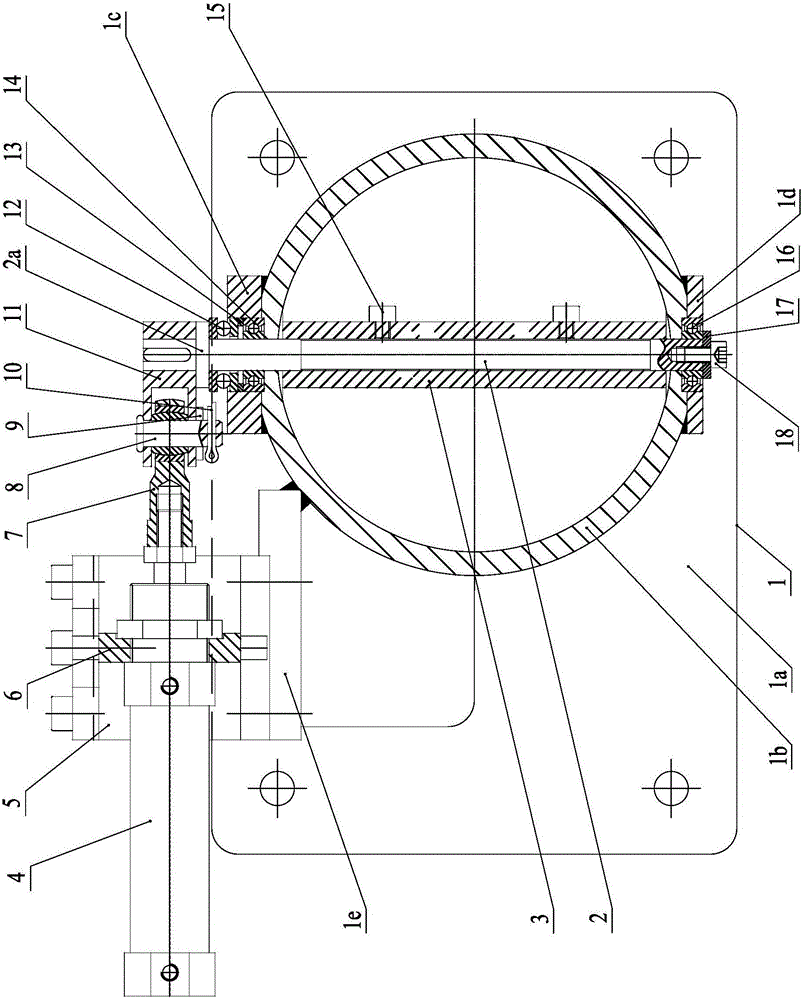

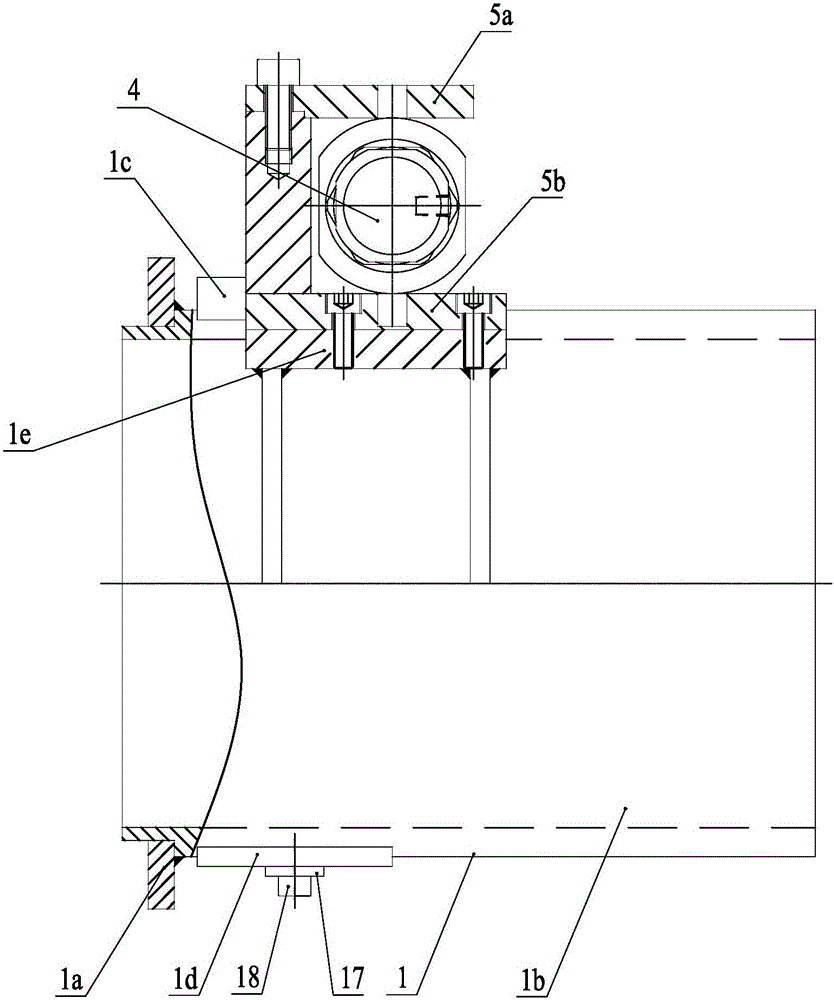

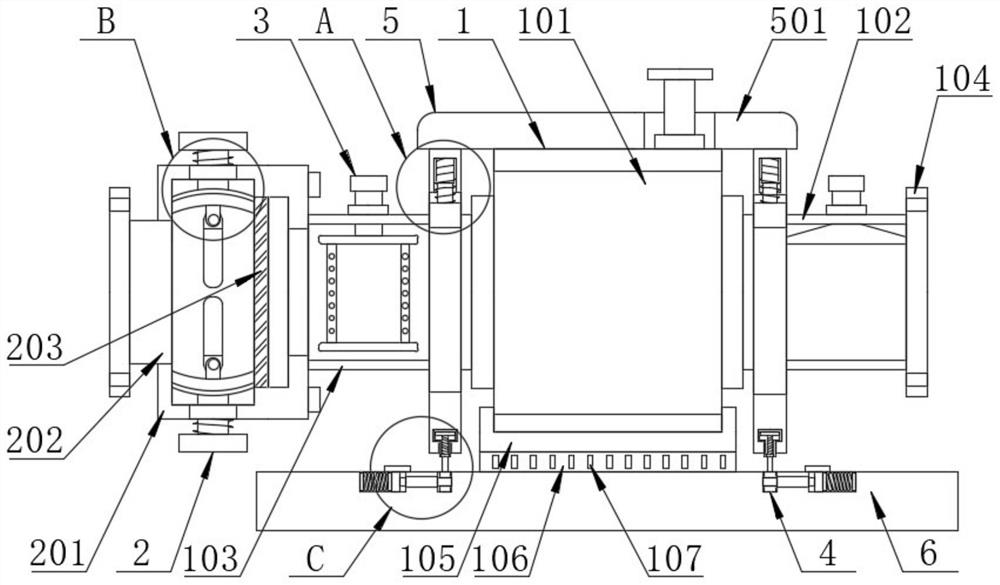

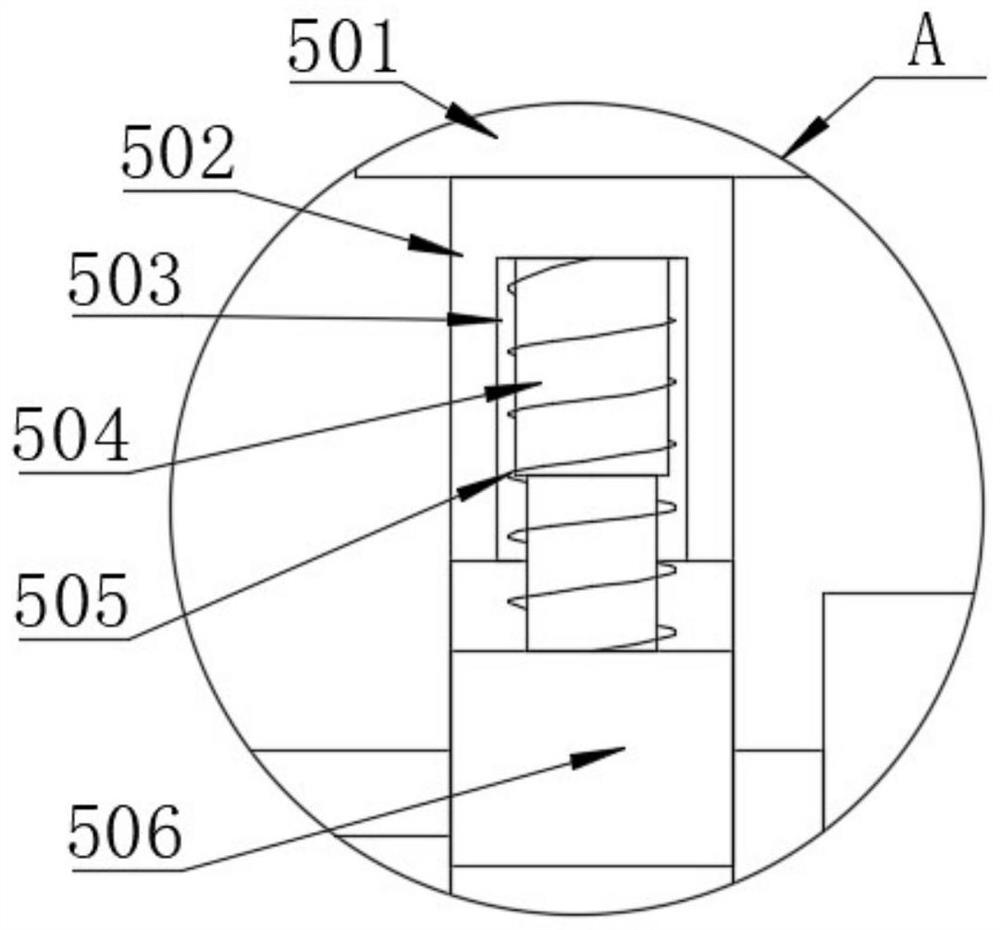

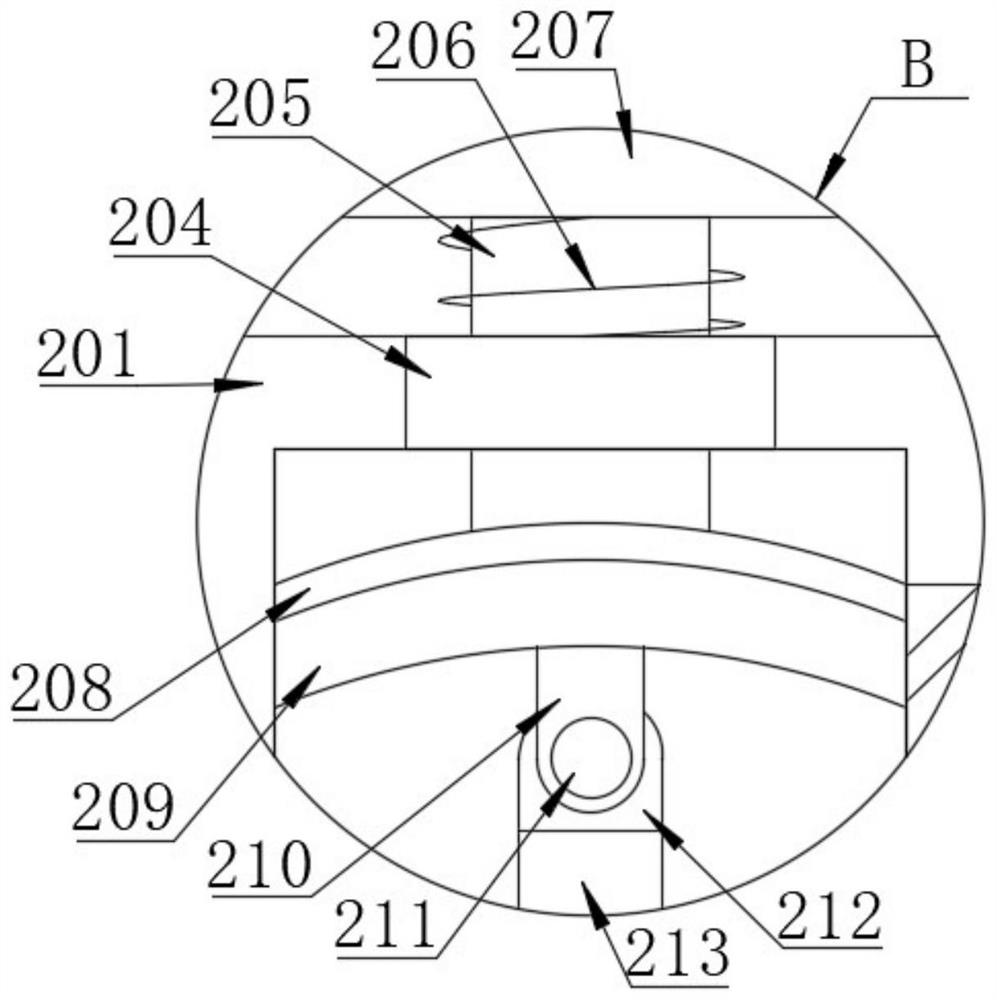

Riveting and grinding assembly for the nozzle of a screw shaft valve

ActiveUS20200038940A1High positioning accuracyEdge grinding machinesAssembly machinesThreaded pipeEngineering

The present invention generally relates to assembly equipment of valve body, especially to riveting and grinding assembly for nozzle of screw shaft valve. The invention may include a rack, a power control box, a turntable and a turntable divider. A carrier assembly which engages with the screw shaft valve body is installed on the edge of the turntable with uniform distribution. On the center part of the turntable, a support shaft which is installed on and fixed with the rack is vertically interposed and on the top of the support shaft, an upper supporting disc is installed. A valve pipe feeding device, a valve pipe preloading device, a valve pipe riveting device and a valve pipe grinding device which engage with the carrier assembly are installed on the said rack on the rotational direction of turntable. As the threaded pipe is put into the carrier assembly by valve pipe feeding device, the carrier assembly rotates counterclockwise along the turntable and rotates to the valve pipe feeding device to the press threaded pipe into the valve seat. Thereafter the carrier assembly rotates the valve pipe riveting device and rivets threaded pipe with a valve flange in order to finish assembling process. Finally, the carrier assembly rotates the valve pipe grinding device to grind nozzle of valve to finish grinding and riveting process of threaded pipe with high positioning accuracy of assembly and marvelous hermetic sealing.

Owner:DONGGUAN UNIV OF TECH

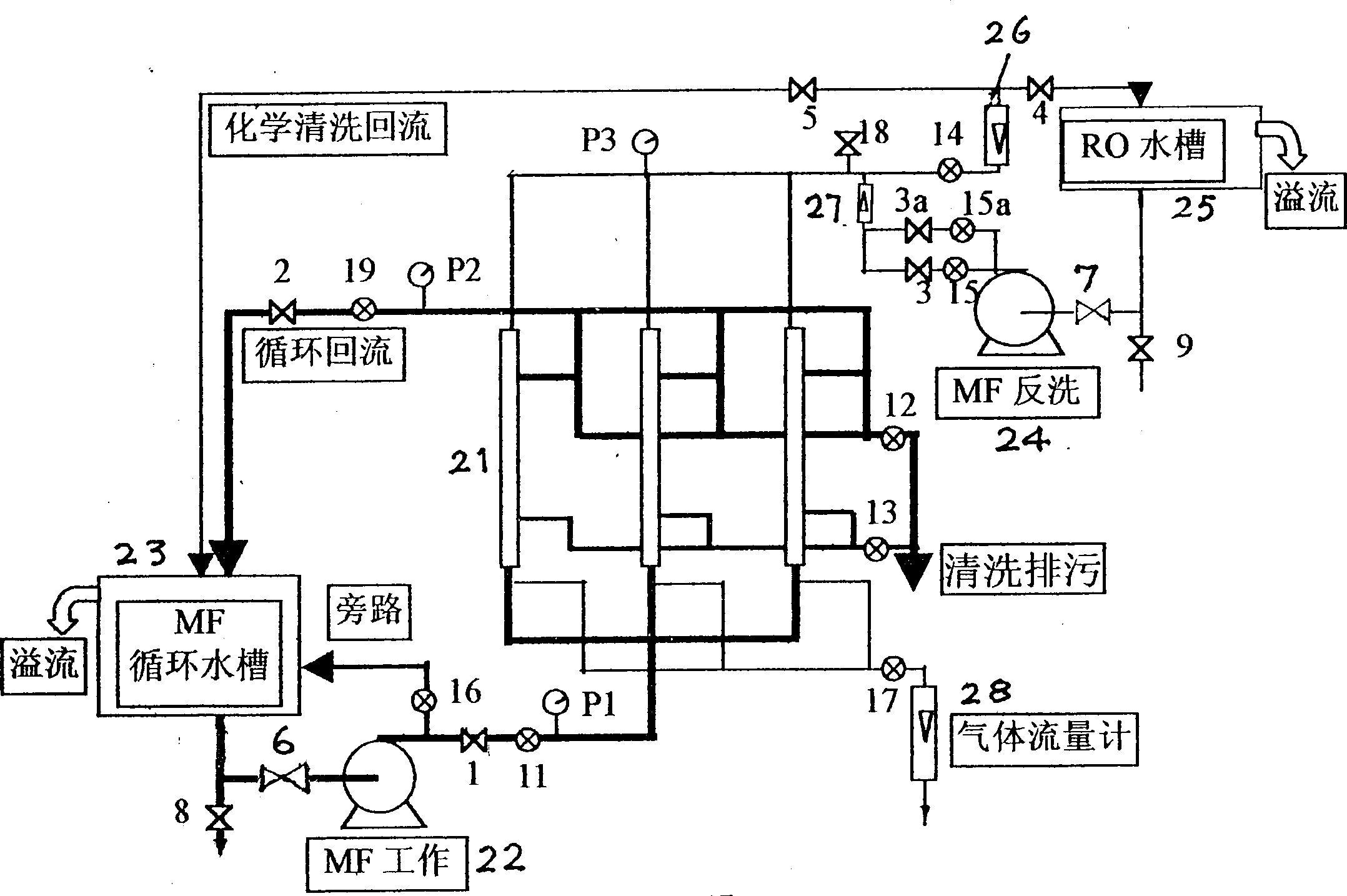

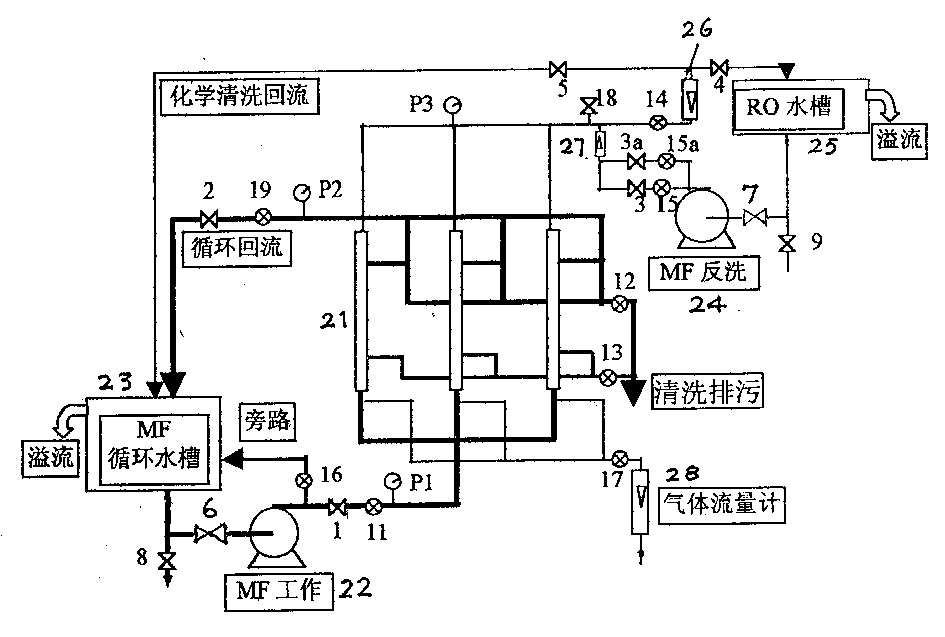

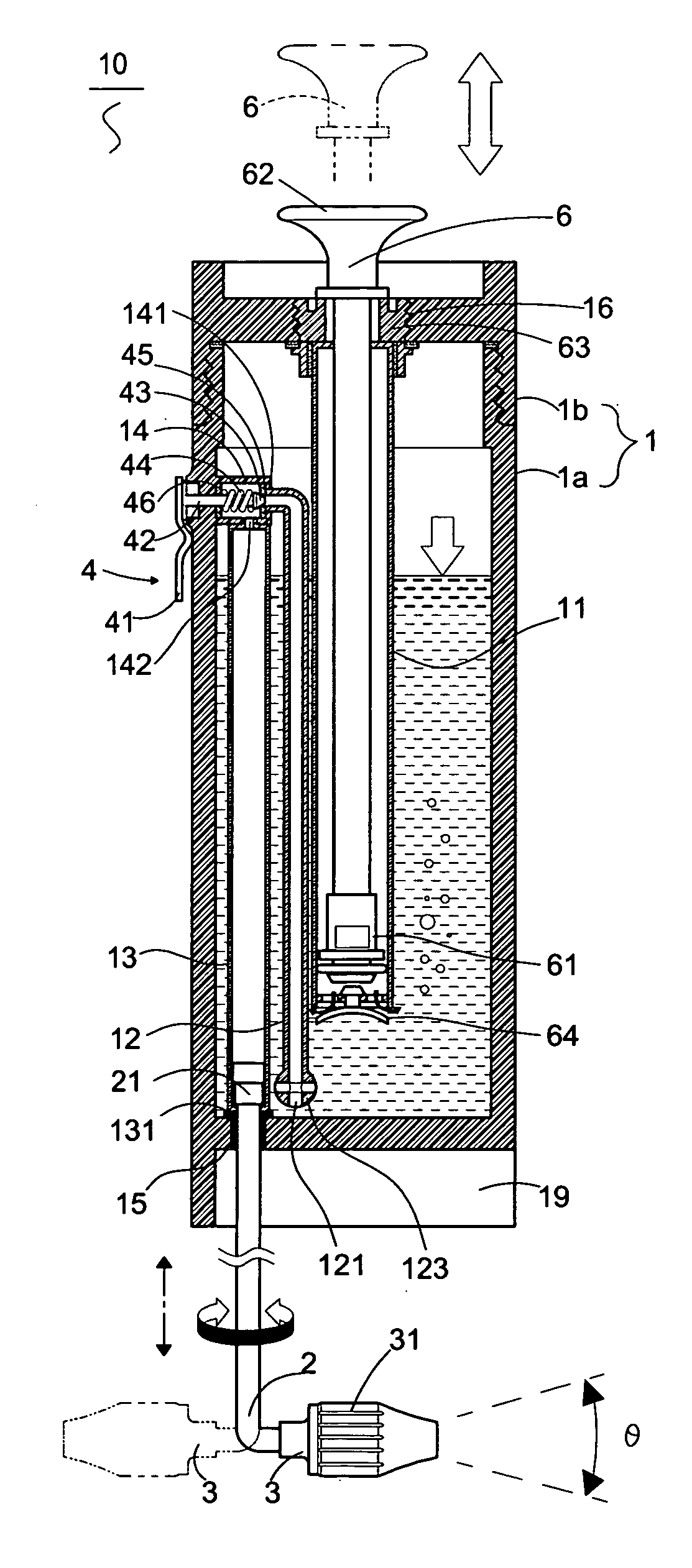

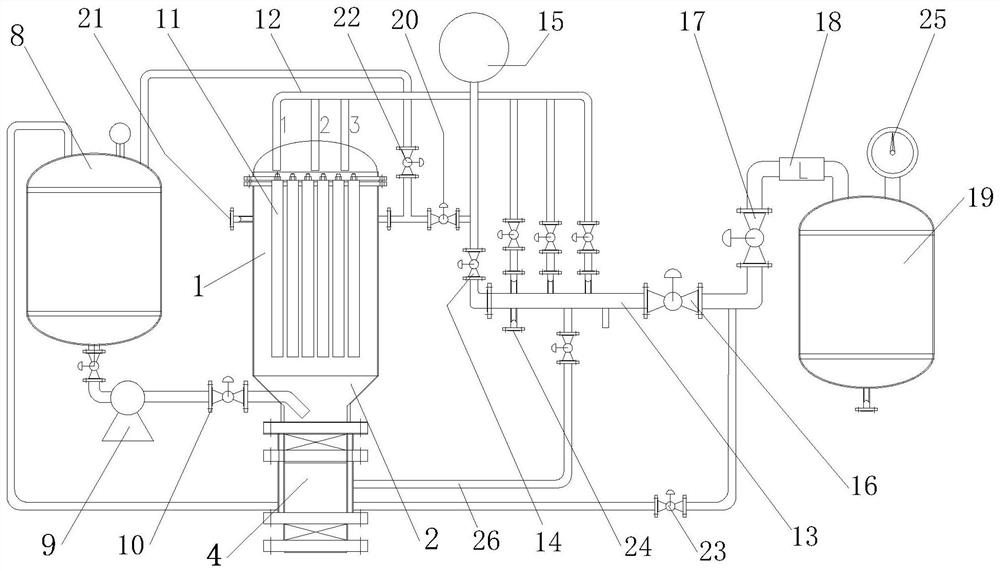

Hollow fiber membrane separator and its running process

InactiveCN1347752AImprove completenessGuaranteed stabilityMembranesUltrafiltrationHollow fibre membraneInlet valve

The hollow fiber membrane separator includes membeane assembly, control valve, pressure gauge, pump, air compressor, water tank, connecting pipes and other parts; and features that the upper mouth ofthe membrane assembly is connected via a back washing flow meter as well as a back washing regulating valve in one channel and a back washing automatic valve to the back washing pump pipe and the back washing pump via its inlet valve is connected to back washing water tank pipe in one channel and discharge valve pipe in the other channel; that the back water tank is connected to the filtering liquid outlet valve pipe via change-over valve and filtering liquid flow meter with the change-over valve being connected to circular water tank. The running process includes two steps in different cleaning states. The present invention makes it possible to realize ideal membrane separation and membrane cleaning.

Owner:TIANJIN MOTIMO MEMBRANE TECH

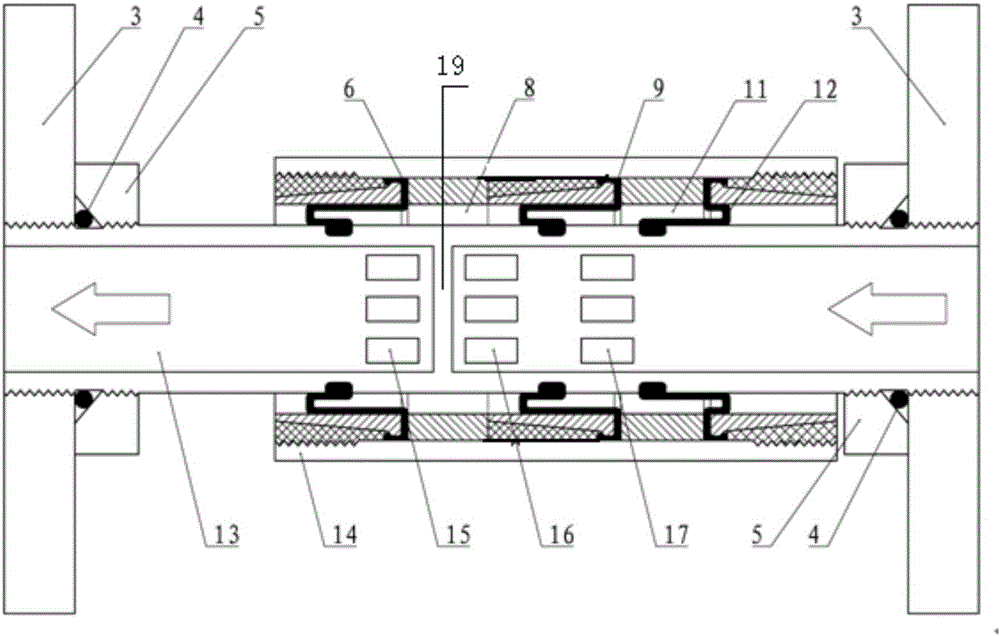

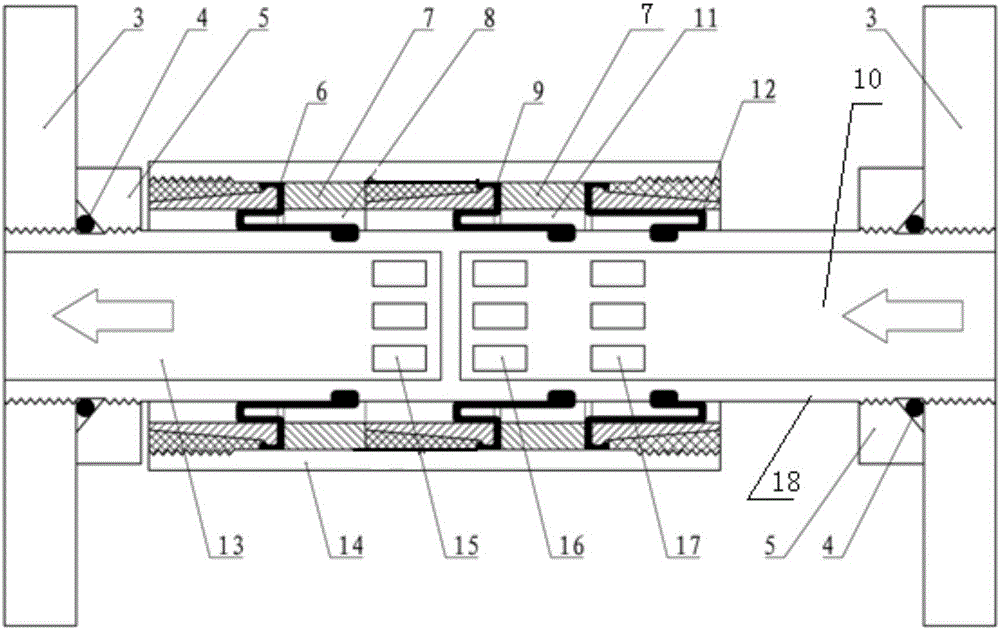

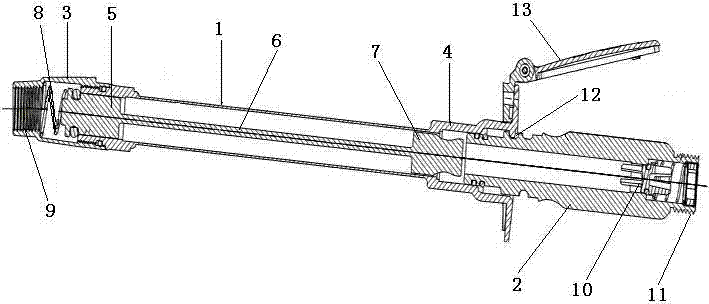

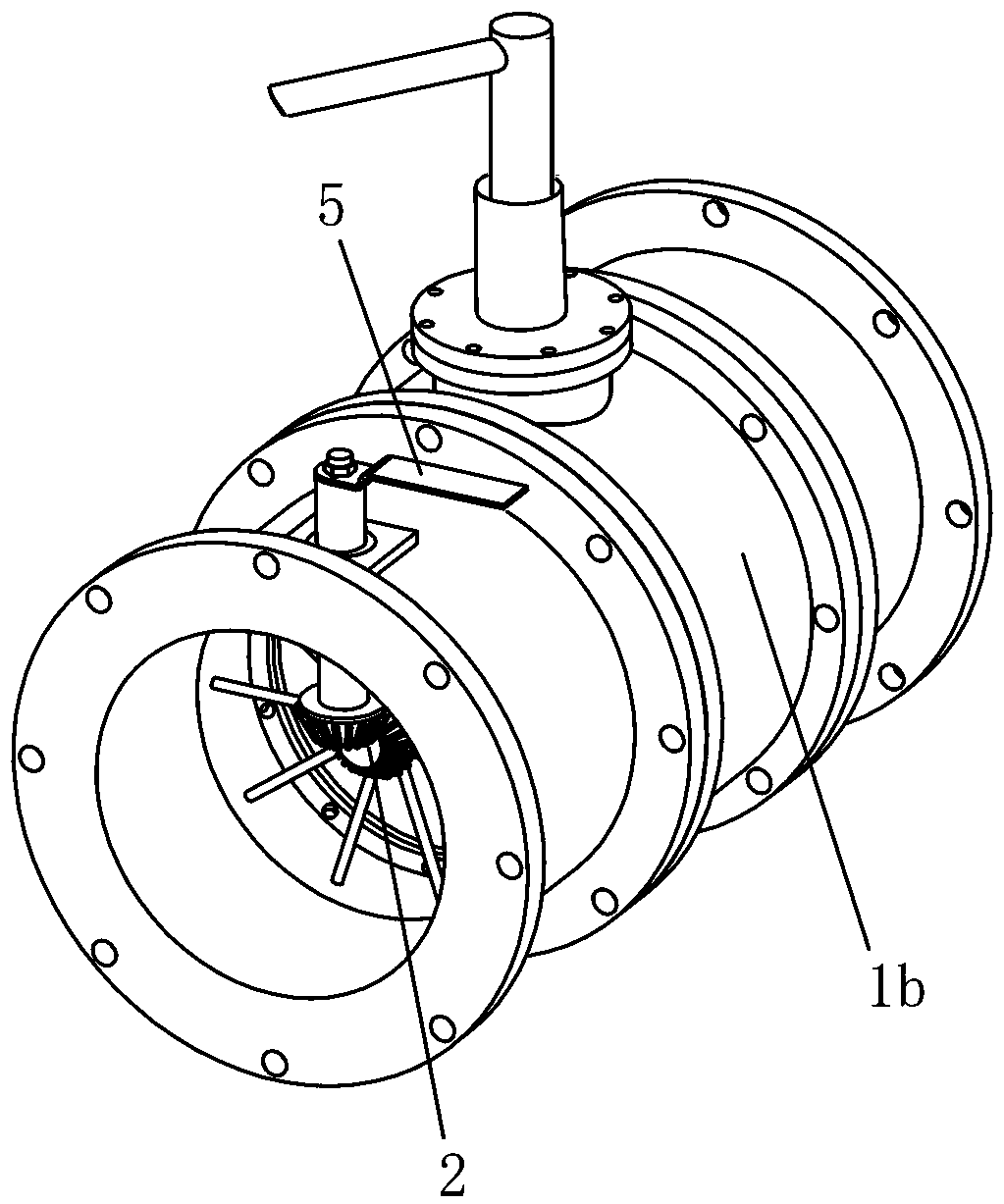

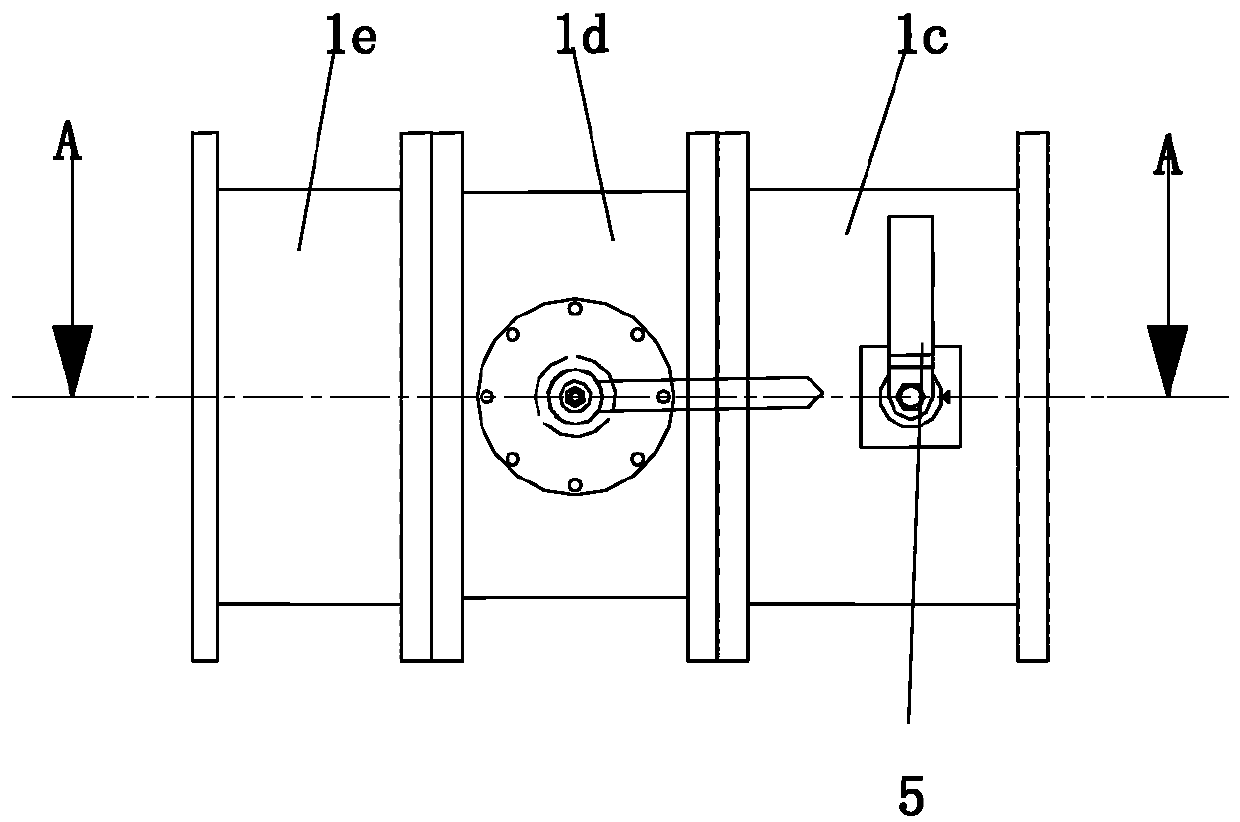

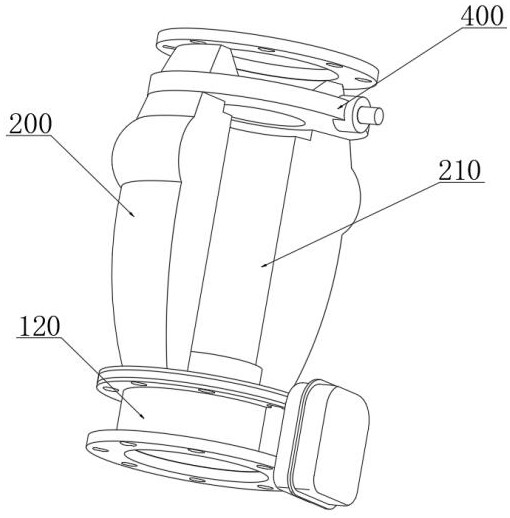

Valve body moving type on-off valve for industrial pipelines

ActiveCN105972238AEliminate uneven quality levelsIncrease resistanceSlide valveThermodynamicsValved tube

The invention relates to a valve body moving type on-off valve for industrial pipelines. The valve body moving type on-off valve is mainly used for solving quality and pollution problems caused by casting machining of present valves. The valve body moving type on-off valve comprises an outer valve pipe and an inner valve pipe. Pipe openings in the two ends of the inner valve pipe serve as an input opening and an output opening respectively and are provided with flanges respectively. The inner valve pipe is provided with a partition, the partition partitions the inner valve pipe into an input section and an output section, the output section is provided with an output valve hole, and the input section is provided with an input valve hole and a balance hole. Three sealing rubber sleeves are arranged between the inner valve pipe and the outer valve pipe, and a water inlet and outlet cavity and a balance water cavity are formed between the sealing rubber sleeves. When the outer valve pipe moves leftwards or rightwards, the valve is switched on or switched off. By the adoption of industrial pipe products, the valve body moving type on-off valve is convenient to machine, reliable in quality and stable in performance, and the problems that casting type valves are not uniform in quality, high in cost and high in pollution are eradicated. The valve body moving type on-off valve is not influenced by the pressure of a fluid medium, is switched on or switched off in a rolling mode, is small in abrasion and on-off flow resistance, large in flow and good in sealing performance and can be used in industrial pipe networks for conveying liquid or gas.

Owner:夏育红

Anti-freezing rapid water taking valve

ActiveCN104728455APrevent freezingPrevent civil misappropriationOperating means/releasing devices for valvesLift valveAnti freezingEngineering

The invention provides an anti-freezing rapid water taking valve. The anti-freezing rapid water taking valve is composed of a water taking valve body and a water taking valve handle. The water taking valve body is composed of a valve pipe, an upper valve main body, a lower valve main body and a piston. The length of the valve pipe can be designed according to parameter requirements of a cold-proof heat preservation body. The upper valve main body is connected to the upper end of the valve pipe and provided with a water supply connecting end. When the water supply connecting end is installed, it is guaranteed that the central axis of the water taking valve body and the horizontal plane form an included angle of 5 degrees. The lower valve main body is connected to the lower end of the valve pipe and comprises a water taking valve handle connecting clamp and a windproof dustproof cover. The piston is composed of an upper piston body, a connecting rod, a lower piston rod body and a reset spring, wherein the upper piston body and the lower piston body are installed in inner cavities of the upper valve main body and the lower valve main body respectively, the connecting rod is in the valve pipe and connects the upper piston body and the lower piston body, and the reset spring is arranged between the water supply connecting end and the upper piston body. The water taking valve handle is rapidly connected with the water taking valve body through a comma-shaped clamping groove in the water taking valve handle, and then water supply is achieved.

Owner:SHUANGYING ZHANGZHOU PRECISION METAL PROD CO LTD

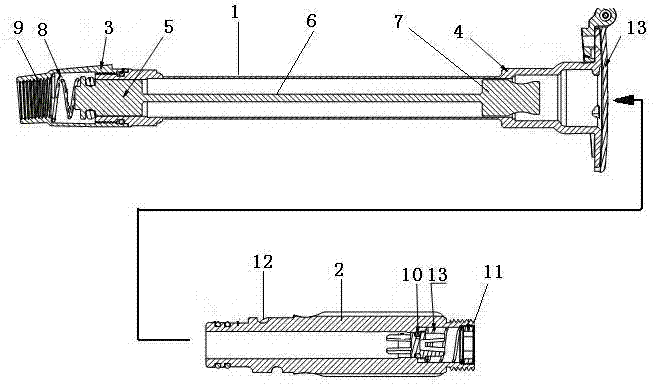

Portable pneumatic washing device

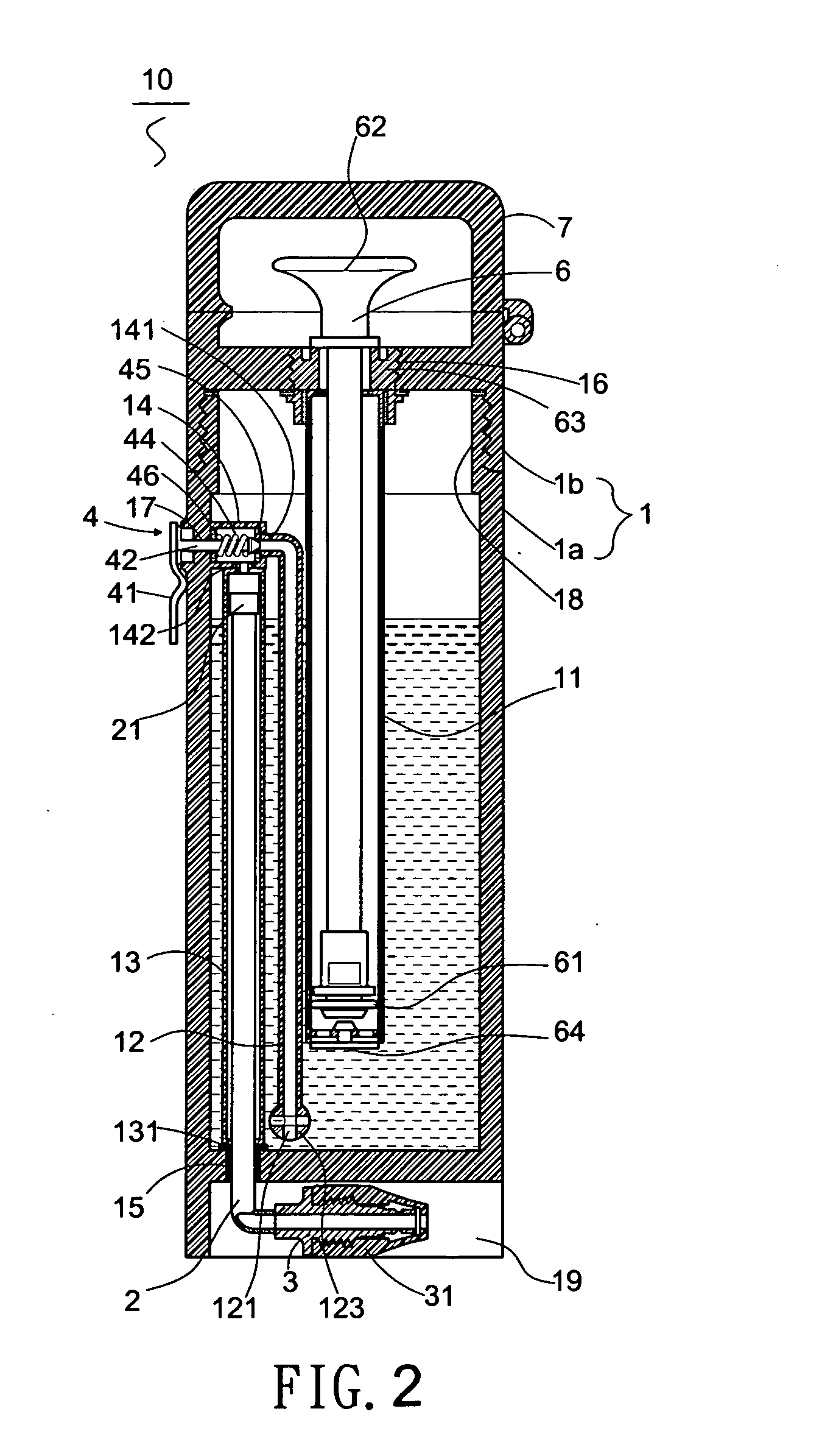

Portable pneumatic washing device 10 having a body 1 consists of three axially arrayed pipes 11˜13, a transversal valve pipe 14. Pipe 11 impelled by a push rod 6 to pump air into body 1. Distal ends of pipes 12,13 connected to inlet, outlet orifices of the valve pipe 14 respectively. But a proximal end of the pipe 13 securely connected to a hole 15 at a proximal end of the body 1. A control valve 4 installed outside the sidewall of the body 1 switches on / off the inlet orifice 141 of the valve pipe 14. When the inlet orifice 141 open, a liquid retained in the body 1 flows through pipe 12, valve pipe 14 into a telescopic spray pipe 2 of the pipe 13 to spill liquid from the spray head 3 at a distal end of the spray pipe 2 outside the hole 15.

Owner:LAI SHIN BING

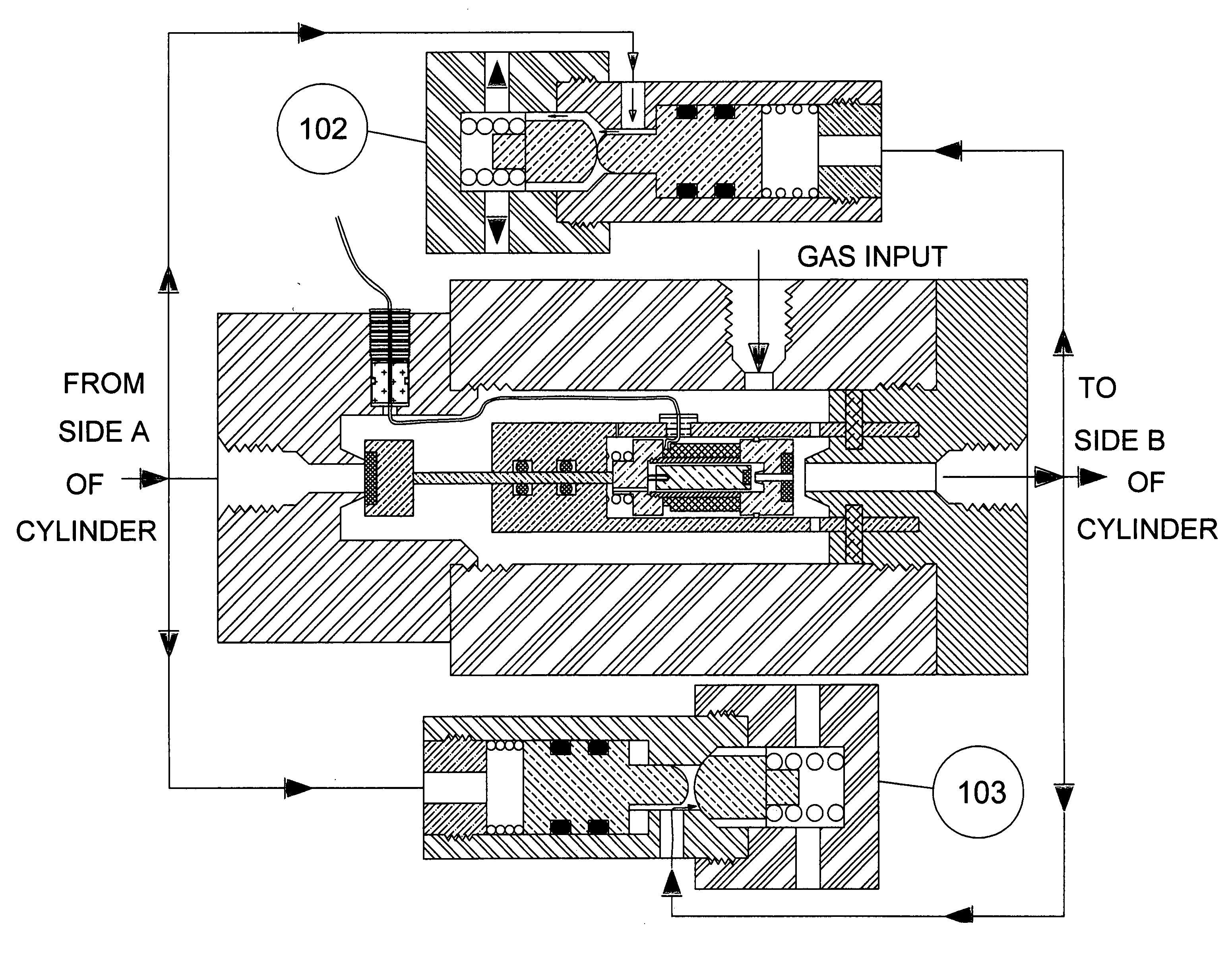

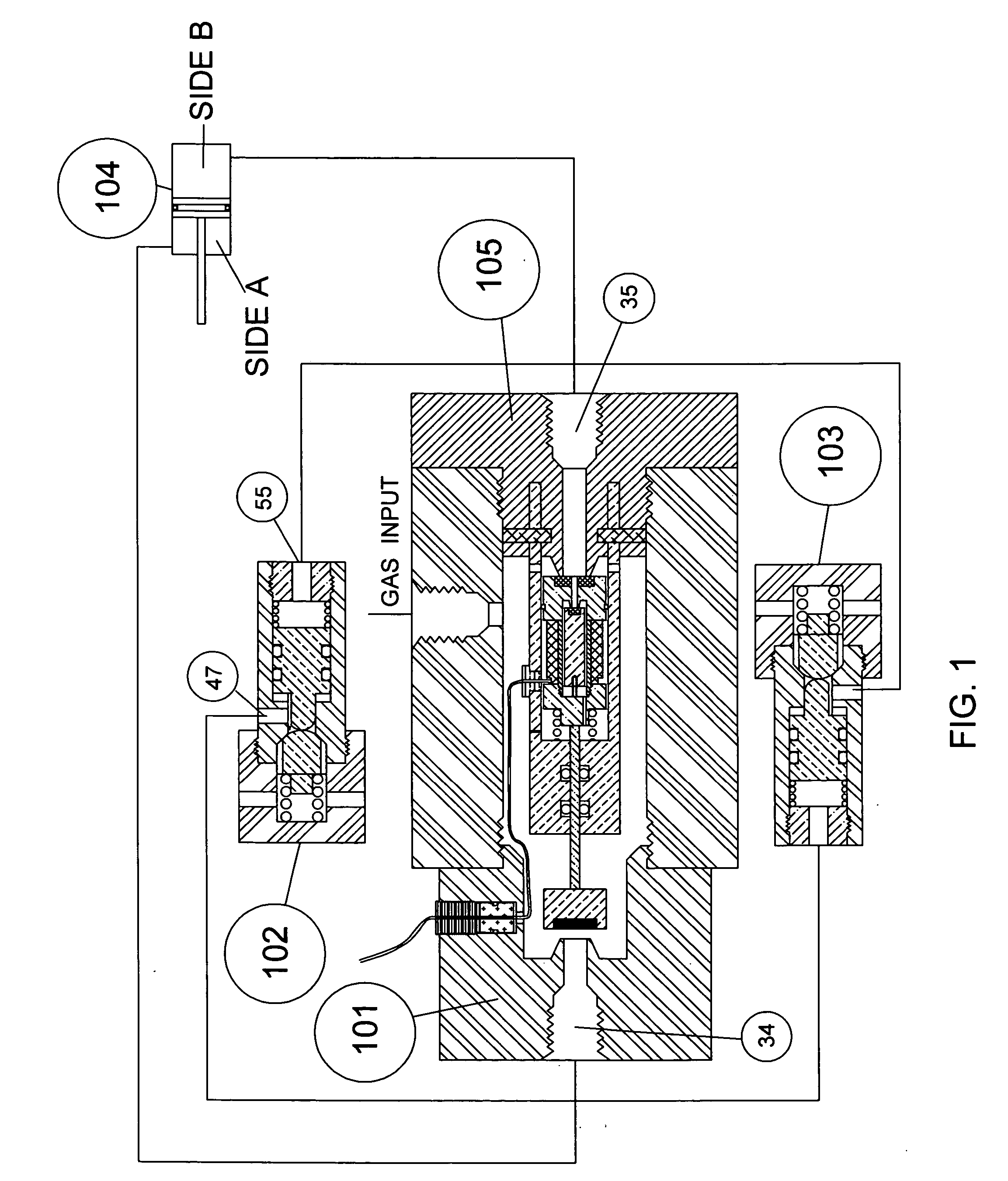

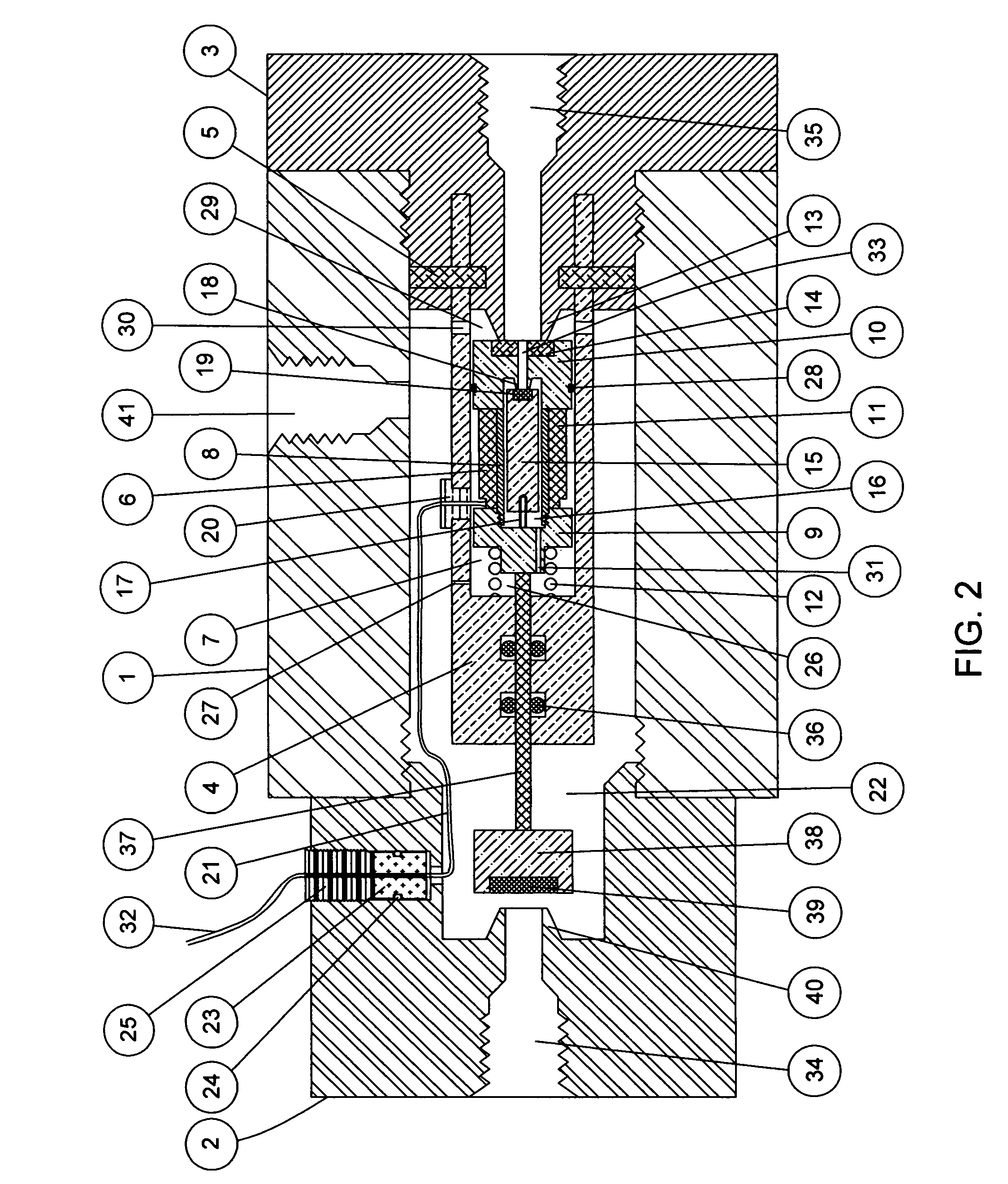

Three-way, two-position in-tube solenoid gas valve assembly

InactiveUS20070175529A1Avoid disadvantagesPromote escapeFluid-pressure actuator safetyOperating means/releasing devices for valvesSolenoid valveEngineering

A new three-way, two-position in-tube solenoid gas valve assembly comprises a modified in-tube solenoid gas valve and a pair of gas release valves is designed to control pneumatic systems. The modified in-tube solenoid gas valve is a modification based on the previous invention by Wang et al., U.S. Ser. No. 10 / 924,789. The new modifications are first adding a rod-piston assembly onto the solenoid assembly, a new inlet was added to the valve tube and two outlet fittings were also added. With these modifications, the systems can now work with two directions of gas flows, which is important to control pneumatic systems. To be able to control pneumatic systems properly, two gas release valves are included as part of the assembly. The goal of these two gas release valves is to be able to release gas from pneumatic quickly and completely. These gas release valves are operated based on two compression springs and through gas inputs into the valves. The operations of the gas releases valves are simultaneously while one opens the other closes. The opening and the closing of the gas release valve depends on the state of the modified solenoid gas valve.

Owner:WANG WEI CHING +2

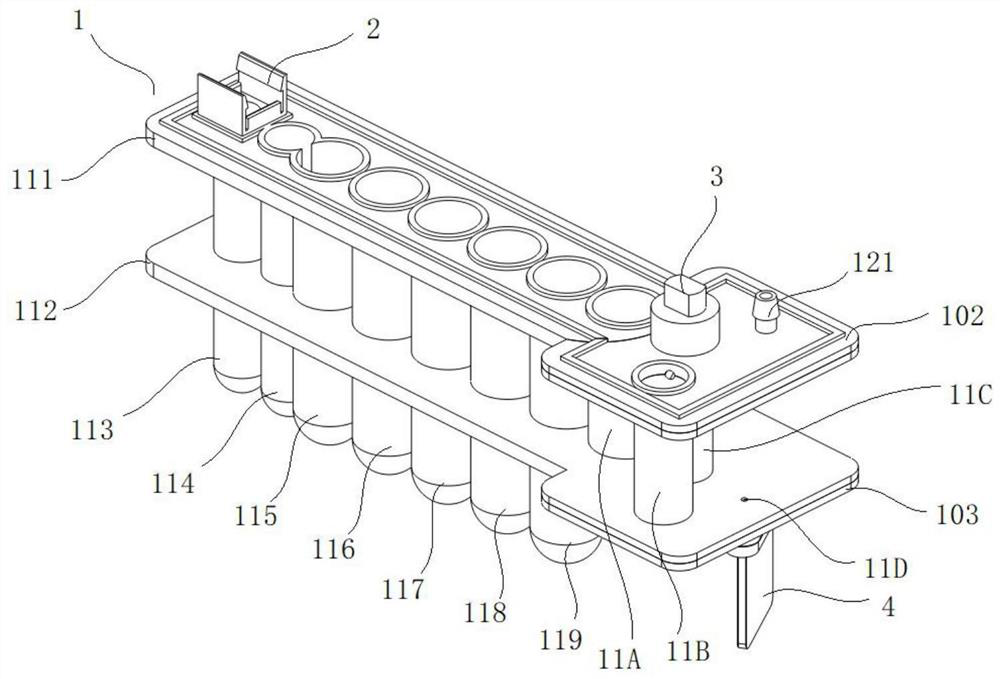

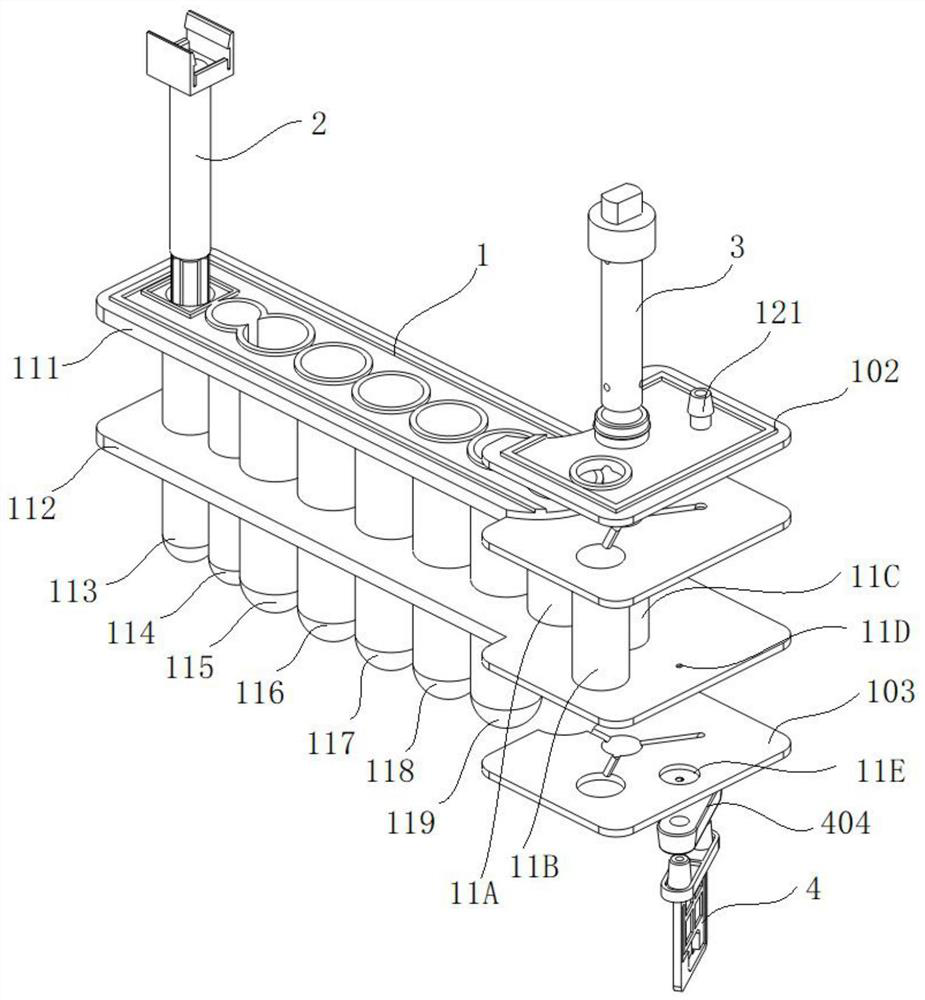

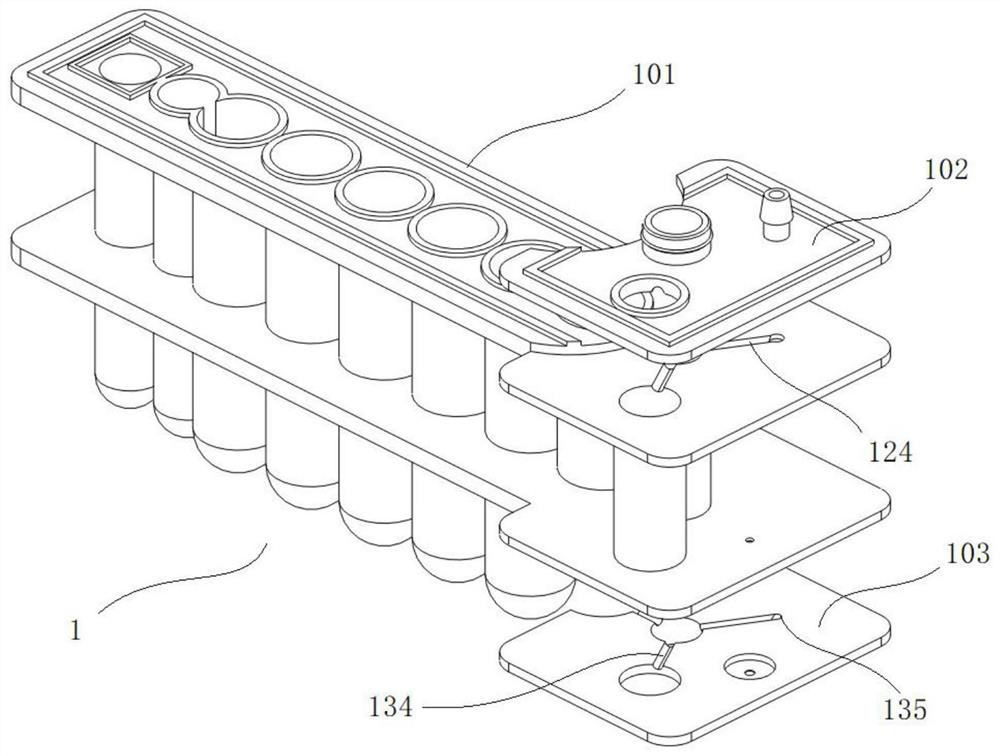

Nucleic acid detection cassette based on magnetic bead transfer and valve controlled pipetting and detection method thereof

ActiveCN112226361ASimple structureTest applicableBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid detectionThroat swab

The invention discloses a nucleic acid detection cassette based on magnetic bead transfer and valve controlled pipetting and a detection method thereof, a cassette body is divided into a nucleic acidextraction area and an amplification detection area, the amplification detection area is provided with a rotary valve tube, a PCR tube, a gas pump interface, a gas channel and a liquid channel, the gas channel respectively extends from the rotary valve tube to a liquid mixing tube and the gas pump interface. The liquid channel respectively extends from the rotary valve tube to a elution tube, theliquid mixing tube and the PCR tube; and a rotary valve for controlling the opening and closing of the gas channel and the liquid channel is arranged in the rotary valve tube. According to the presentinvention, the clinical collection throat swab without any treatment can be directly added, the nucleic acid extraction is achieved by externally driving a magnetic rod and a magnetic rod sleeve, theopening and the closing of the related liquid channel and the gas channel are achieved by controlling the rotary valve, the directional transfer of the liquid can be achieved under the effect of theexternal pump, and finally the real-time fluorescence PCR amplification detection is performed in the PCR tube, so that sample input and result output can be simply and efficiently realized.

Owner:SOUTHEAST UNIV

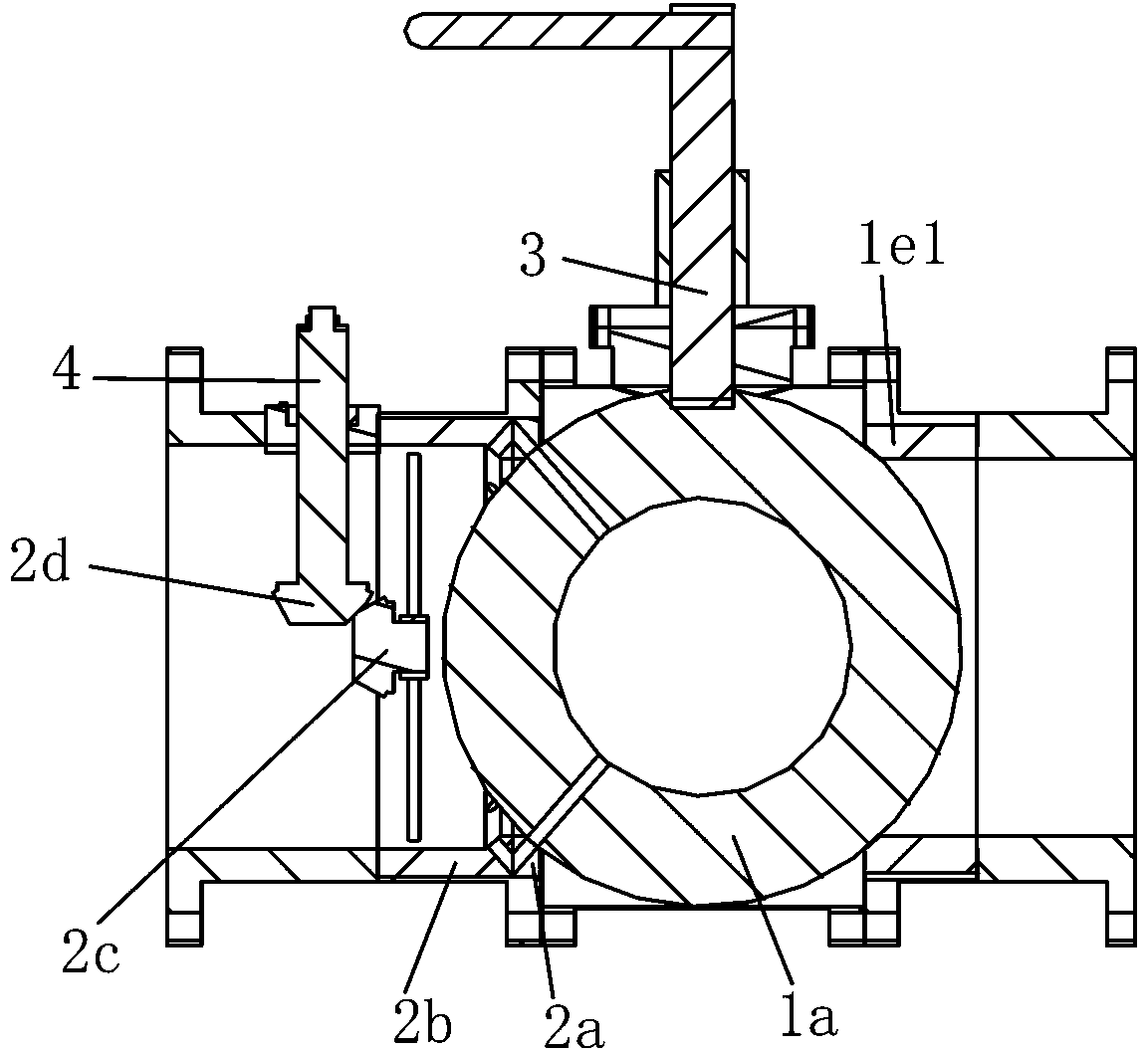

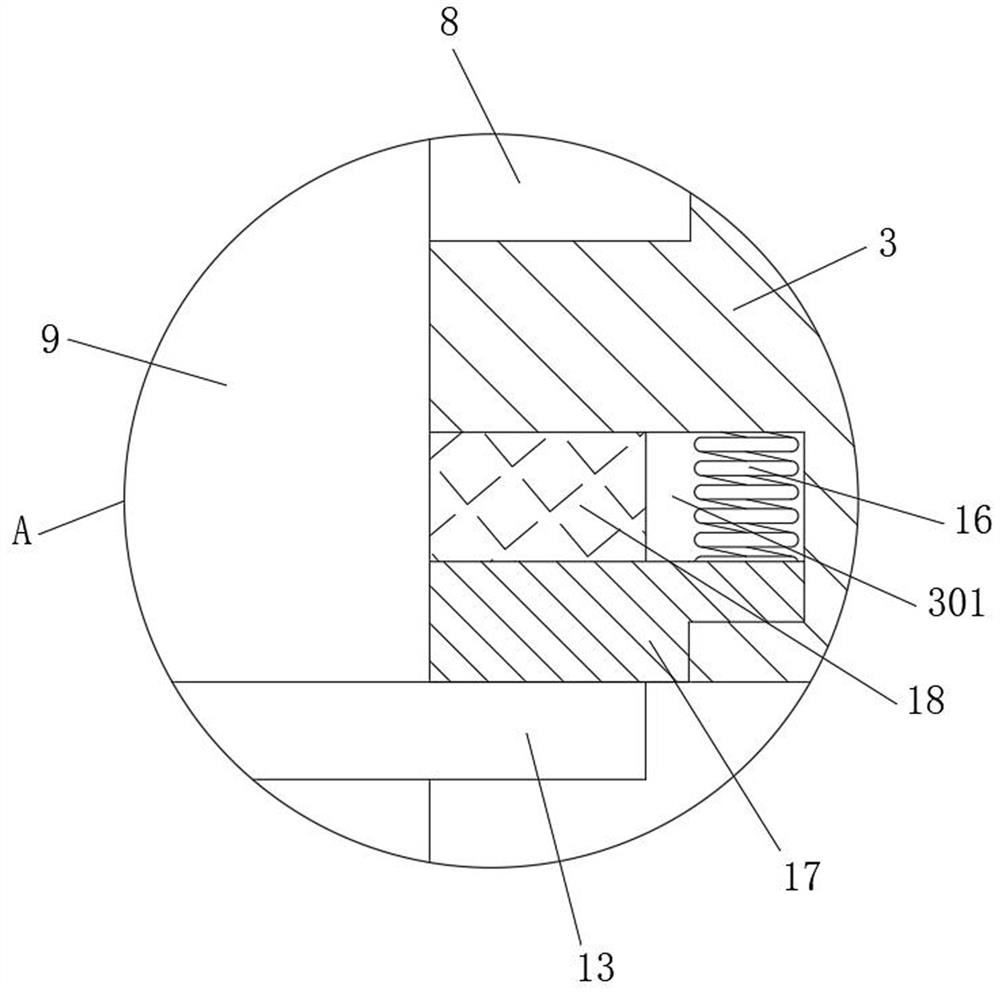

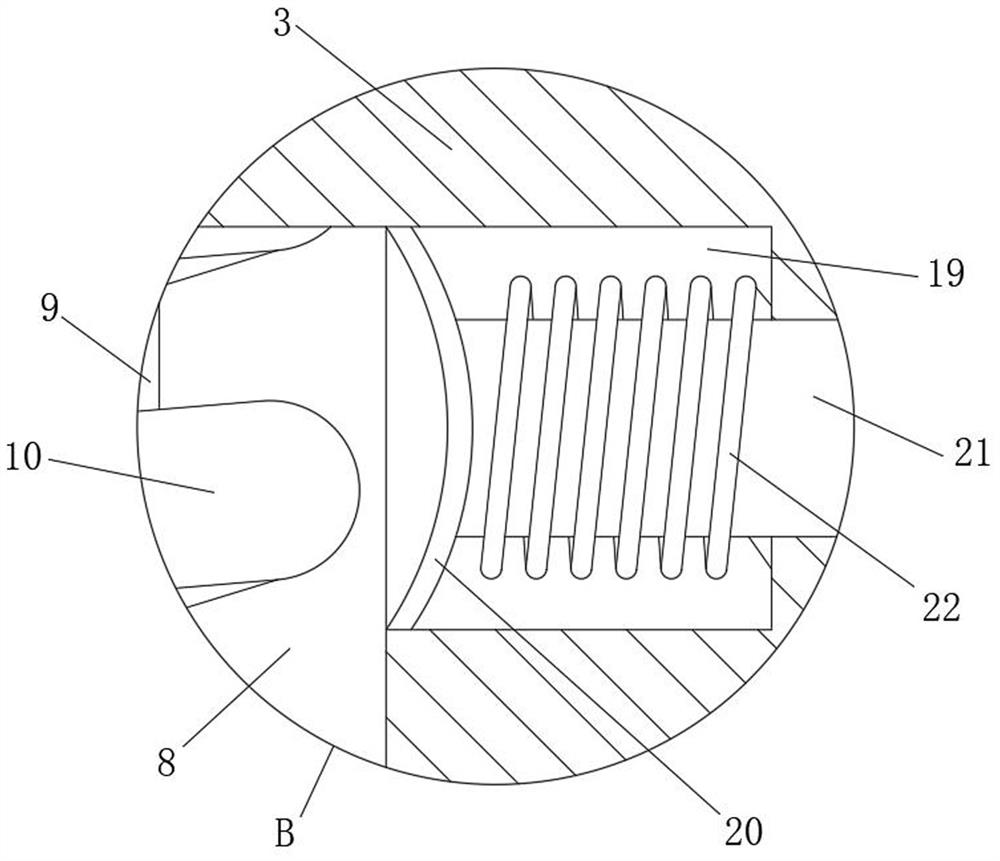

High-pressure hydraulic ball valve easy to open

PendingCN107830194AEasy to openReduce pressurePlug valvesOperating means/releasing devices for valvesEngineeringHigh pressure

The invention relates to the field of control valves, in particular to a high-pressure hydraulic ball valve easy to open. The high-pressure hydraulic ball valve easy to open comprises a ball valve anda pressure pre-relieving mechanism; the ball valve comprises a valve body, and a ball body arranged in the valve body; the valve body comprises a first valve pipe for accommodating the pressure pre-relieving mechanism, a second valve pipe for accommodating the ball body, and a third valve pipe; two ends of the second valve pipe communicate with the first valve pipe and the third valve pipe; axesof the first valve pipe, the second valve pipe and the third valve pipe are overlapped; the pressure pre-relieving mechanism comprises a valve base, and a transmission mechanism matched with the valvebase; the valve base is annular; the valve base is provided with multiple first through holes distributed in the peripheral direction of the valve base by equal angle differences; and the transmission mechanism comprises an adjusting piece for adjusting connection and disconnection of all the through holes, and a driving module for driving the adjusting piece to rotate along the axis of the valvebase. When the ball valve is needed to convert from a closing state to a conducting state, the pressure pre-relieving mechanism reduces the pressure in the ball valve beforehand, and the torque needed by opening is reduced, so that workers are convenient to open the ball valve.

Owner:NINGBO TIANXIANG XINHUA HYDRAULIC CO LTD

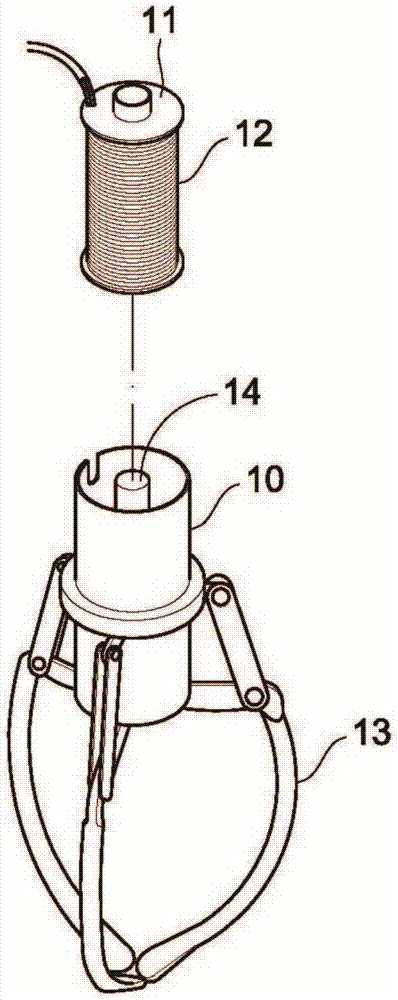

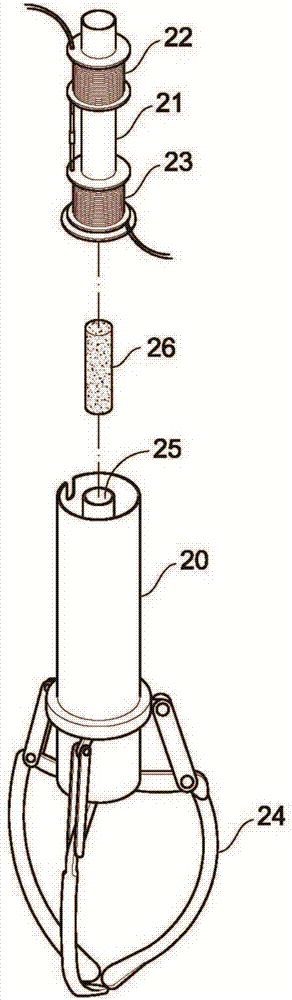

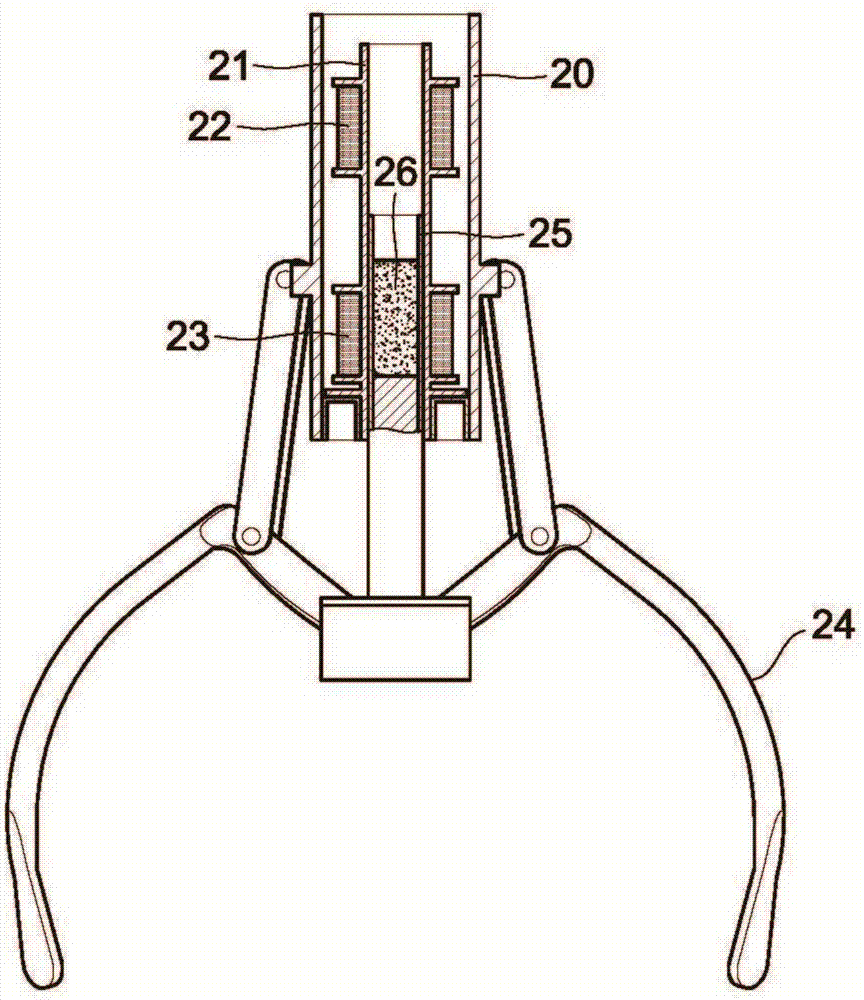

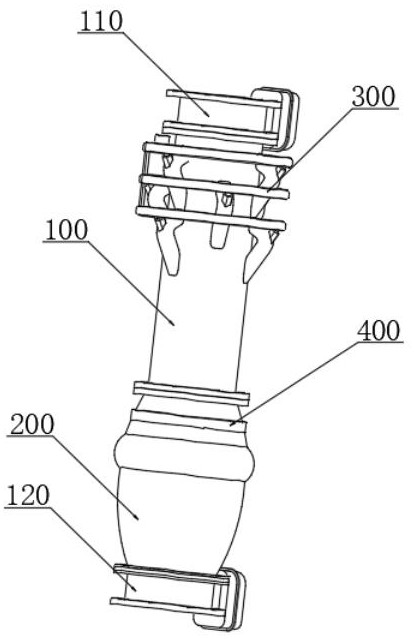

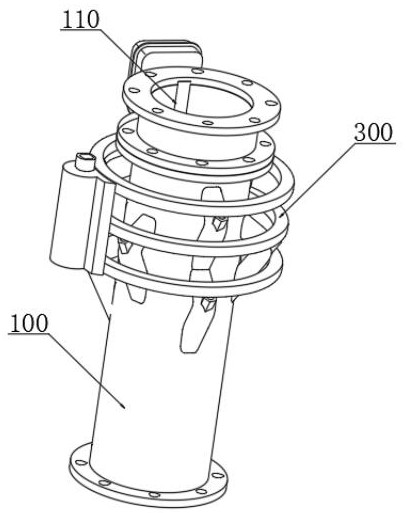

Gripper structure

The invention discloses a gripper structure. The gripper structure comprises a body, a valve pipe, a clamping jaw and a vertical pipe, the valve pipe is arranged in the body, and the vertical pipe is pivoted to the clamping jaw which is pivoted to the bottom of the body. When the vertical pipe moves up and down, the clamping jaw is contracted inwards or expanded outwards, upper and lower ends of the valve pipe are wound by an upper coil section and a lower coil section respectively, the tail end of the upper coil section is connected with a starting end of the lower coil section, and a starting end of the upper coil section and the tail end of the lower coil section are connected with an external power source. The gripper structure further comprises a magnetic element which is arranged in the valve pipe in a vertically movable manner, and the magnetic element is connected with the vertical pipe. A magnetic pole at the top end of the magnetic element is opposite to that above the electrified upper coil section, a magnetic pole at the bottom end of the magnetic element is opposite to that above the electrified lower coil section, and the length of the magnetic element corresponds to a distance between the upper coil section and the lower coil section.

Owner:谢代英

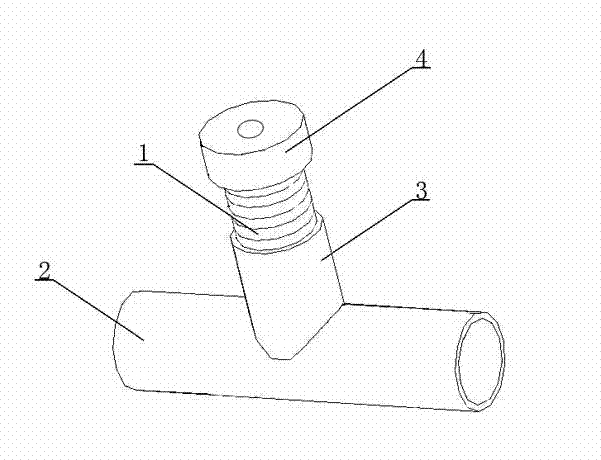

Thoracic closed drainage three-way connecting tube

The invention relates to a thoracic closed drainage three-way connecting tube, which comprises a three-way tube and a screw-in one-way tube, wherein the three-way tube comprises a drainage tube and a valve tube which are perpendicular to each other; two ends of the drainage tube are respectively connected with a thoracic cavity and a chest bottle; the screw-in one-way tube is in threaded connection in the valve tube; one end of the screw-in one-way tube extending out of the valve tube is provided with a positive pressure injection cap; and a medicine guide tube is arranged in the screw-in one-way tube and is communicated with a medicine injection port of the positive pressure injection cap and a medicine outlet on the side wall of the bottom of the screw-in one-way tube. The thoracic closed drainage three-way connecting tube is simple in structure, can conveniently and quickly control the drainage of a thoracic cavity drainage tube and thoracic infusion treatment, eliminates potential safety hazards to the patient and avoids unnecessary injury.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

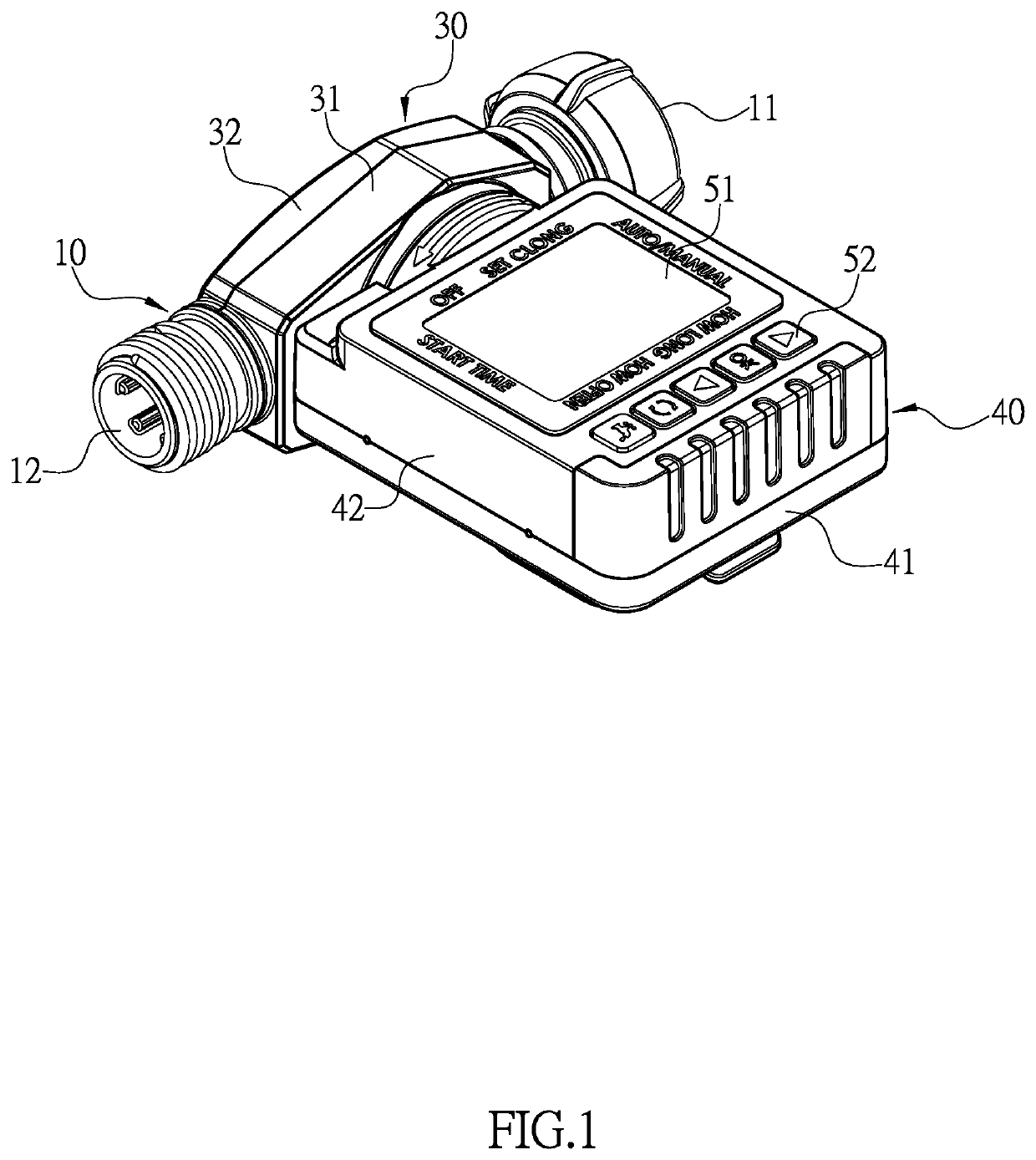

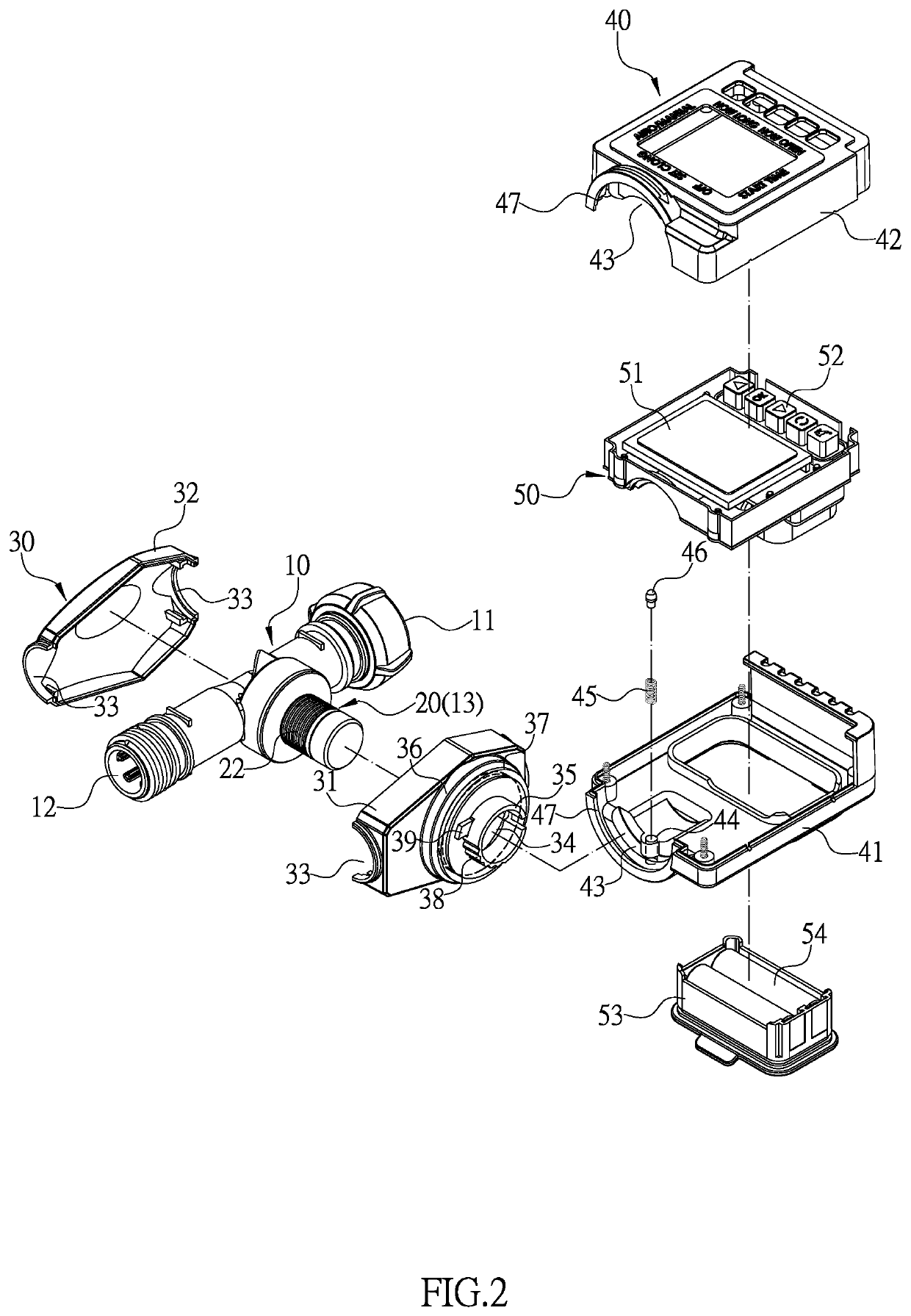

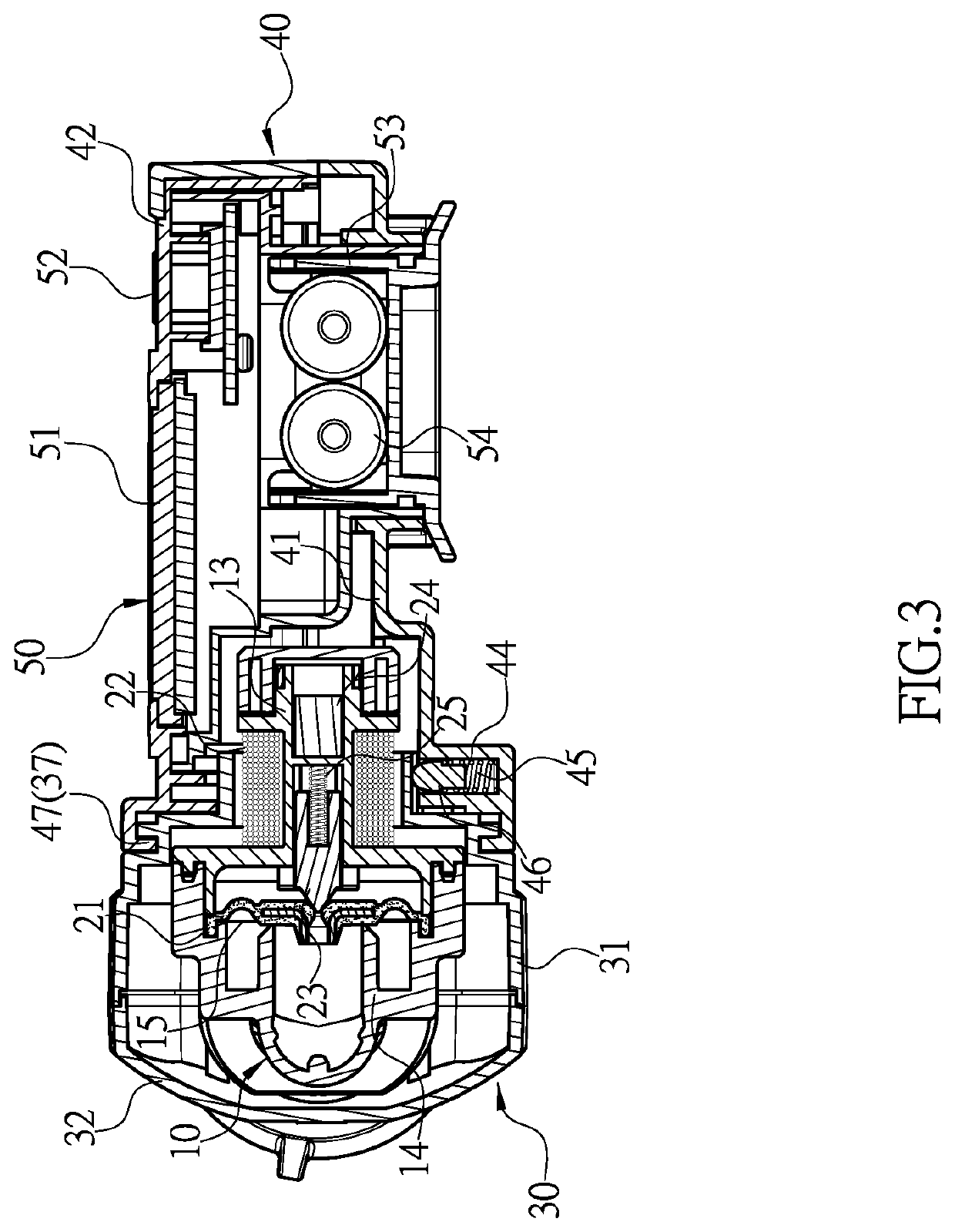

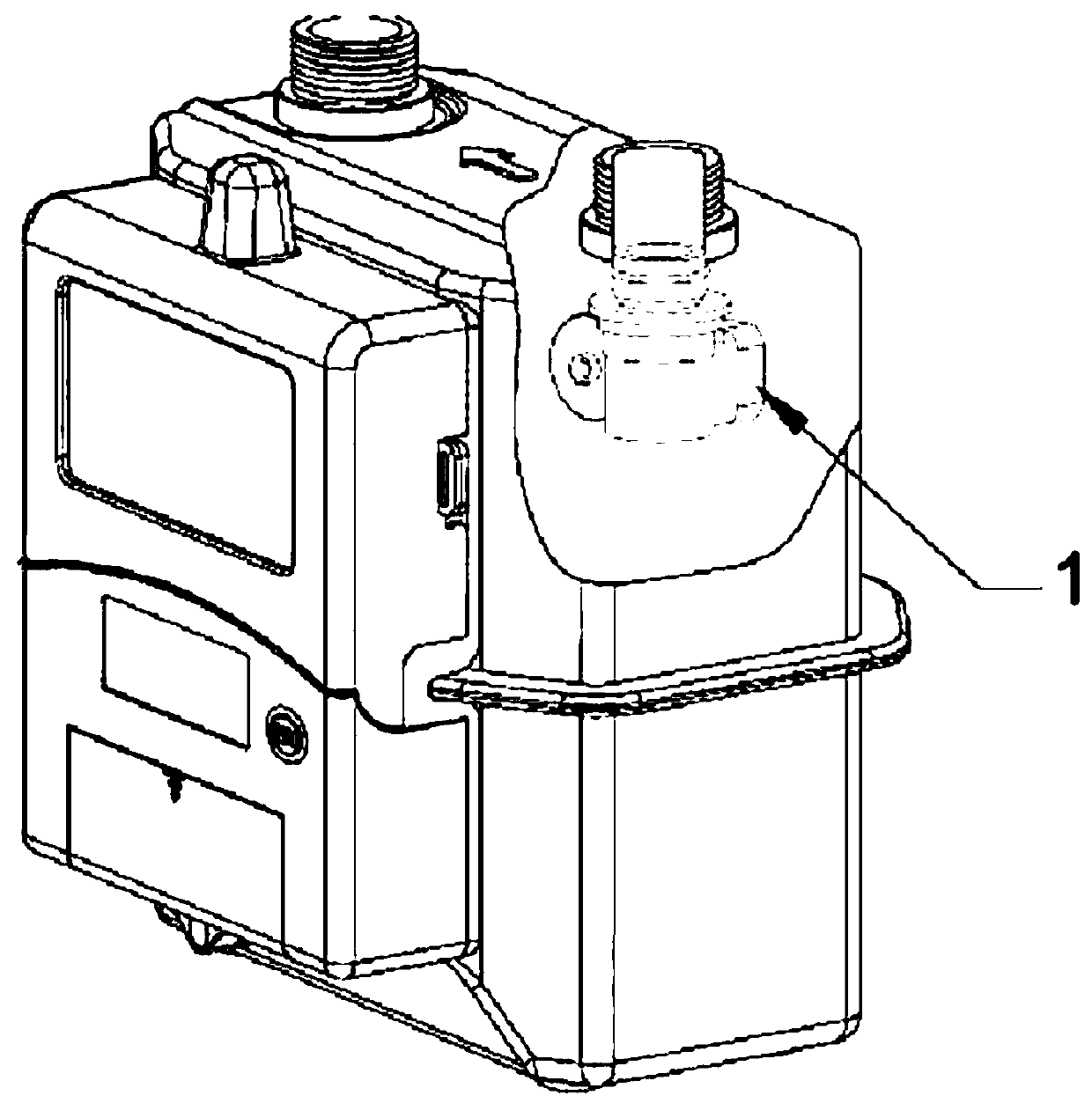

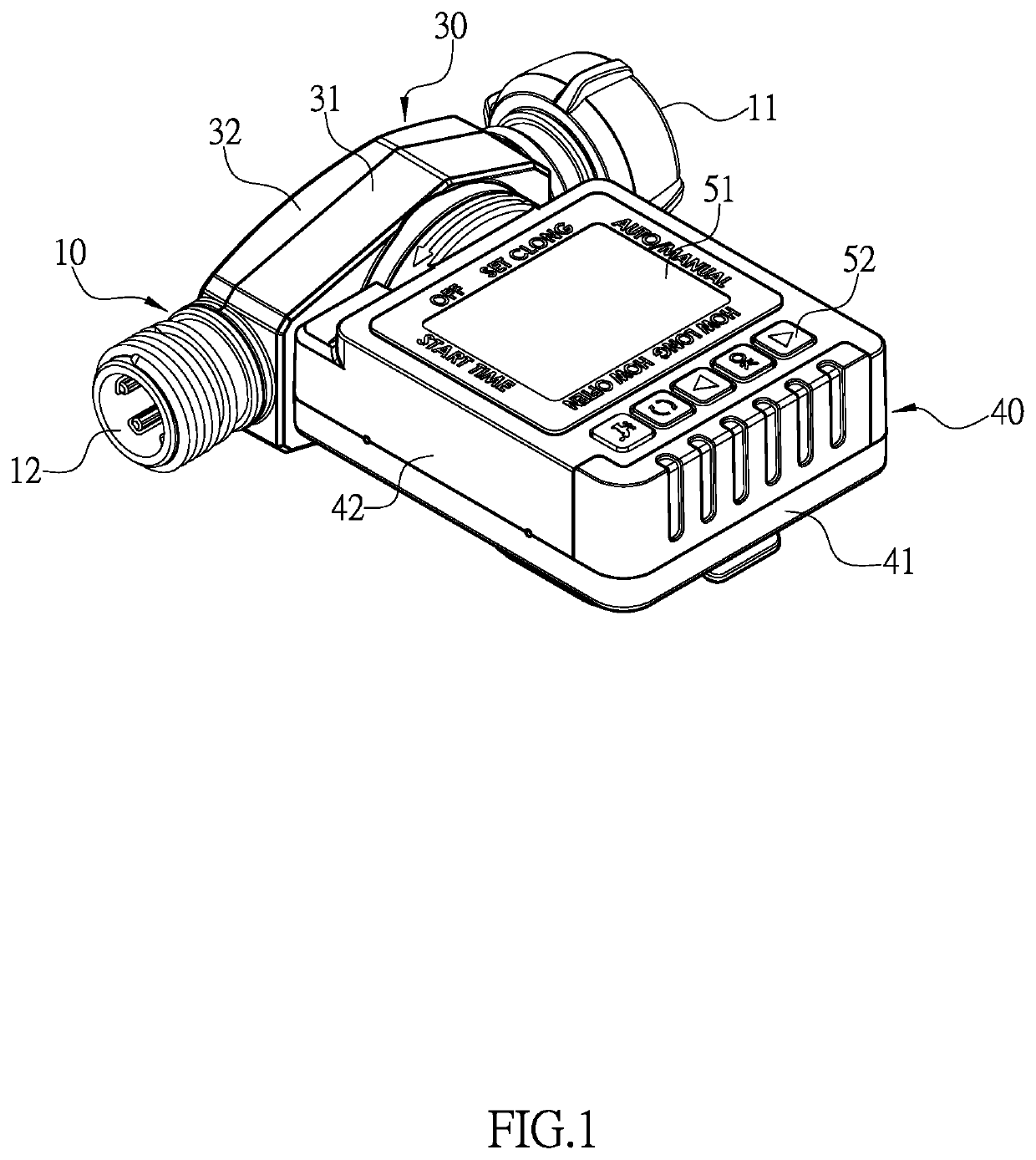

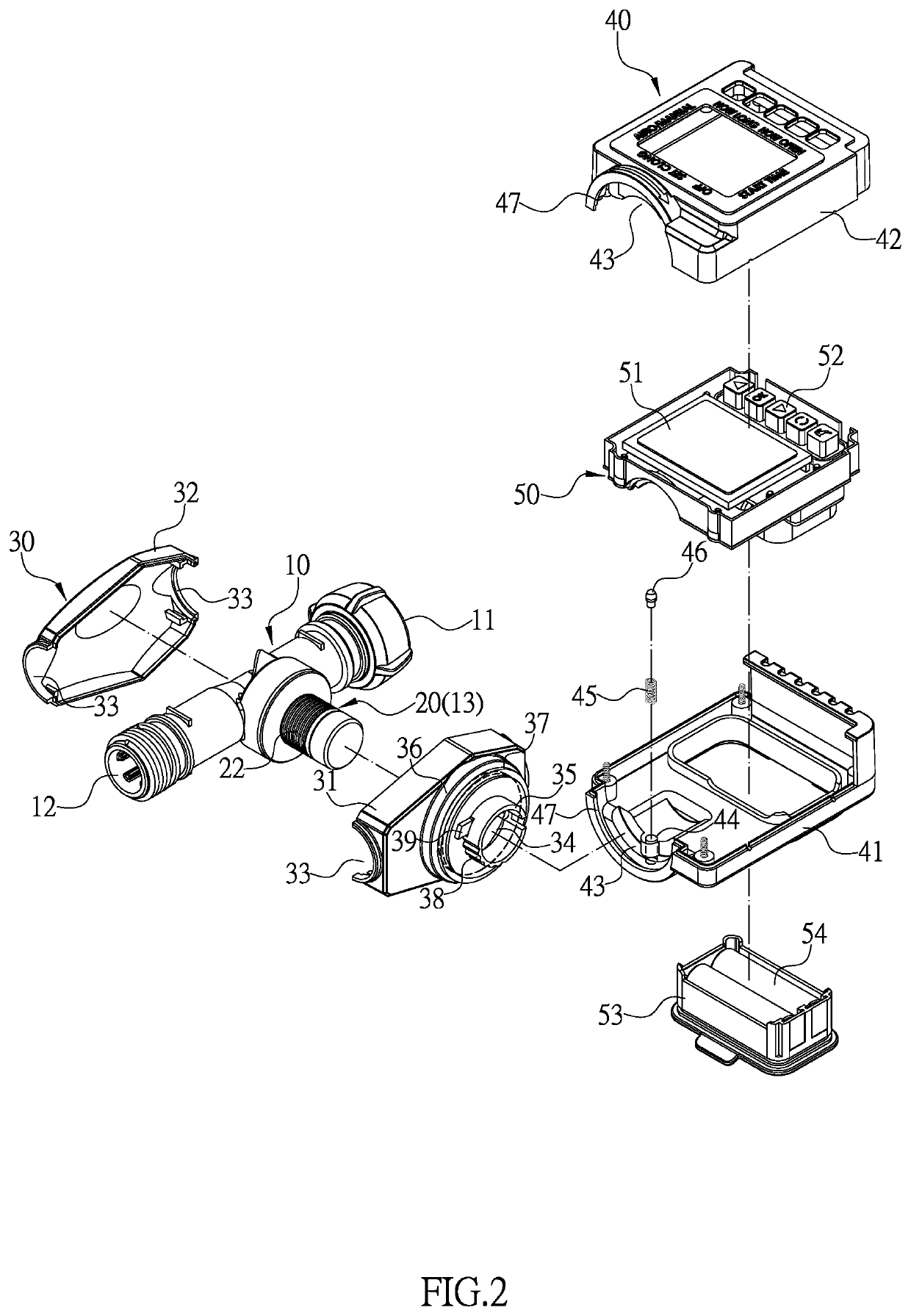

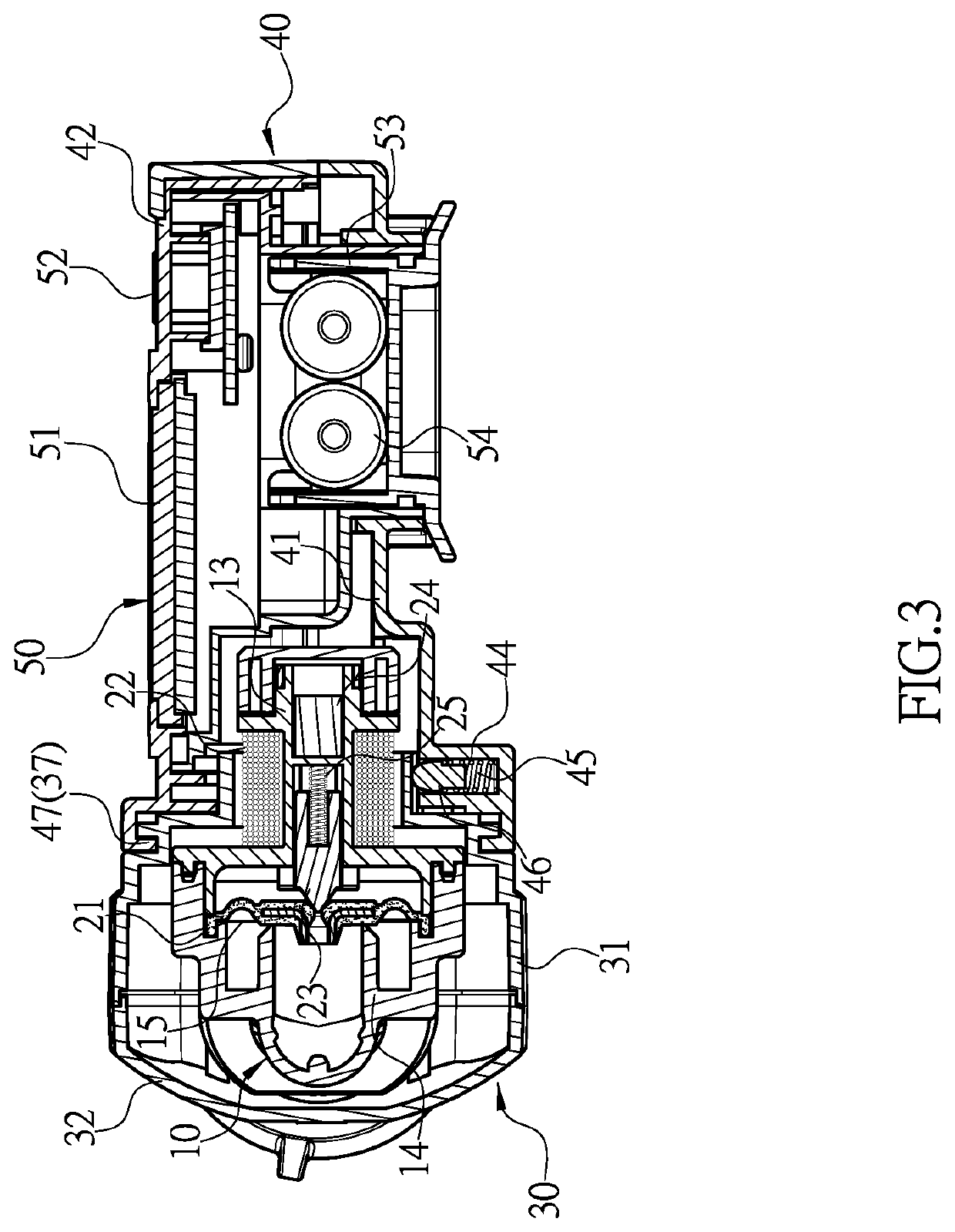

Digital water timer

ActiveUS10959385B1Easy to operateEasy to displayOperating means/releasing devices for valvesStatic indicating devicesEngineeringHydrology

A digital water timer may include a main body, a water valve, a locating base, a driving base, and a timer. The main body has a water inlet and a water outlet, and a valve tube protrudes from a lateral side of the main body. The water valve connected to the main body is controlled by the timer to achieve on / off operation of channels inside the main body. The locating base is secured on the main body, and the driving base is adapted to have rotation relative to the locating base and be secured at a specific position after rotated. The timer installed in the driving base comprises a display panel and an operation interface which are exposed externally for operation. The driving base with the timer is rotated relative to the locating base, and the display panel is adjusted as needed to provide an optimal view for operation.

Owner:SHIN TAI SPURT WATER OF THE GARDEN TOOLS

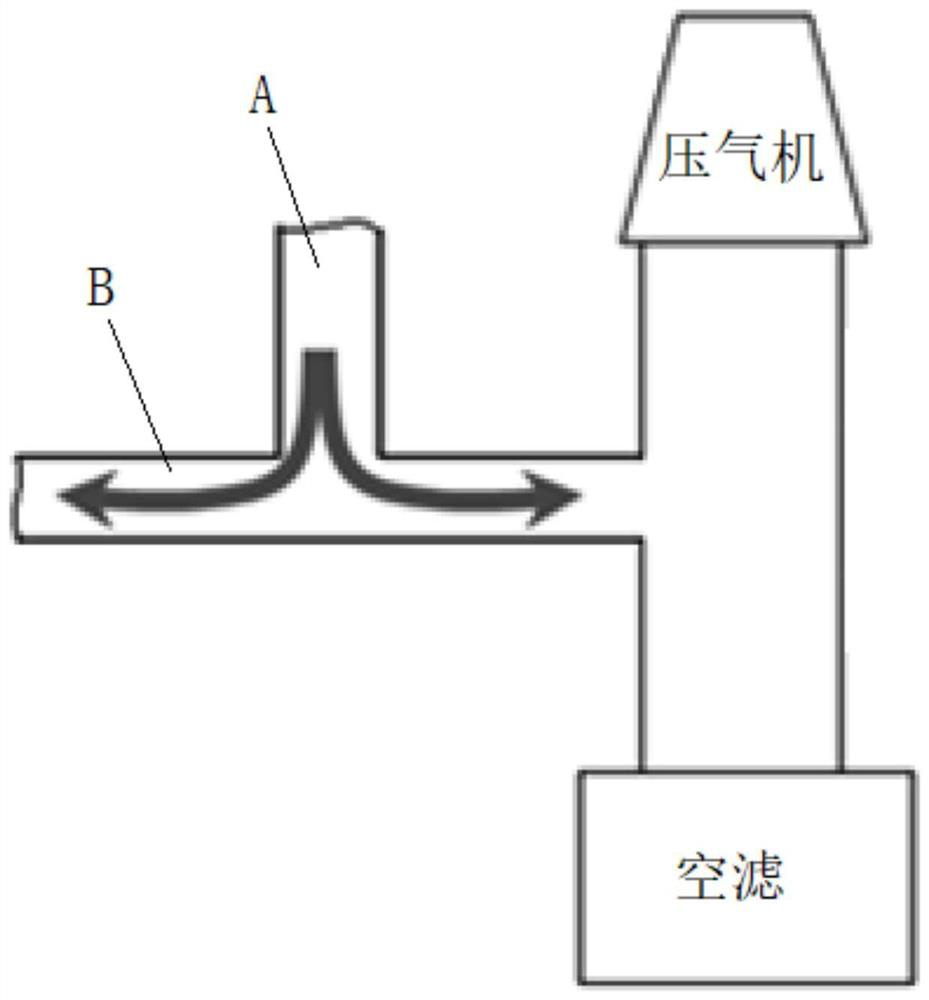

Structure for increasing negative pressure

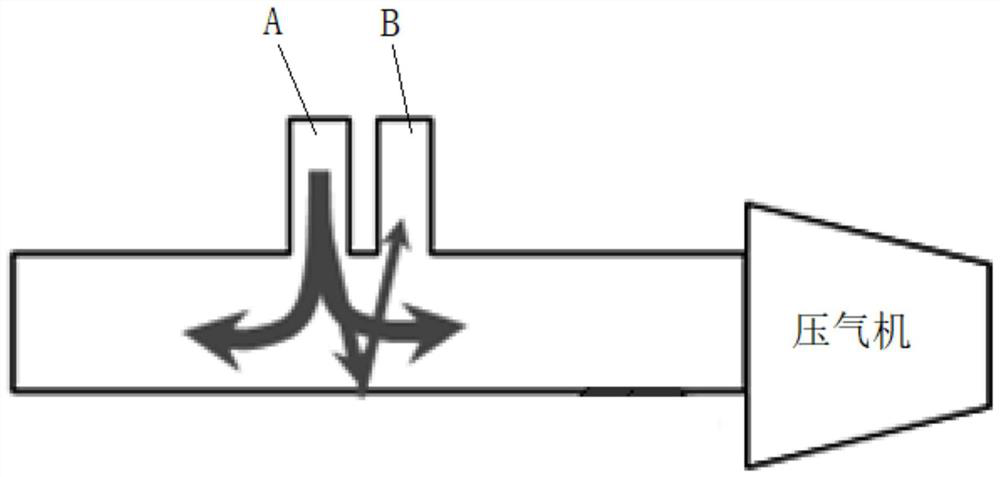

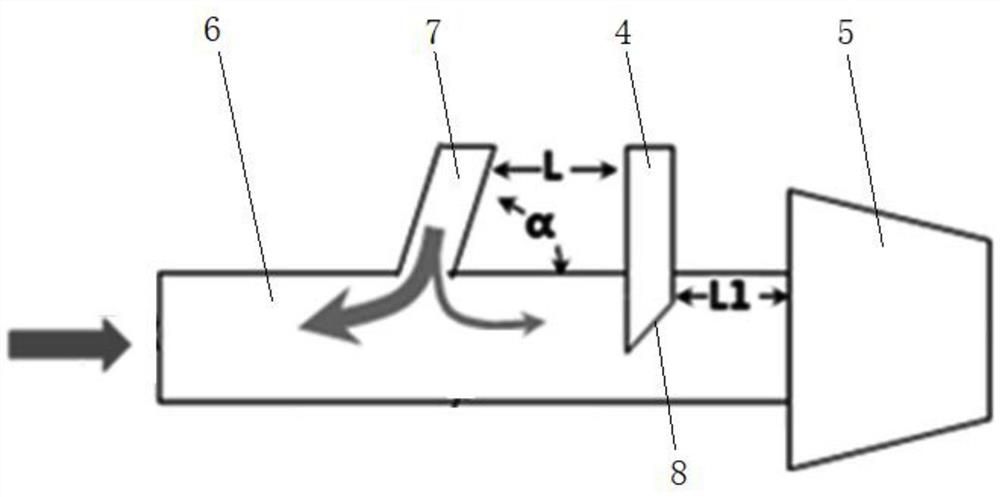

PendingCN112031894AReduce the impactGreat suctionMachines/enginesCrankcase ventillationSuction forceGas compressor

The invention discloses a structure for increasing negative pressure, relates to an engine, and solves the technical problem that the pressure of an existing crankcase cannot be steadily less than atmospheric pressure. The structure comprises a closed circulating crankcase, a supercharger and an oil-gas separation mechanism, wherein a vent pipe of the crankcase is connected with an air inlet passage at the front end of a gas compressor through the oil-gas separation mechanism, and the vent pipe is positioned between an anti-surge valve pipe and the gas compressor; the distance between the ventpipe and the gas compressor is smaller than the distance between the vent pipe and the anti-surge valve pipe; and one end of the vent pipe obliquely extends towards the direction of the gas compressor or is provided with a first oblique notch facing the gas compressor. The distance between the vent pipe and the gas compressor is smaller than the distance between the vent pipe and the anti-surge valve pipe, and one end of the vent pipe obliquely extends towards the direction of the gas compressor or is provided with the first oblique notch facing the gas compressor, so that the influence of airflow of an anti-surge pipe on the vent pipe can be reduced, suction force of the gas compressor to air in the crankcase is increased, and the pressure of the crankcase is steadily less than the atmospheric pressure.

Owner:GUANGXI YUCHAI MASCH CO LTD

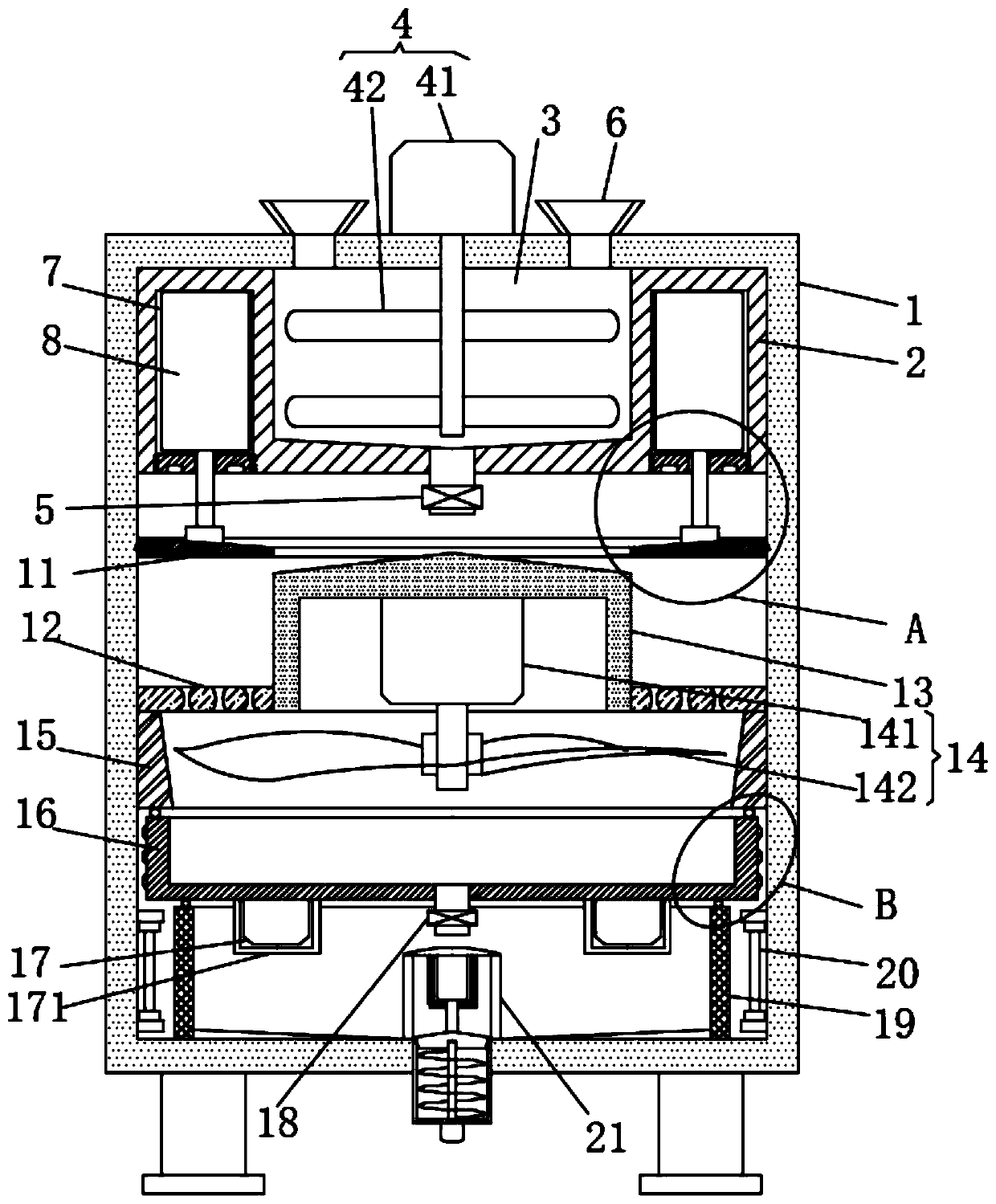

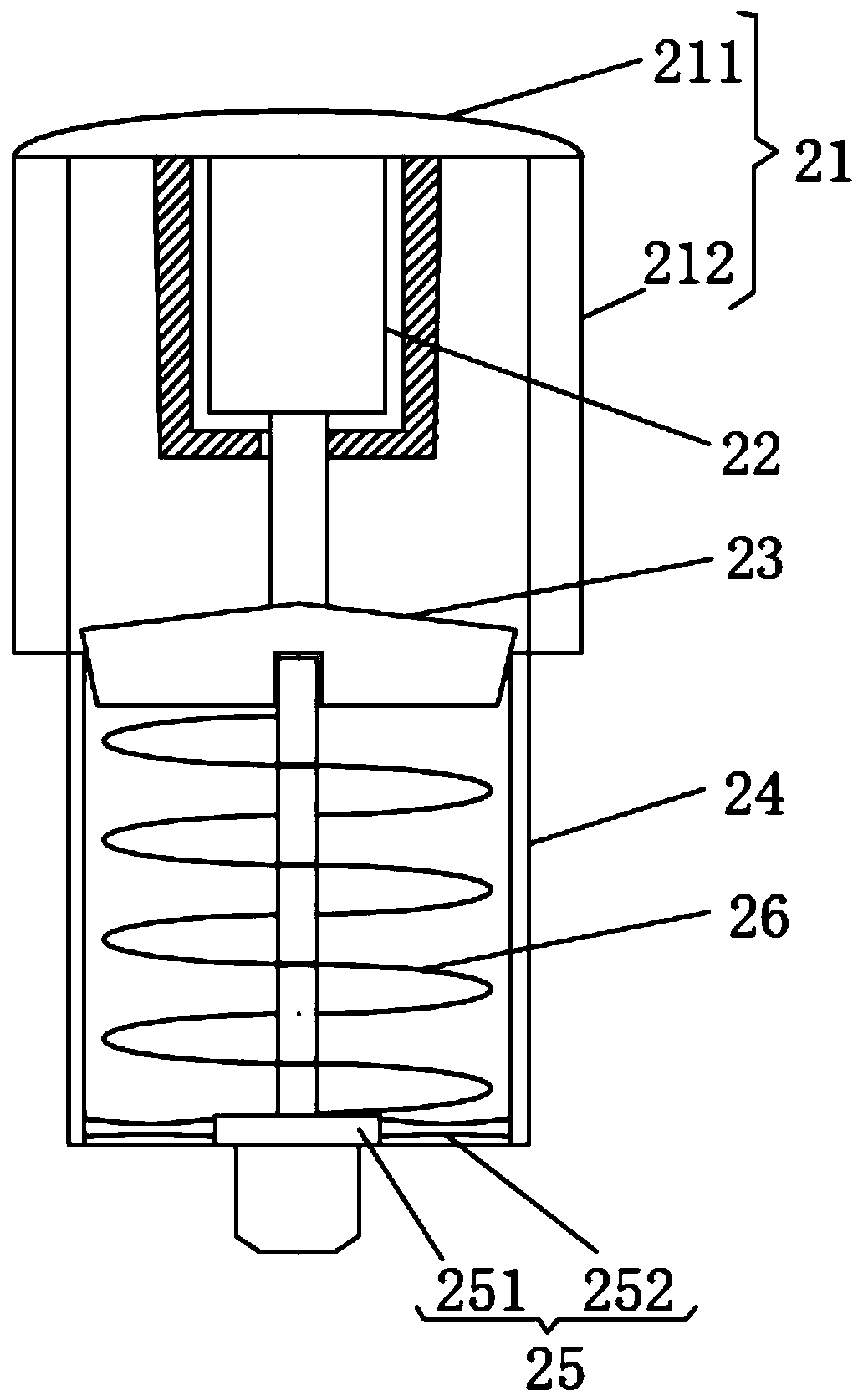

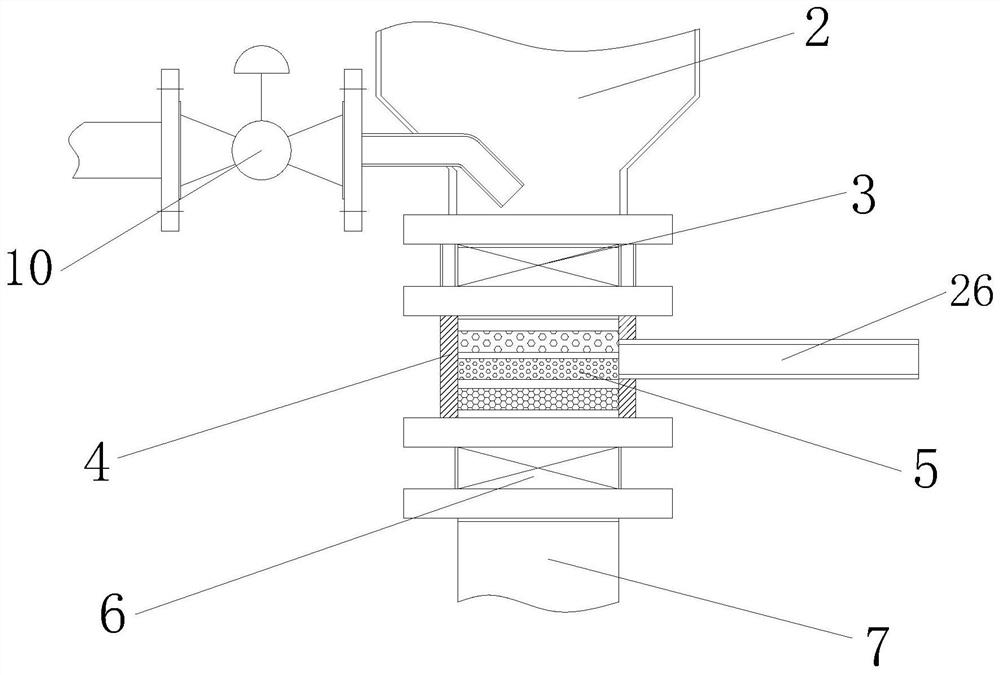

Full-automatic sterile granulator for pill production

InactiveCN110917991AReasonable structureFunctionalGranulation by material expressionRadiationMechanical engineeringPill product

The invention relates to the technical field of granulators and particularly relates to a full-automatic sterile granulator for pill production. The granulator comprises a granulator body, a pretreatment frame is arranged on an inner wall of the granulator body, a mixing bin is formed in a top surface of the pretreatment frame, a mixing assembly is arranged in the mixing bin, a first discharging valve pipe is inserted into a bottom surface of the mixing bin, a feeding hopper is arranged on a top plate of the granulator body, and a machine bin is formed in a bottom surface of the pretreatment frame. The full-automatic sterile granulator has the advantages that: the full-automatic sterile granulator provided by the invention integrates mixing, stirring, extruding into strips, cutting and shaping, and sterilizing and drying equipment into a whole, the continuous work of pill production is achieved, the transfer frequency in the material processing process is reduced, and therefore the contact time of the materials and the outside is shortened, and after sterilization is conducted through an ultraviolet sterilization lamp, the sterile performance of pill products is improved.

Owner:李智薇

Control valve used for dust removing system

InactiveCN105927740ACompact structureReasonable designOperating means/releasing devices for valvesDispersed particle filtrationCrankDust control

The invention relates to a control valve used for a dust removing system. The control valve is characterized in that the control valve comprises a valve base, a rotating shaft, a butterfly-shaped door, a crank and a swing rotation drive mechanism; the valve base comprises a base plate and a valve pipe; the base plate is provided with a fixed installation hole; the rotating shaft is vertically arranged and penetrates the valve pipe in the radial direction; the upper end of the rotating shaft is supported to the top of the valve pipe through an upper bearing assembly; the lower end of the rotating shaft is supported to the bottom of the valve pipe through a lower bearing assembly; the butterfly-shaped door is arranged in the valve pipe; the shape and the size of the butterfly-shaped door are matched with those of the valve pipe; the butterfly-shaped door is fixedly installed on the rotating shaft; one end of the crank is fixed to a shaft head at the upper end of the rotating shaft; and the other end of the crank is connected with the swing rotation drive mechanism which can drive the rotating shaft and the butterfly-shaped door to rotate by driving the crank to swing, and therefore the control valve is closed to be opened or closed. The control valve used for the dust removing system is compact in structure, reasonable in design, convenient to operate and control, safe, reliable, and capable of effectively controlling and adjusting negative pressure in a negative pressure pipeline and achieving the energy saving and efficiency improving purposes.

Owner:WUXI ZHOUXIANG LASER MACHINERY

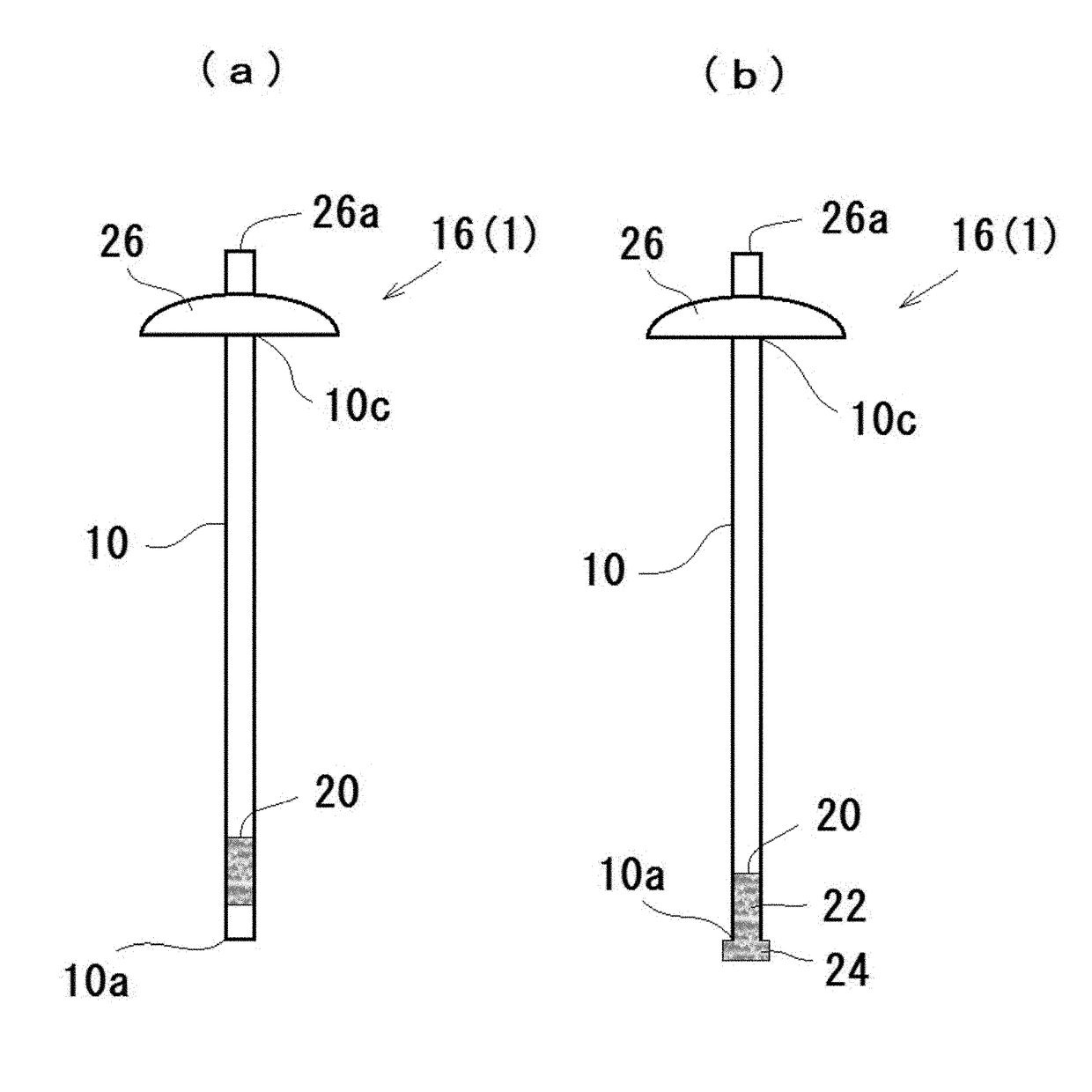

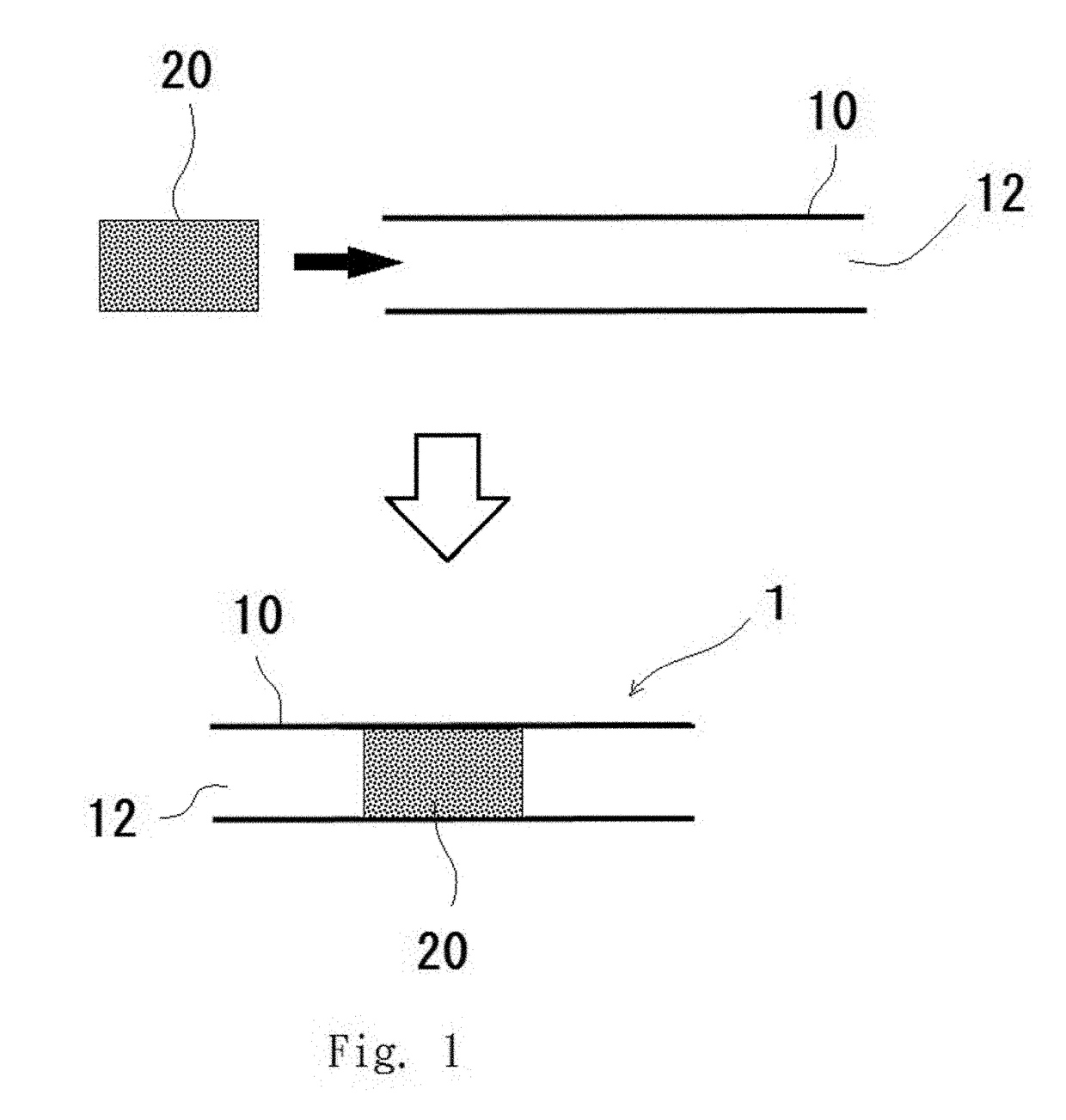

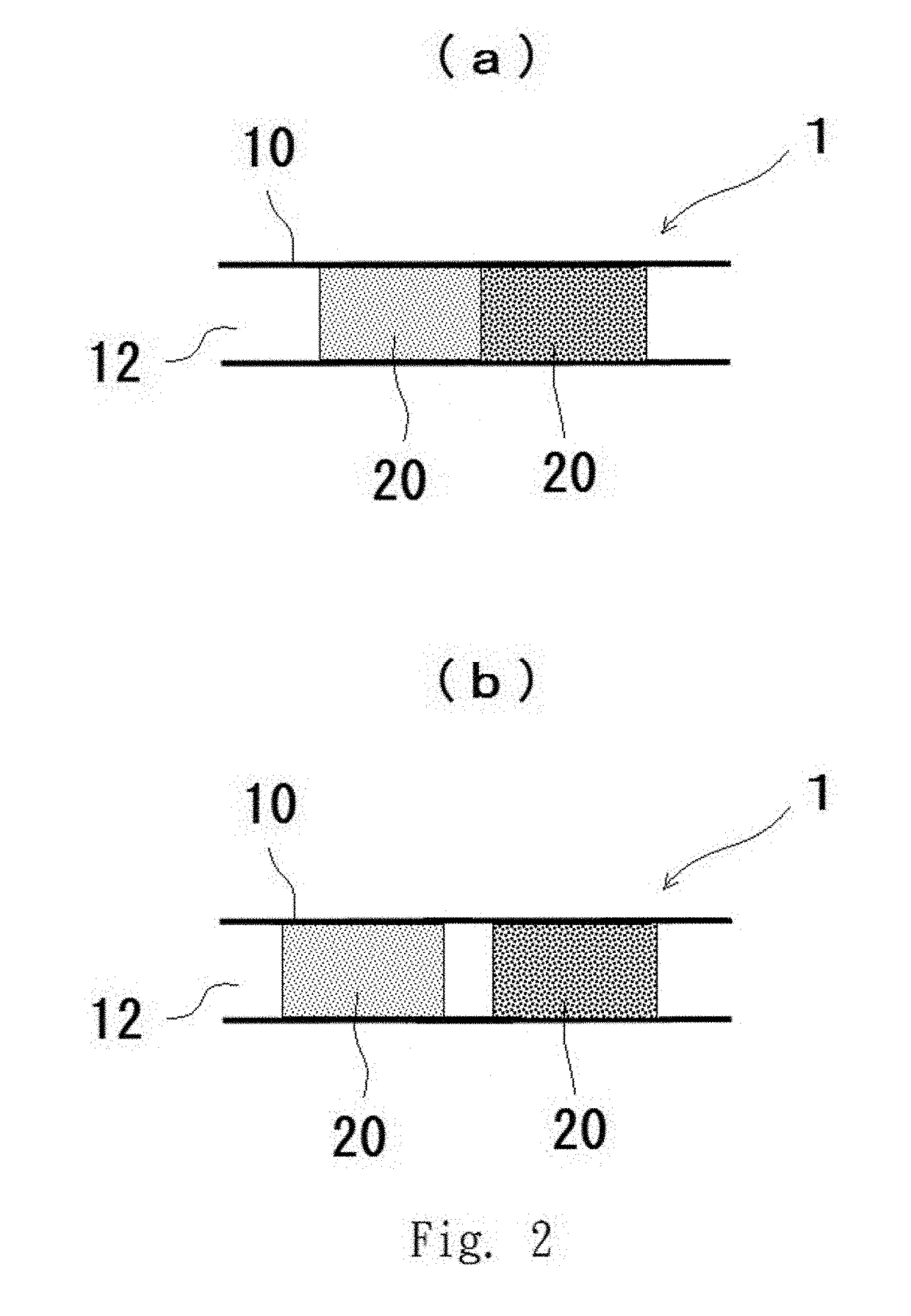

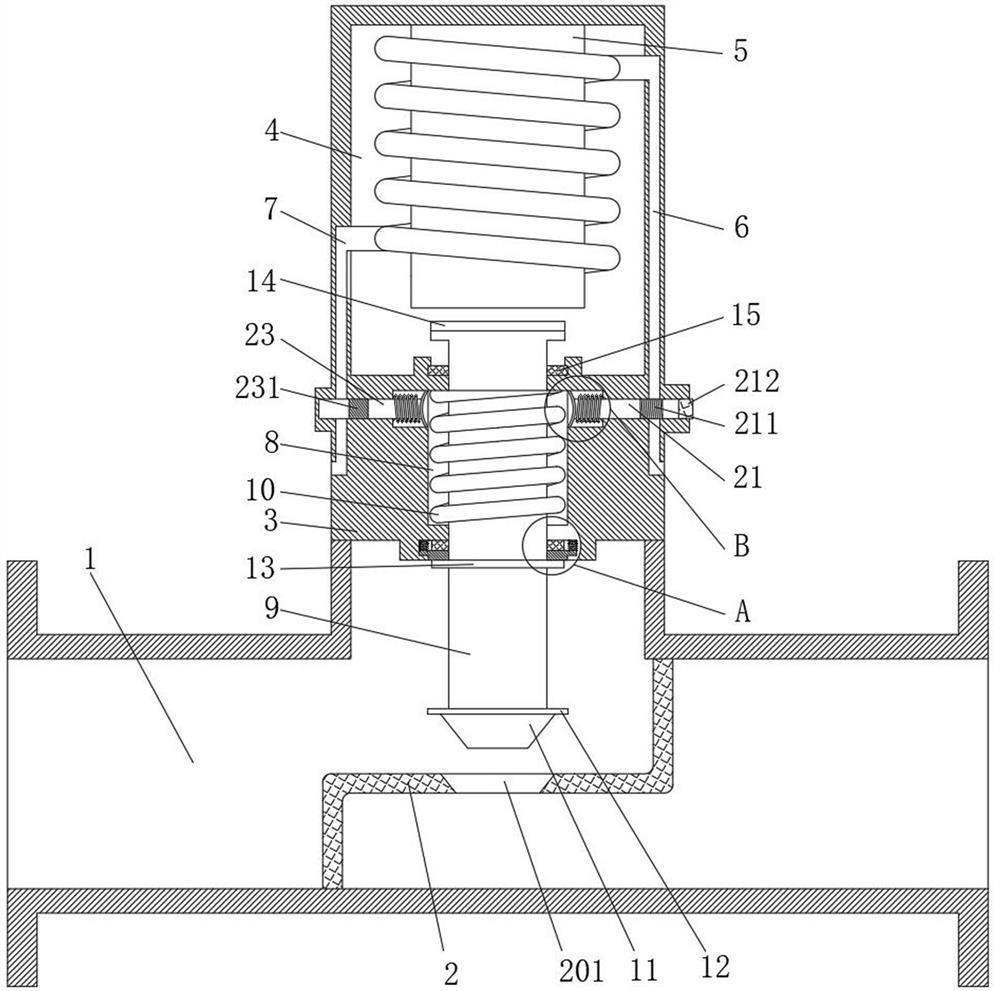

Flow pipe, and jet nozzle pipe and aerosol valve pipe using said flow pipe

ActiveUS20180257847A1Good effectReliable StirringLiquid spraying apparatusLiquid dispensingEngineeringForeign substance

[Problem] To provide a flow path tube that prompts gas / liquid stirring of fluids flowing through a tube channel, enables adjustment of the flow rate, and furthermore suppresses passage of foreign substances.[Solution means] A flow path tube 1 is configured by inserting and disposing within a tube channel 12 of a flow path tube body 10 at least one or more porous materials 20 having a continuous void structure and a necessary length / a necessary diametrical dimension. Moreover, at least one or more ejection holes 18 are formed at given positions in the flow path tube body 10 or in the porous material 20 to form a jet nozzle tube 14 using the flow path tube 1. Furthermore, a valve body 26 is attached to the base end 10c of the flow path tube body 10 to form an aerosol valve tube 16 using the flow path tube 1.

Owner:OGAWA OSAMU

Colonoscope clinical examination tool in gastroenterology department

InactiveCN111329439AReduce frictionAvoid discomfortSurgeryEndoscopesCatheterGastroenterology department

The invention discloses a colonoscope clinical examination tool in the gastroenterology department. The colonoscope clinical examination tool comprises a catheter, two through holes, a camera shootingunit, an air bag, a lubricating mechanism, a threaded sleeve head, an impurity conveying pipe, a storage mechanism, a valve pipe, an air delivery pipe, a handle and a conveying pipe, wherein the twothrough holes are formed in the side face of the catheter; the camera shooting unit is arranged at one end of the catheter; the handle is arranged at the other end of the catheter; the lubricating mechanism is arranged on the outer wall of the catheter; the air bag is arranged in a groove in the outer wall of the catheter; the air delivery pipe is arranged in an inner cavity of the catheter; and one end of the air delivery pipe is connected with the air bag. According to the colonoscope clinical examination tool, friction between the catheter and the inner wall of an intestinal tract can be effectively reduced, discomfort and pain brought to an examinee are avoided, the air bag is promoted to expand to make contact with the inner wall of the intestinal tract so as to fix the catheter and the camera shooting unit, examination is more stable, and inaccurate examination caused by the fact that impurities block a lens in the examination process is avoided.

Owner:李金霞

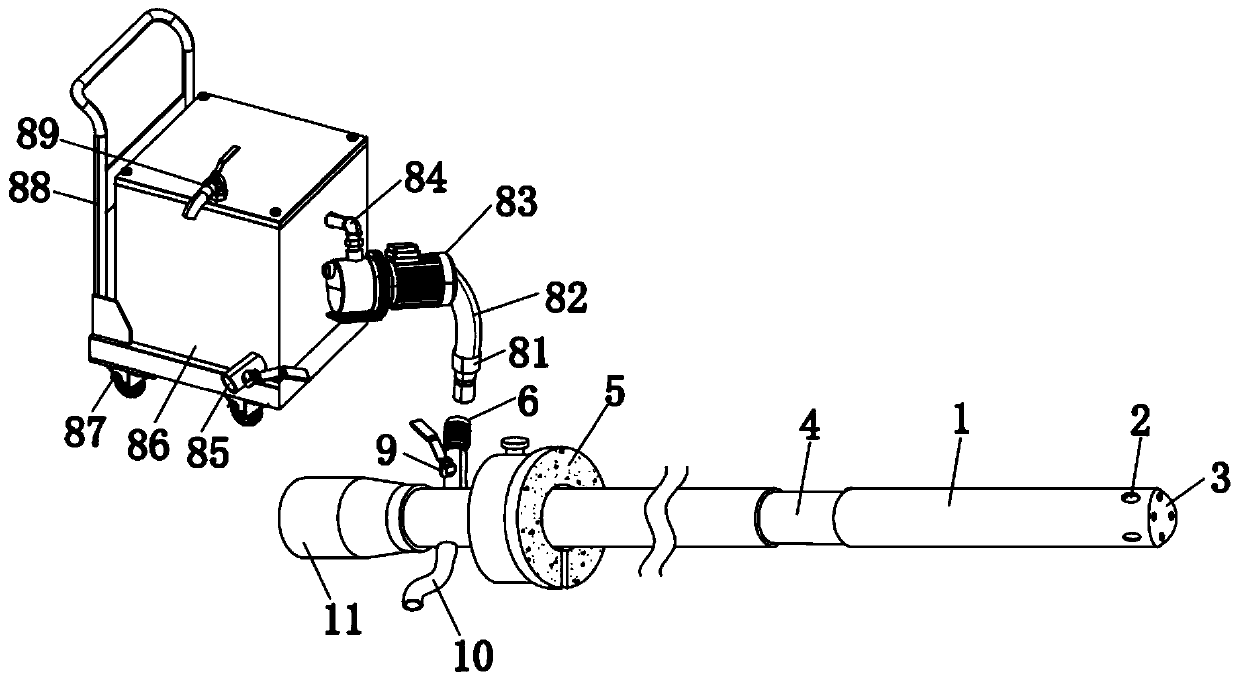

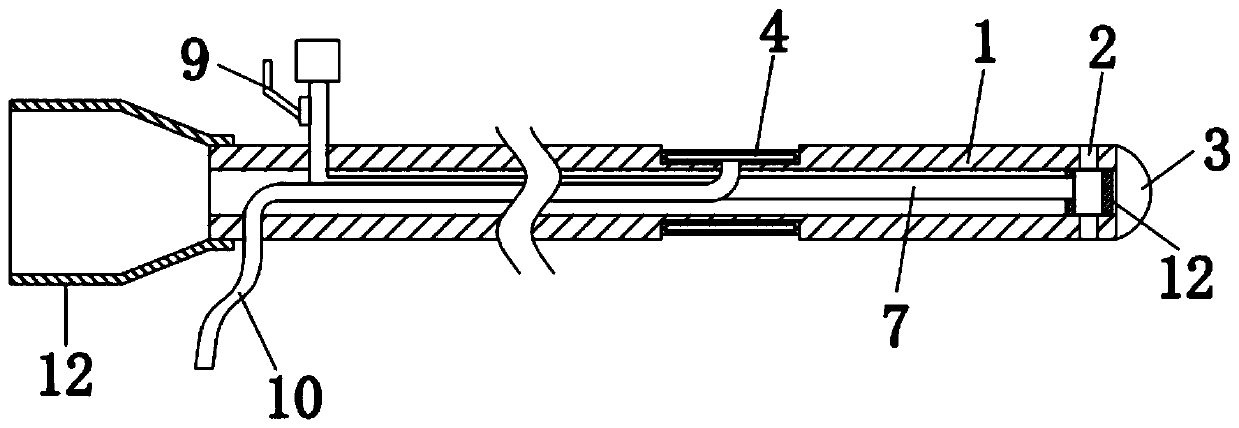

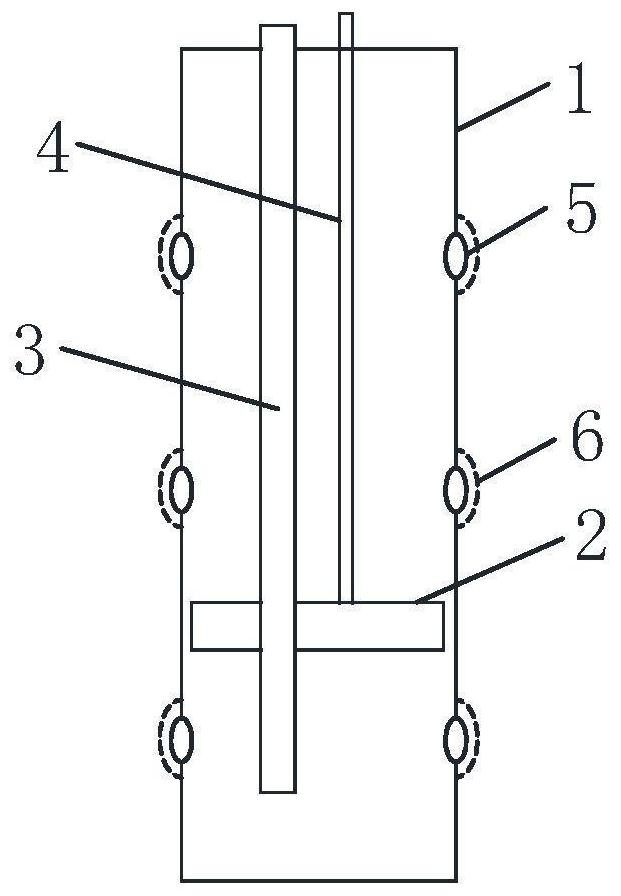

Tunnel ground surface directional large-diameter deep hole grouting device and grouting method

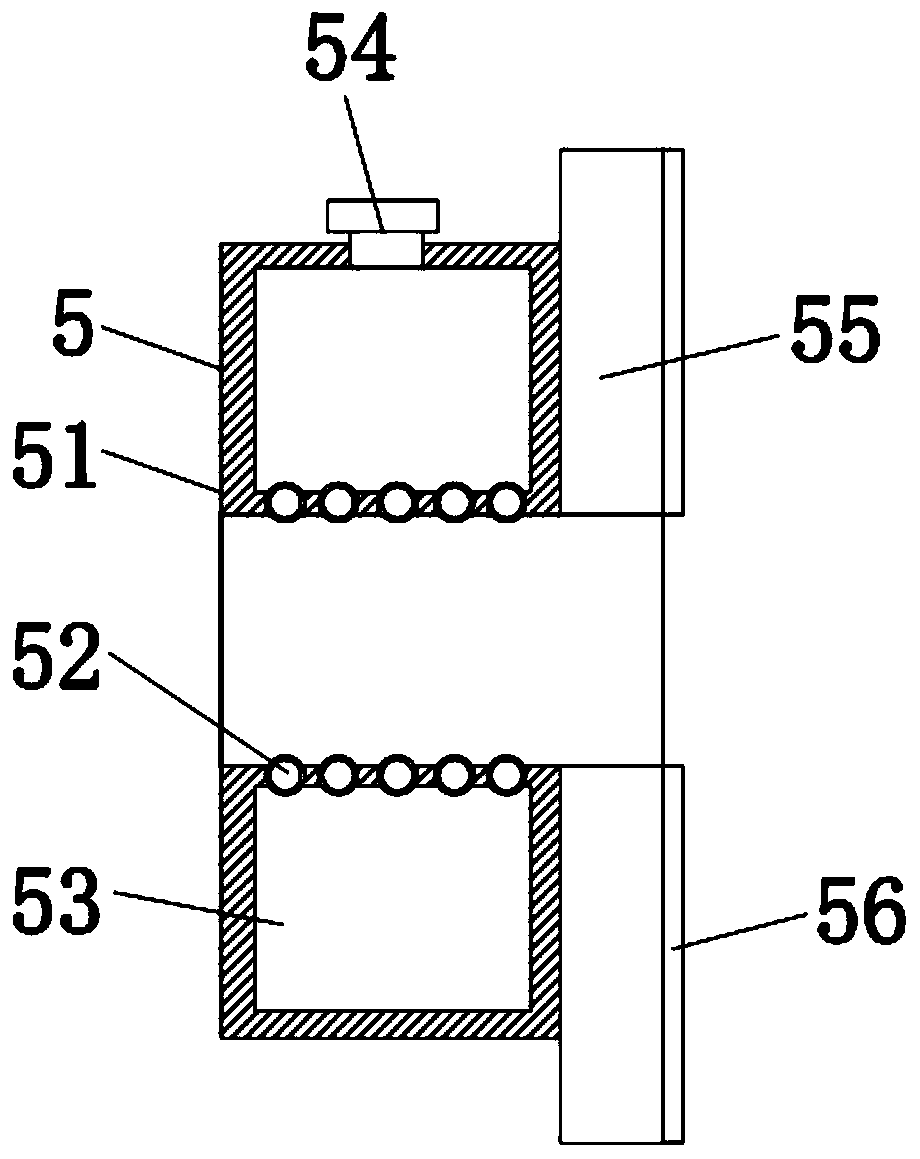

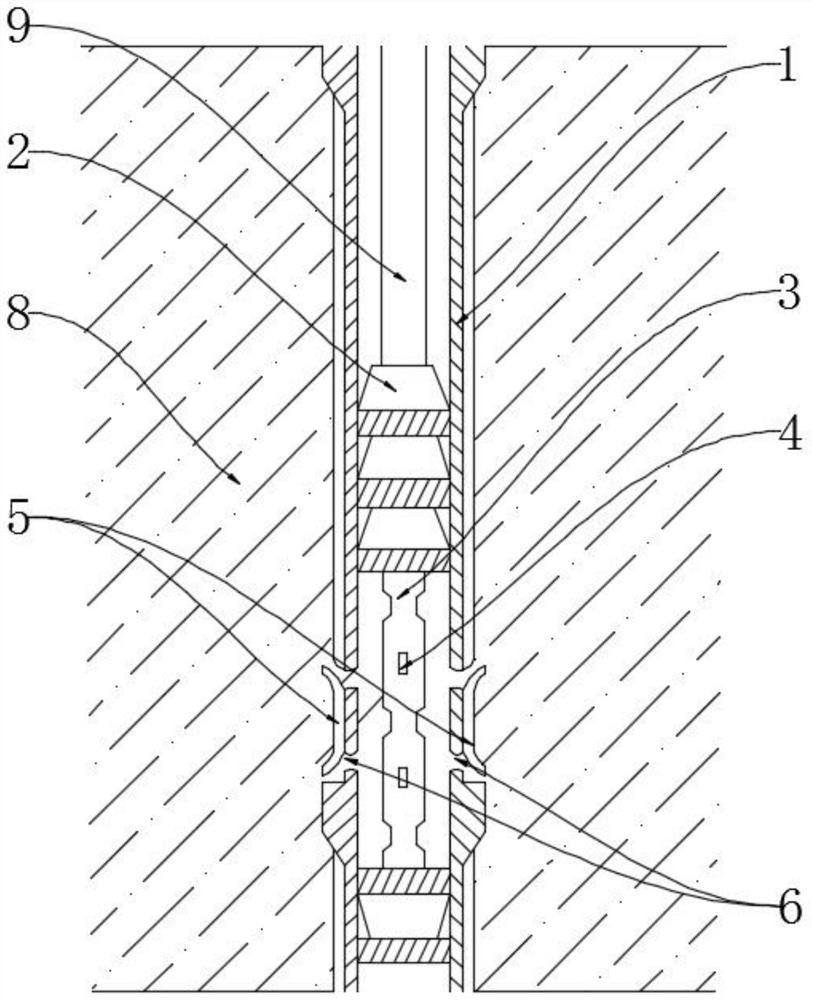

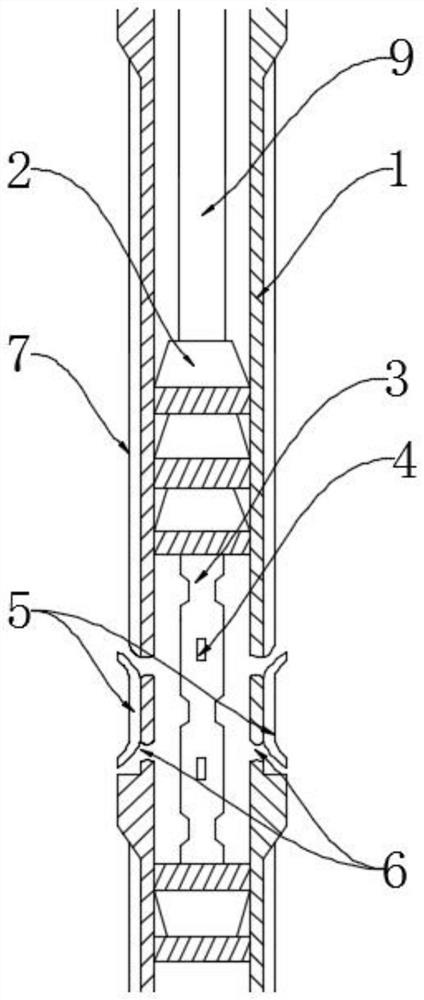

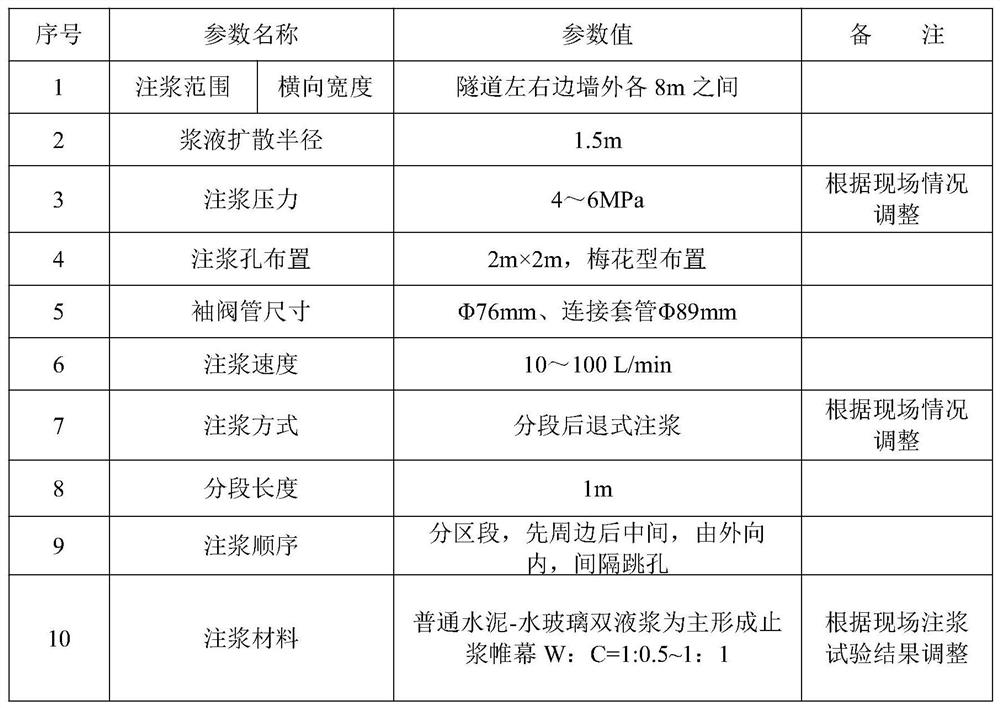

PendingCN111810198AImprove stabilitySave man hoursUnderground chambersExcavationsSurface cleaningSleeve valve

The invention discloses a tunnel ground surface directional large-diameter deep hole grouting device and a grouting method. The tunnel ground surface directional large-diameter deep hole grouting device comprises a grouting passage drilled in a foundation layer; a grout outlet is formed in a plastic valve pipe; a rubber one-way valve is arranged on a casing; a grouting core pipe is arranged in theplastic valve pipe; a grouting mouth is formed in the grouting core pipe; one end of a grouting pipe communicates with the grouting core pipe; a sealing ring is arranged outside the grouting pipe ina sleeving manner; and the external surface of the sealing ring is attached to the internal wall of the plastic valve pipe. The grouting method comprises the following steps of grouting reinforcing ofa ground surface deep hole, sidewalk construction, ground surface cleaning and drilling machine platform dressing, drilling and grouting circulation selection, drilling, mounting of a sleeve valve pipe and grouting. According to the tunnel ground surface directional large-diameter deep hole grouting device and the grouting method, grouting reinforcing and tunnel excavation can be synchronously carried out, the work time can be saved, and moreover, the surrounding rock stability can be effectively improved, and as vertical grouting reinforcing can also be carried out on a deep tunnel, the grouting difficulty is reduced, and the grouting reinforcing speed is increased.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD

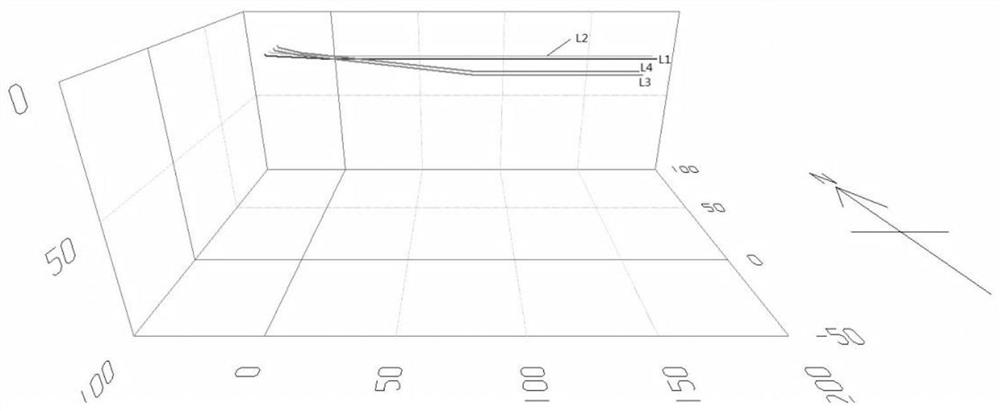

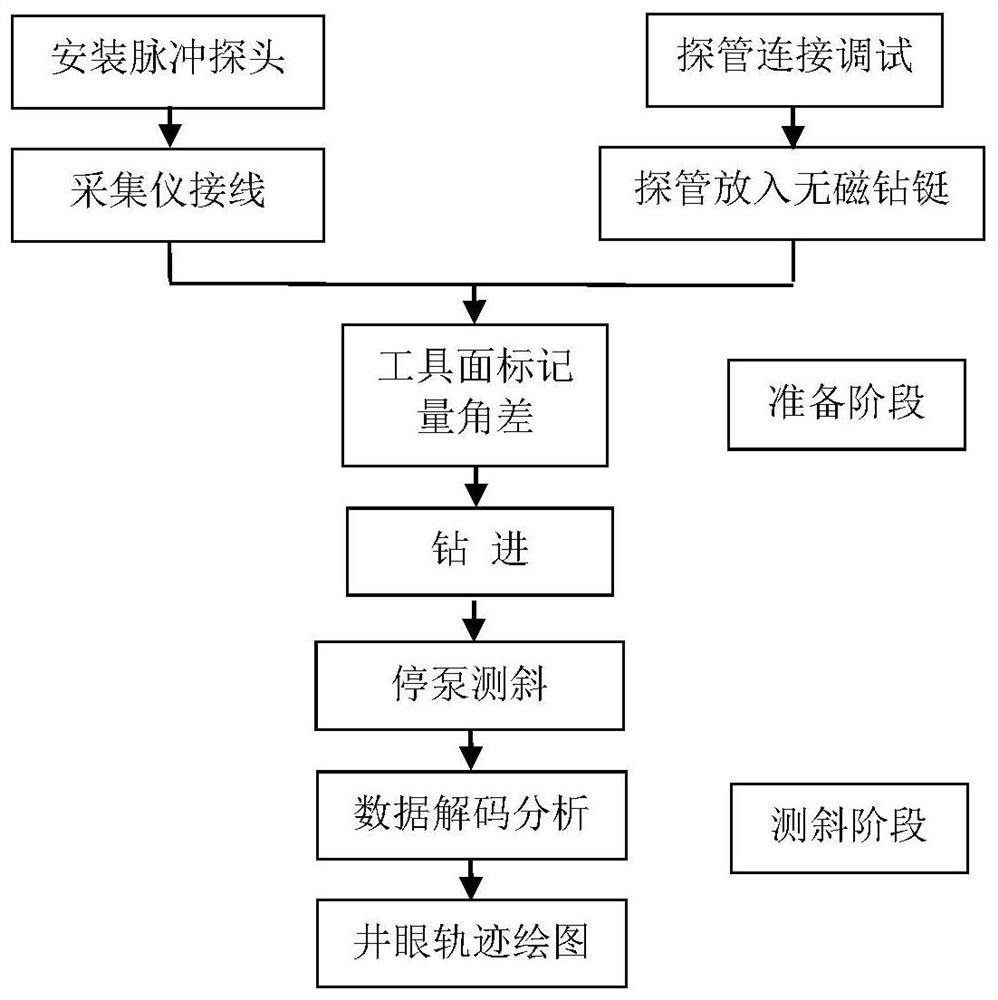

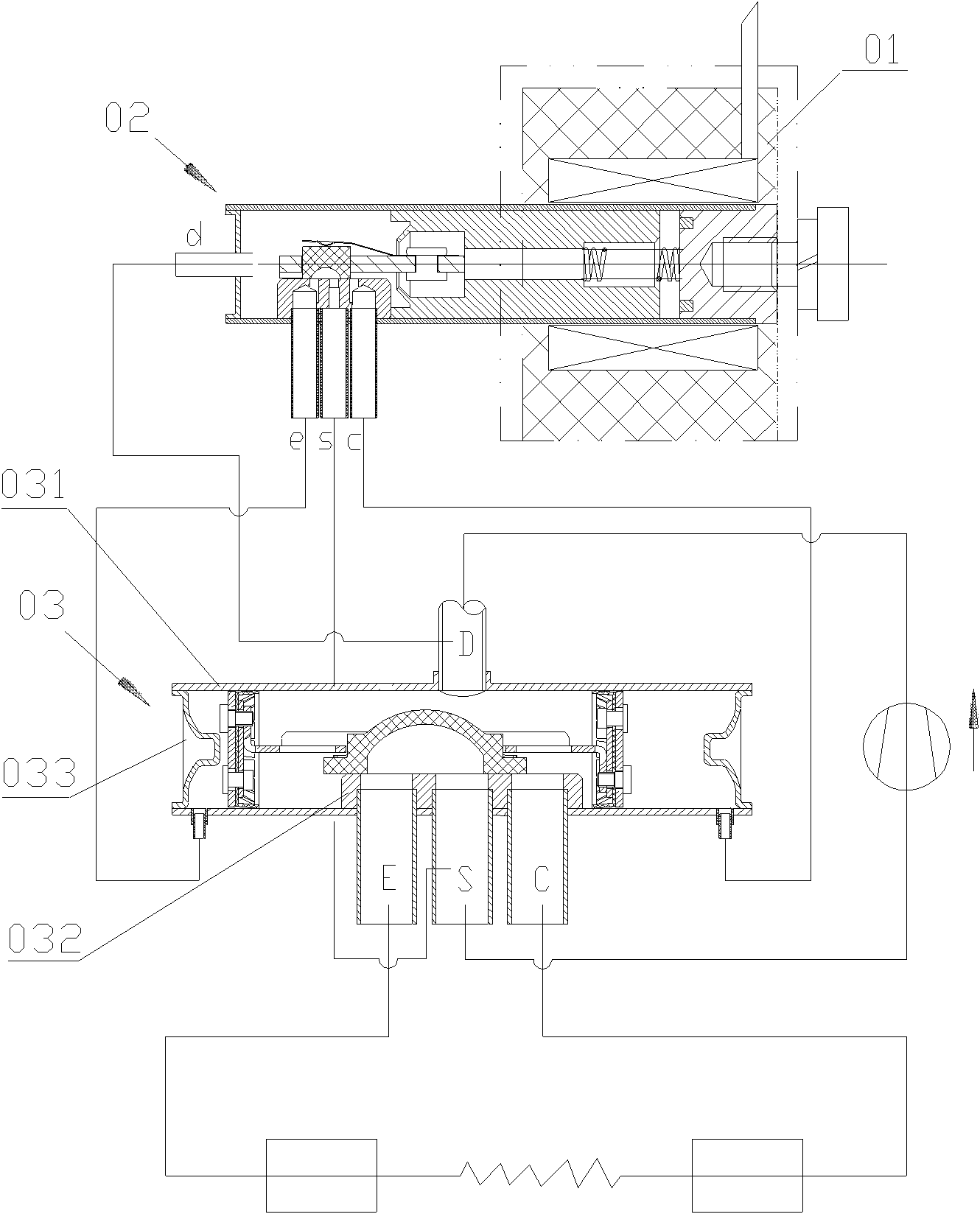

Horizontal positioning grouting reinforcement construction process suitable for municipal construction muddy soft soil stratum

PendingCN114060036AReduce loss rateAvoid crackingDirectional drillingTunnelsWater leakageStructural engineering

The invention discloses a horizontal positioning grouting reinforcement construction process suitable for a municipal construction muddy soft soil stratum. The horizontal positioning grouting reinforcement construction process comprises the steps that A, drilling machine equipment is arranged on the ground or in a construction well, and the hole opening angle is selected according to the distance between a hole opening point and a target point; B, drilling holes are constructed in the middle of the muddy soft soil layer by adopting a directional drilling technology, and the drilling holes are composed of drilling deflecting section drilling holes and horizontal section drilling holes; C, after drilling construction is completed, installing a grouting sleeve and a grouting valve pipe in the drill hole; and D, injecting grouting materials into the muddy soft soil layer through the drilled holes for reinforcement. According to the process, the stratum loss rate in the municipal shield construction process can be effectively reduced, the stratum loss rate can be reduced to 1% or below, and potential safety hazards such as cracking and inclination of adjacent house structures caused by the fact that a shield downwards penetrates through or laterally penetrates through a building group are effectively avoided; the process can be used for preventing and treating the problems of separation of a ballast bed and a duct piece, tunnel water leakage and the like caused by uneven settlement of a muddy soft soil layer in the subway operation period.

Owner:SHANGHAI SHENTONG METRO +1

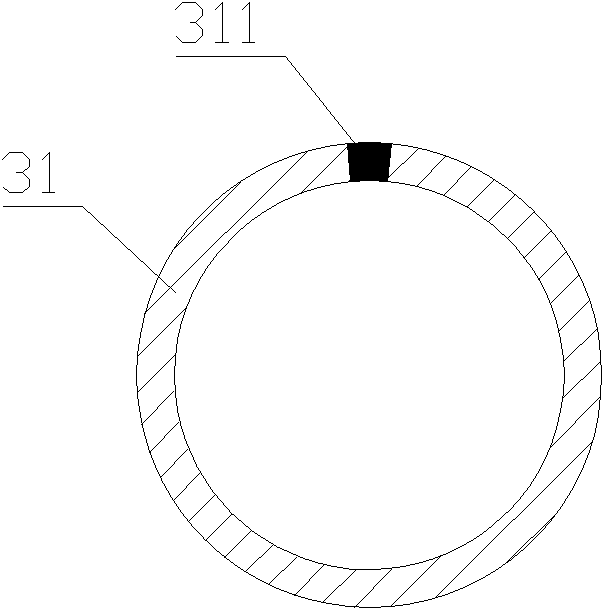

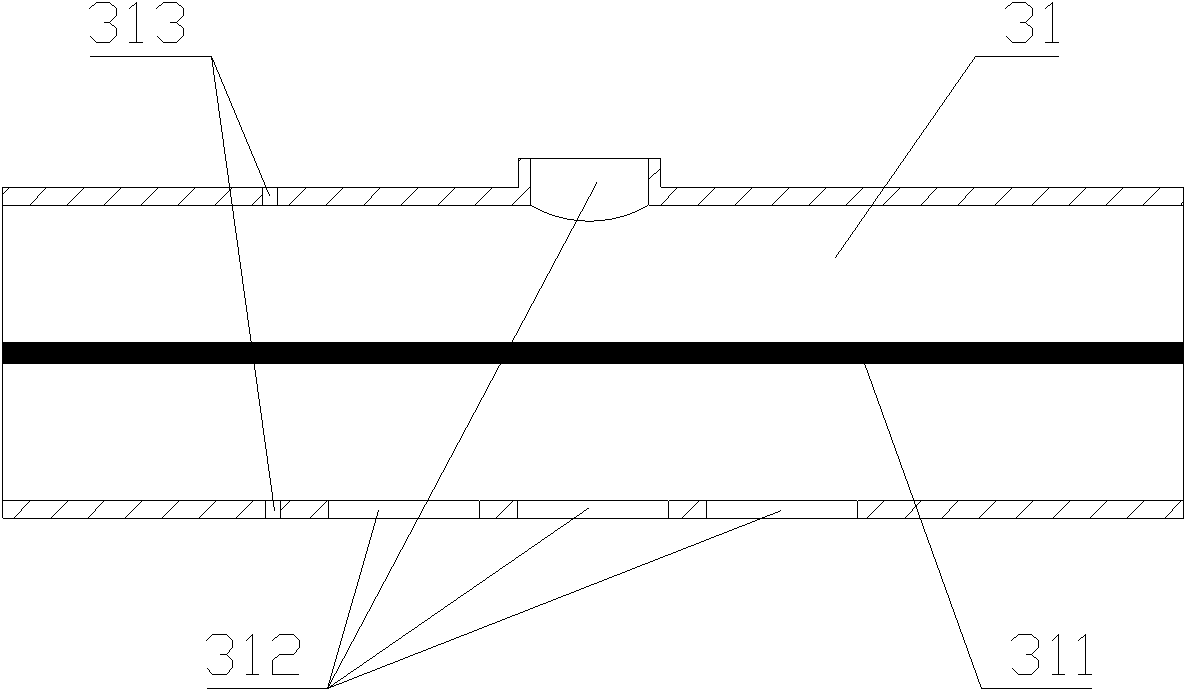

Master valve body of electromagnetic four-way reversing valve and electromagnetic four-way reversing valve with adoption of same

InactiveCN102434697AReduce processing timeSimple processValve housingsMachining processMachining time

The invention discloses a master valve body of an electromagnetic four-way reversing valve. The master valve body comprises a valve pipe, which is formed by coiling a stainless steel plate into a cylindrical tube and then performing seamless welding on a linear connecting seam on the cylindrical tube. For the master valve body, the traditional multi-pass drawing and multiple annealing distressing treatment and other process are cancelled, the master valve body is machined and molded by coiling the stainless steel plate and then performing seamless welding, so that not only is the machining time is greatly saved, but also the machining process is greatly simplified, and thus, the machining cost is greatly reduced and the master valve body is suitable for batch production and popularization. In addition, the invention further provides the electromagnetic four-way reversing valve, comprising an electromagnetic coil, a pilot valve and a master valve, wherein the master valve comprises the master valve body of the electromagnetic four-way reversing valve. According to the invention, the production cost of the electromagnetic four-way reversing valve is greatly reduced while the precision and the service life of the electromagnetic four-way reversing valve are guaranteed.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

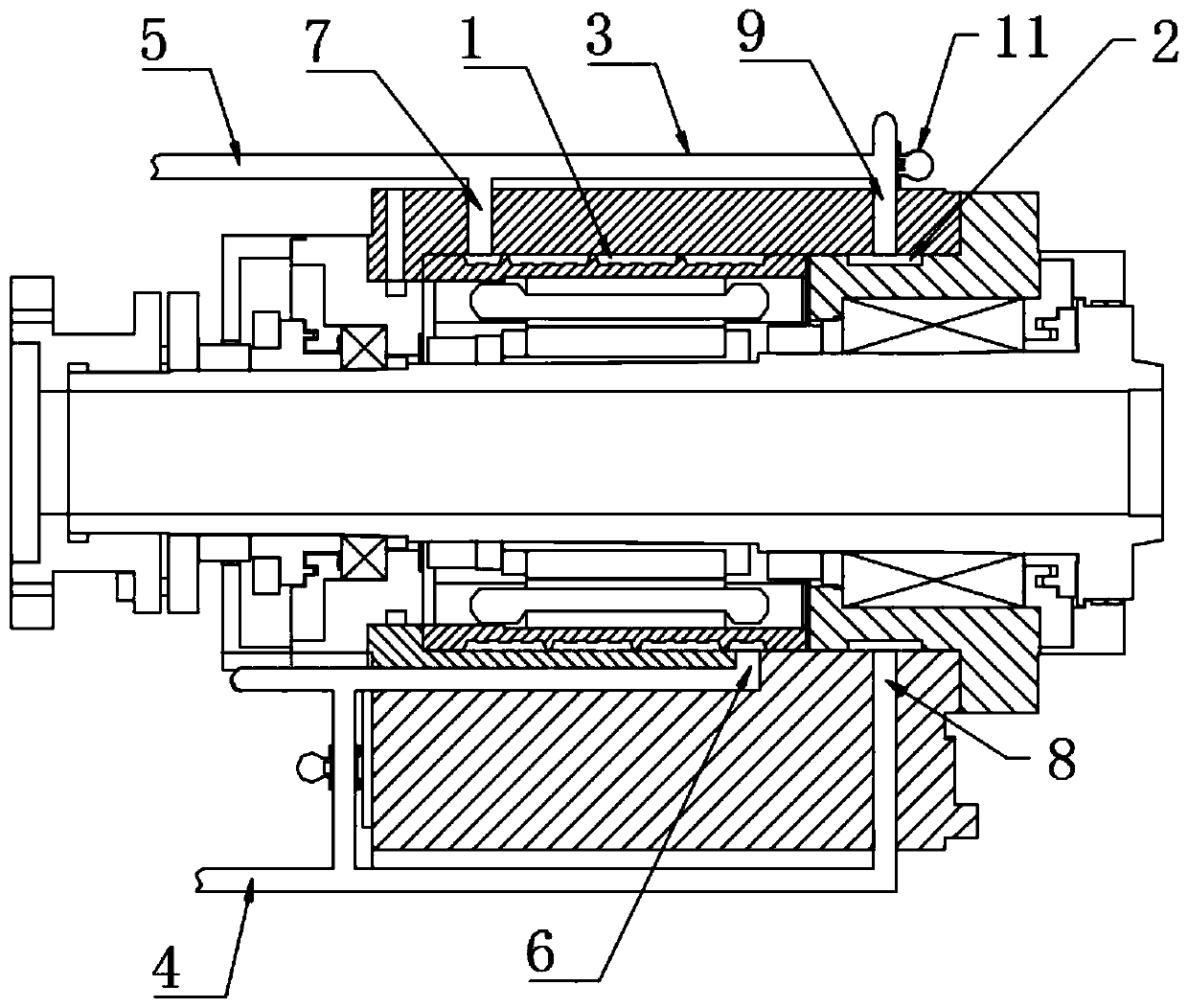

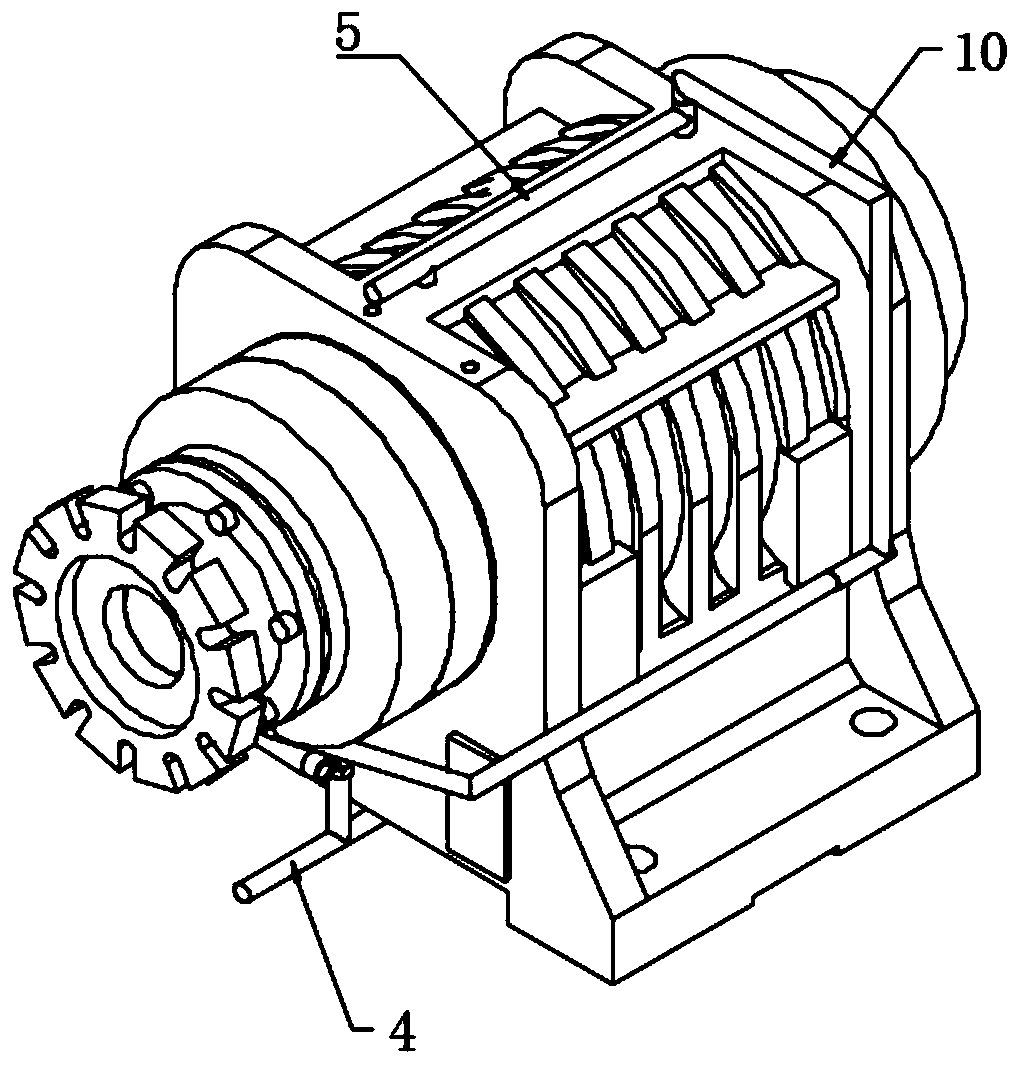

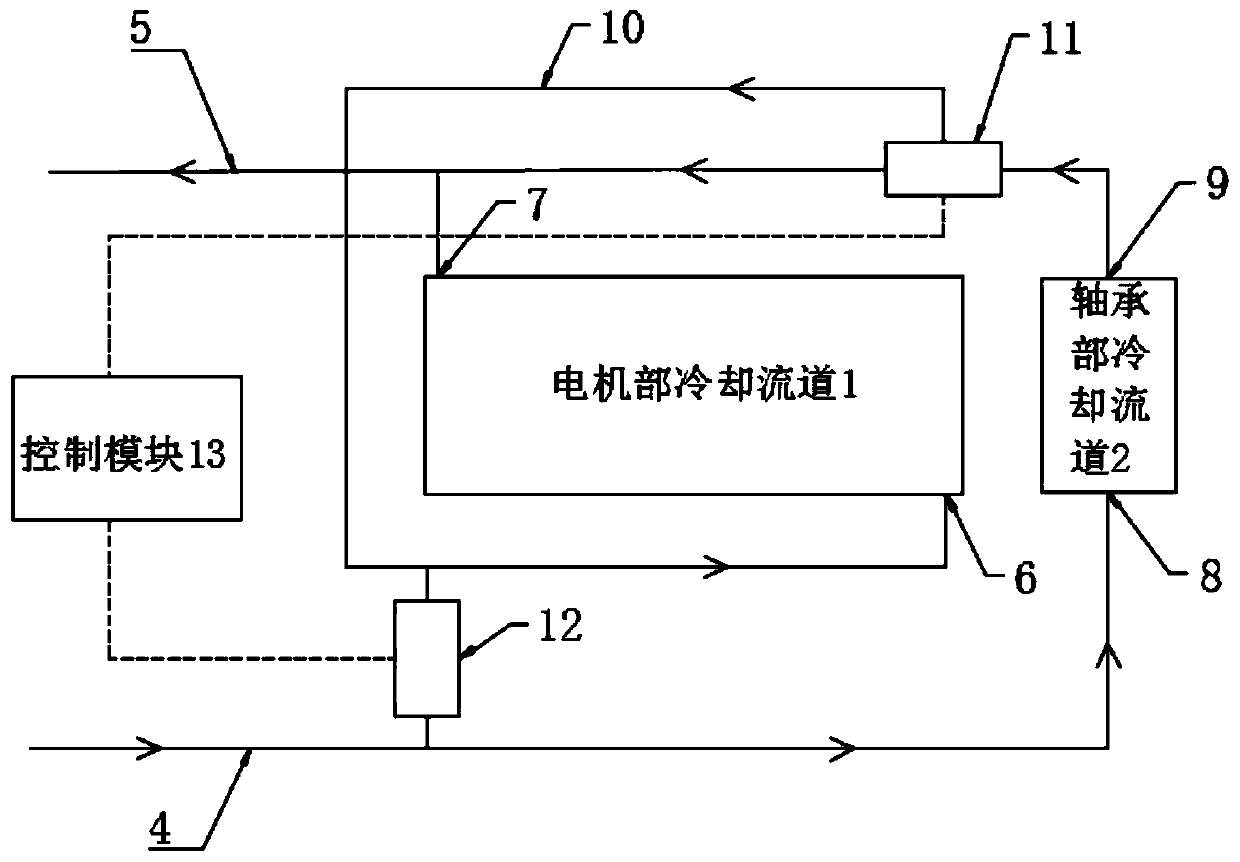

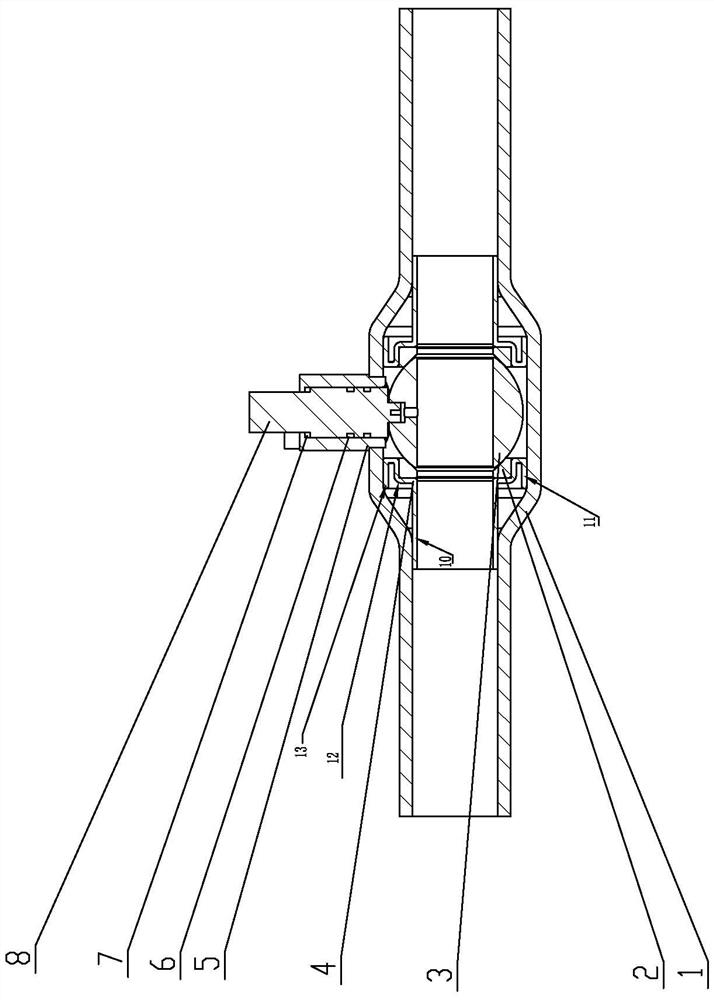

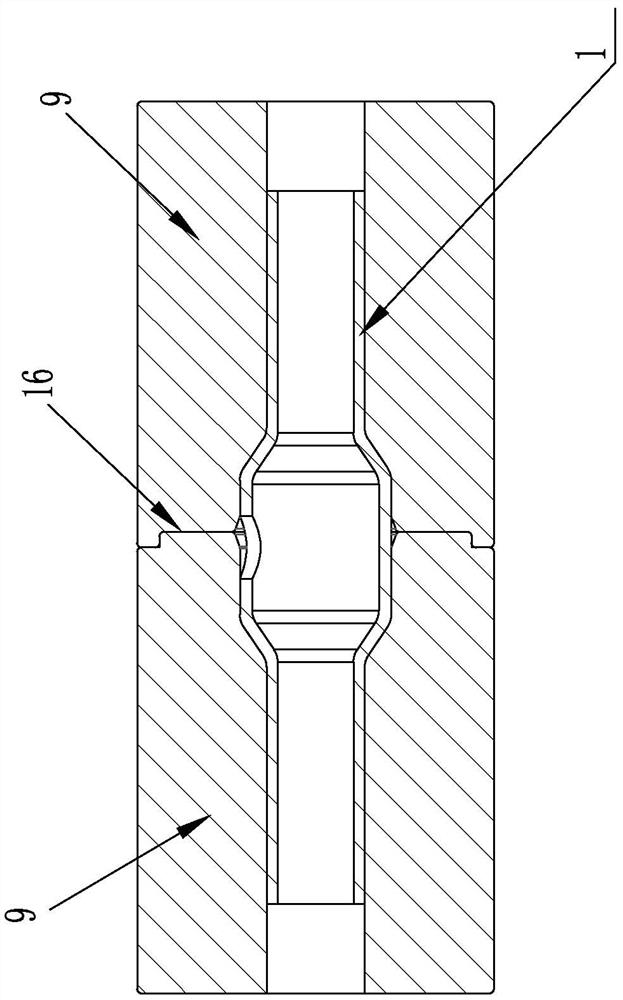

Cooling system, electric spindle and numerical control machine tool

ActiveCN111113143AEasy to reach thermal equilibriumGuaranteed thermal balanceLarge fixed membersMaintainance and safety accessoriesNumerical controlThermodynamics

The invention provides a cooling system, an electric spindle and a numerical control machine tool. The cooling system comprises a motor part cooling flow channel and a bearing part cooling flow channel; a valve pipe assembly is communicated with the motor part cooling flow channel and the bearing part cooling flow channel, and cooling liquid is introduced into the motor part cooling flow channel and the bearing part cooling flow channel by the valve pipe assembly; the valve pipe assembly can control and switch a parallel cooling mode and a series cooling mode; in the parallel cooling mode, cooling liquid flows through the motor part cooling flow channel and the bearing part cooling flow channel at the same time; and in the series cooling mode, the cooling liquid flows through any one of the motor part cooling flow channel and the bearing part cooling flow channel and then flows through the other one. According to the cooling system, the parallel connection mode and the series connection mode are rapidly switched for cooling under the working conditions of different rotating speeds of the electric spindle, the heat productivity is small at a low speed, and heat balance is achieved more rapidly and more easily through the parallel connection mode; and the heat productivity is large at a high speed, the series connection mode with large single-channel flow is adopted, so that theheat balance of a heat source part of the spindle is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

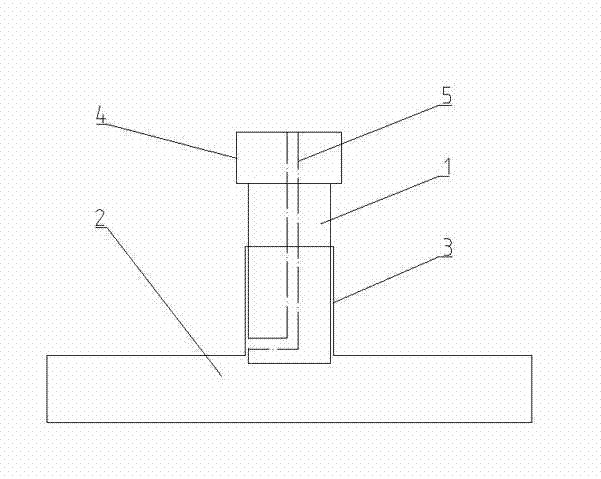

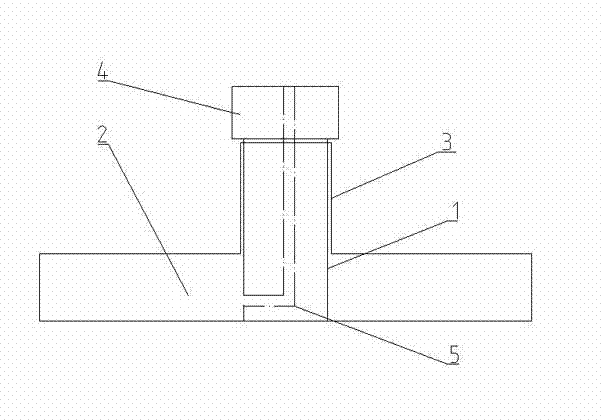

One-time forming method for valve pipe of ball valve body

The invention discloses a one-time forming method for a valve pipe of a ball valve body. The one-time forming method for the valve pipe of the ball valve body is characterized by comprising the following steps: firstly, the outer diameter and the length of a raw material pipe are calculated according to the principle that the material volume is not changed; secondly, an installation hole for installing a valve rod sleeve is machined in the central position of the raw material pipe; thirdly, the machined ball body matched with the drift diameter is filled into the raw material pipe; fourthly, supporting rings used for locating the ball body are additionally arranged at the two ends of the ball body, meanwhile, a sealing seat is additionally arranged between the supporting rings and the ball body, a sealing ring is installed in the sealing seat, and a mold pressing raw material is obtained; fifthly, the two ends of the mold pressing raw material are arranged on a forming mold in a sleeving mode separately, and the forming mold is installed on a pressing machine for pressurization; and finally, the forming mold is moved in the opposite direction, the valve body formed through pressing is taken down, and the valve body and the valve pipe are in transition connection through a frustum body. The method is simple, high in machining efficiency and quality, and capable of reducing the machining cost.

Owner:NANJING JIANGU HIGH & MIDDLE PRESSURE VALVE MFG CO LTD

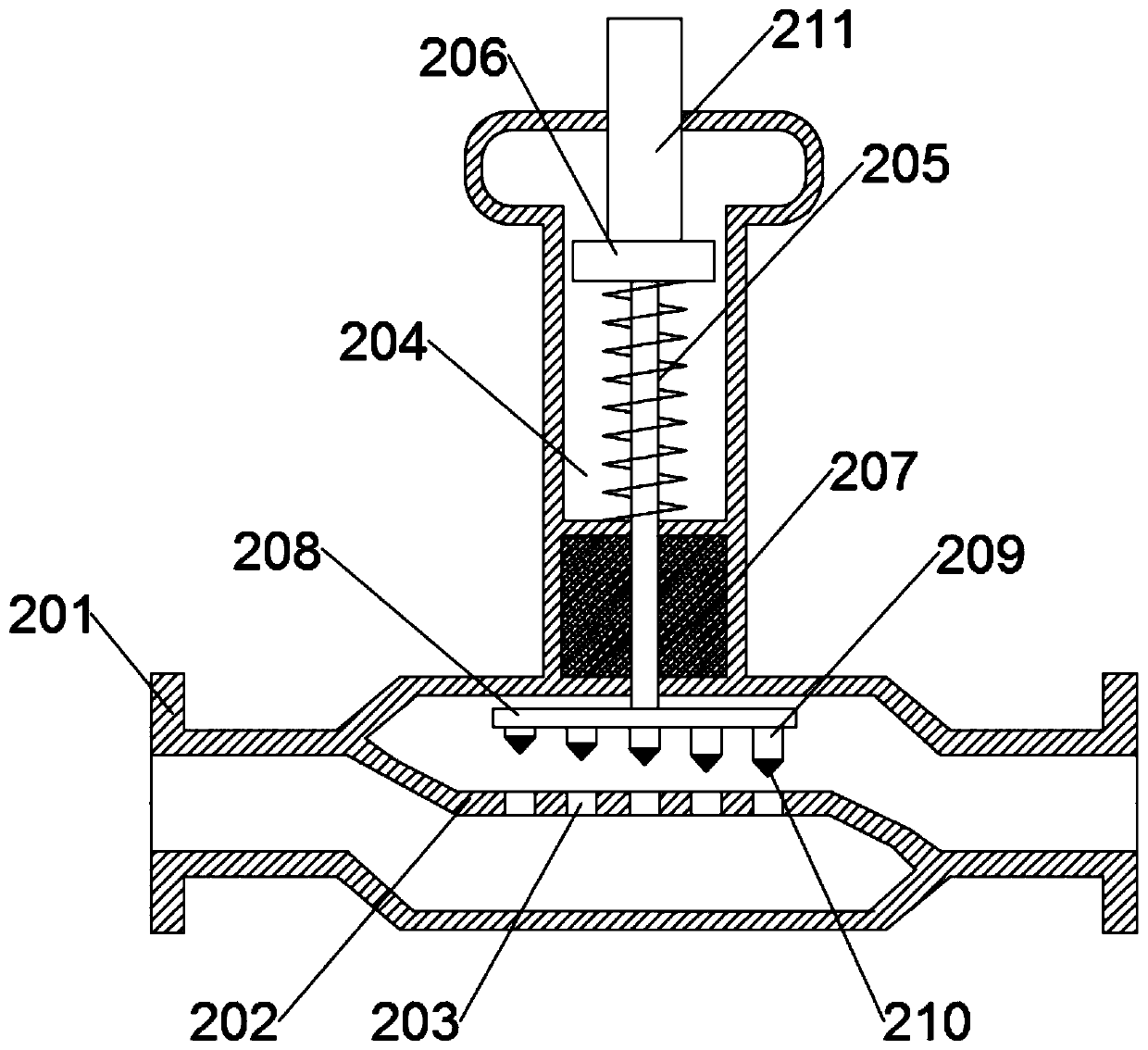

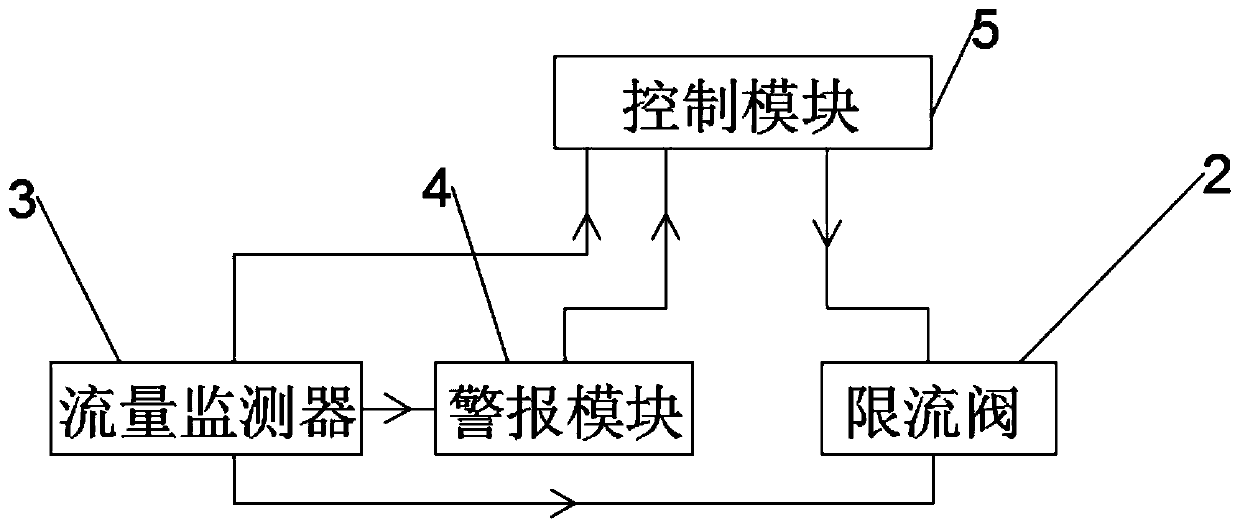

Internet of Things diaphragm gas meter with flow limiting function

ActiveCN111307239AEasy to controlEasy to masterVolume indication and recording devicesApparatus for hiring articlesGas meterEngineering

The embodiment of the invention discloses an Internet of Things diaphragm gas meter with a flow limiting function. The gas meter comprises a flow limiting valve, a flow detector and an alarm device; the flow limiting valve comprises a flow limiting valve pipe; a flow limiting plate is arranged in the middle of the flow limiting valve pipe; an overflowing hole is formed in the flow limiting plate;inlets and outlets are respectively formed in two ends of the flow limiting valve pipe; a driving cavity is formed in the upper end of the flow limiting valve pipe; a push rod is vertically arranged in the driving cavity; the push rod extends into the flow limiting valve pipe; the bottom of the push rod is connected with a push plate; multiple supporting rods are arranged below the push plate. A valve element is arranged at the lower end of each supporting rod; each valve element is located over one corresponding overflowing hole, the supporting rods are different in length, and the valve elements are correspondingly inserted into the overflowing holes in sequence. According to the invention, the gas flow can be detected, when the gas flow is close to or exceeds the maximum flow of a gas meter, the flow is limited through the flow limiting valve, the gas meter is protected, the gas flow is linearly changed in the flow limiting process and is easier to master, and therefore accurate control over the gas flow is achieved.

Owner:重庆明光燃气设备有限公司

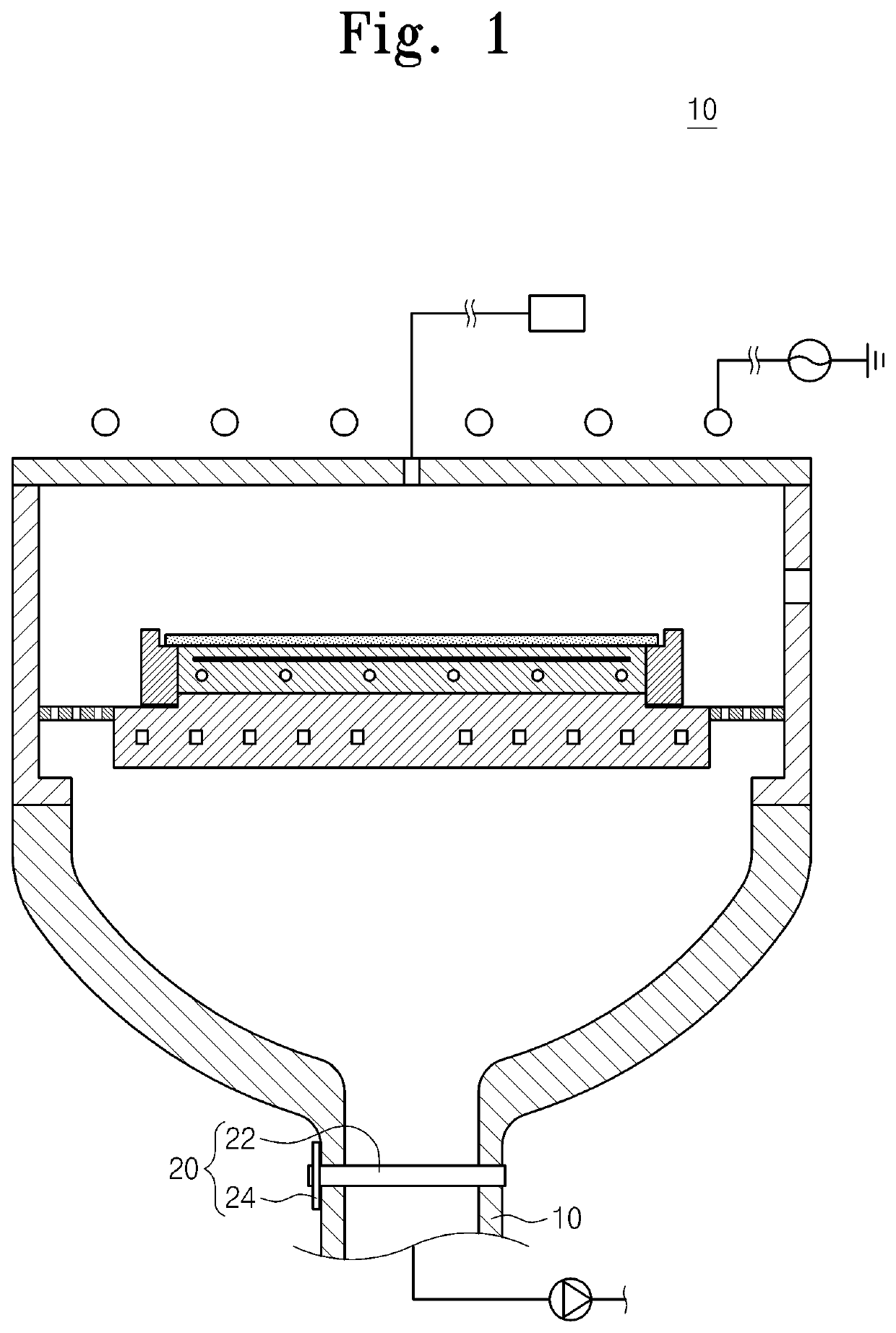

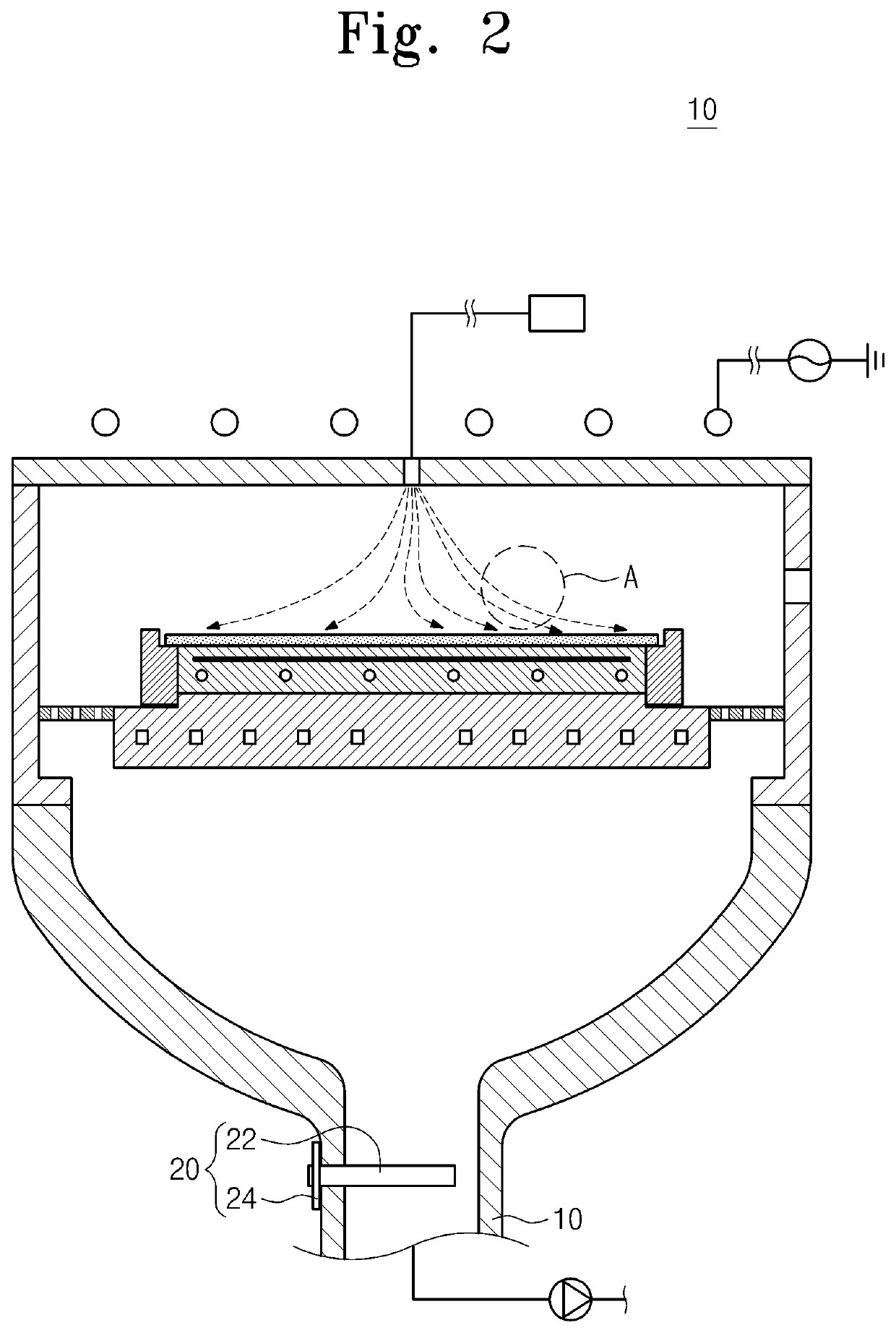

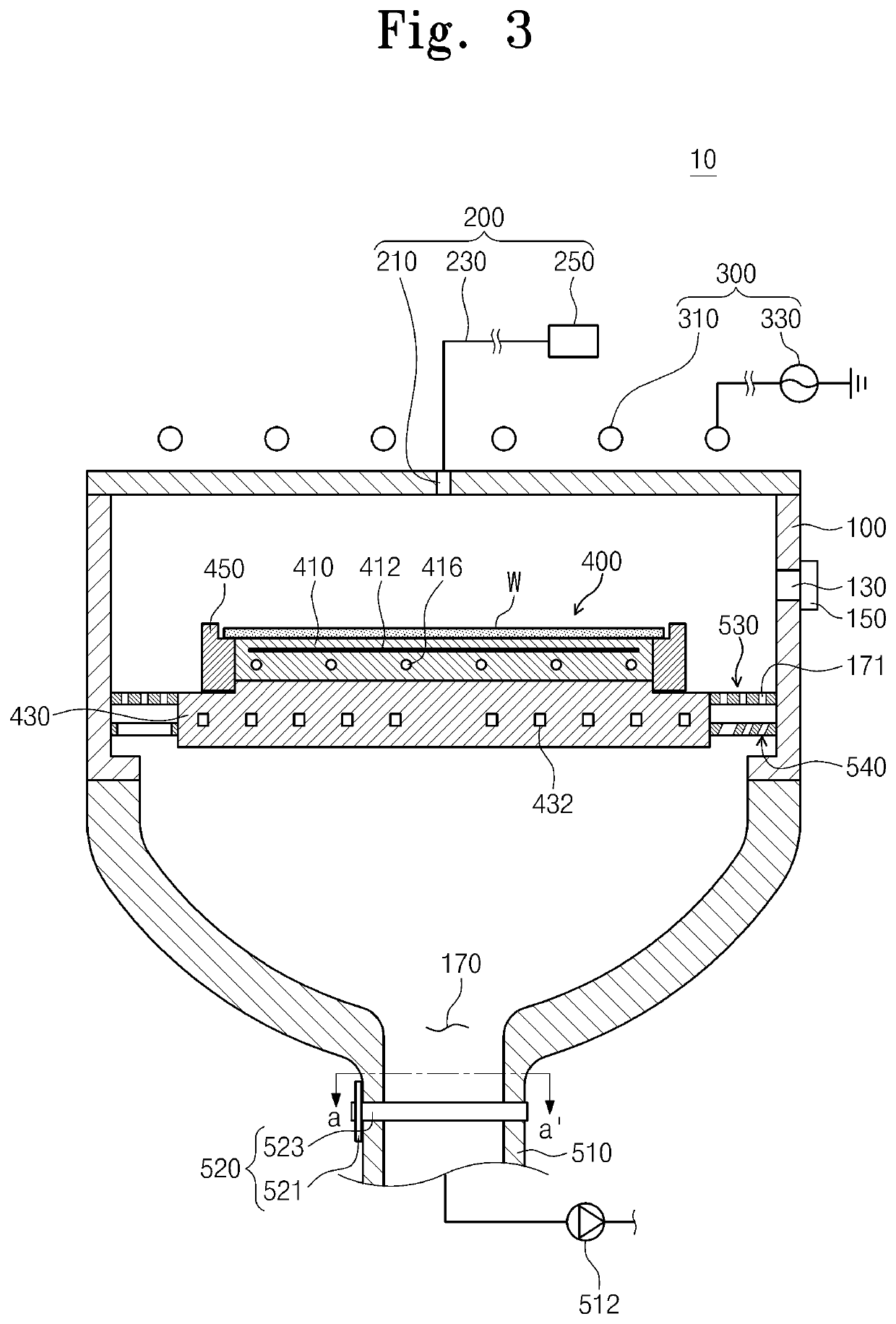

Adjustment plate and apparatus for treating substrate having the same

Provided is a substrate treating apparatus using a process gas and an adjustment plate used thereof. A substrate treating apparatus including a chamber providing a space in which a process is performed, a support member supporting a substrate in the chamber, a gas supply member supplying a process gas onto the substrate disposed on the support member, and an exhaust assembly coupled to the chamber to exhaust a gas in the chamber, wherein the exhaust assembly includes an exhaust pipe connected to the chamber, an exhaust member connected to the exhaust pipe to provide a vacuum pressure in the exhaust pipe, a valve adjusting an opening rate of the exhaust pipe, and an adjustment plate having a cover plate which is provided in the chamber to interfere with a flow of the process gas in an internal region of the chamber in a direction corresponding to, when the exhaust pipe is partially opened, an opened region of the exhaust pipe. Consequently, the process gas may be uniformly supplied onto the substrate.

Owner:SEMES CO LTD

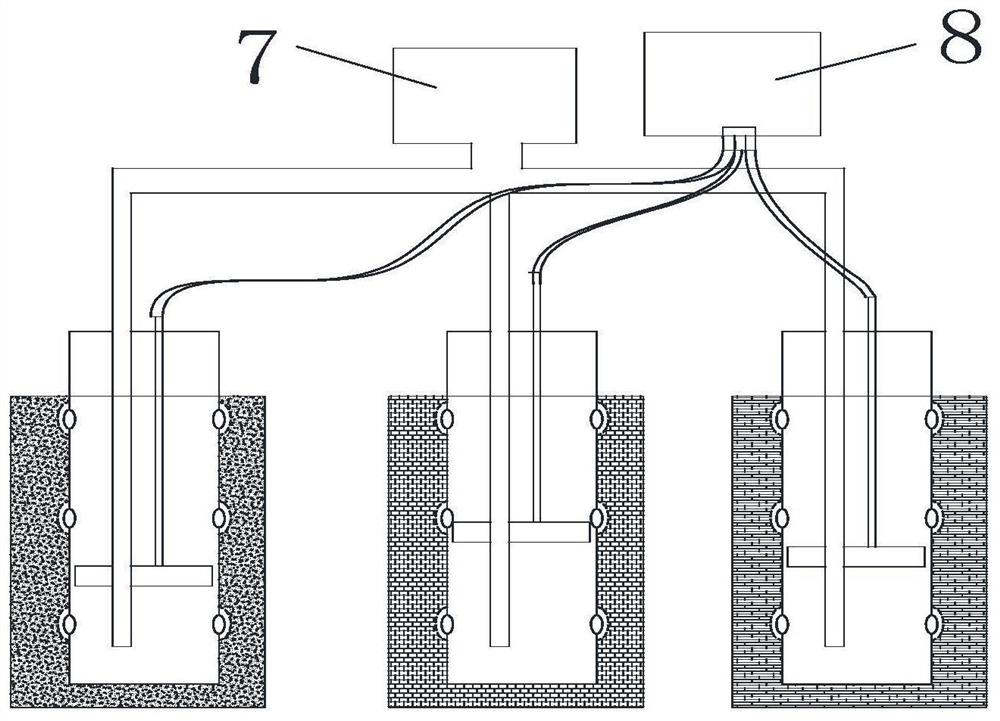

Pressure-adjustable grouting system and grouting method based on special grouting moving cavity

ActiveCN112459069AImprove on-site construction efficiencyAvoid additional drillingBulkheads/pilesSoil preservationClassical mechanicsInjection air

The invention discloses a pressure-adjustable grouting system and grouting method based on a special grouting moving cavity, and relates to the technical field of grouting. The grouting system comprises a main grouting pipe and a plurality of grouting valve pipes connected to the main grouting pipe, wherein each grouting valve pipe is located in an annular space in the wall of a drill hole, each grouting valve pipe comprises a grouting valve pipe body, and a guniting valve port is formed in each grouting valve pipe body; and a grouting pipe, an air injection pipe and a movable piston are arranged in each grouting valve pipe body, the air injection pipes are connected with the movable pistons, air pressure is applied into the movable pistons through the air injection pipes, the movable pistons generate volume expansion after the air pressure is applied, therefore closed cavities are formed between the lower portions of the movable pistons and the grouting valve pipe bodies, and groutingis conducted in the grouting valve pipe bodies according to the positions of the movable pistons. According to the grouting system, pressure adjustment can be conducted on a single grouting valve pipe, so that special grouting is conducted on different target layers, and the on-site construction efficiency can be improved.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +1

Residue-free candle type filtering system

PendingCN111701315AEasy dischargeExhausted completelyStationary filtering element filtersFilter systemCandle

The invention belongs to the technical field of filtering systems, in particular to a residue-free candle filter system. The filtering tank comprises a filtering tank main body, a material tank and aclear liquid tank; a filter bottom cone is arranged at the bottom end of the filter tank main body; the bottom end of the filter bottom cone is communicated with an upper butterfly valve; the bottom end of the upper butterfly valve is communicated with a straight-section pipeline; a bottom auxiliary filter element is connected into the straight-section pipeline in an embedded manner; the bottom end of the straight-section pipeline is communicated with a lower butterfly valve, the lower butterfly valve is communicated with a residue discharging pipe, the material tank is fixedly installed on one side of the filter tank body, the bottom end of the material tank is communicated with a material pump, and an outlet of the material pump is communicated with an inner cavity of the filter bottom cone through a feeding valve pipe. The straight-section pipeline is additionally arranged between the filter bottom cone and the residue discharging valve, the bottom auxiliary filter element embeddedin the straight-section pipeline is used for completely filtering residual liquid, and then the butterfly valve at the lower part is opened, so that residue liquid can be better discharged.

Owner:江苏兴科制药设备制造有限公司

Hydraulic valve with anti-blocking self-dredging mechanism

InactiveCN112343883AAvoid polarizationAvoid cloggingServomotor componentsHollow article cleaningStructural engineeringValved tube

The invention discloses a hydraulic valve with an anti-blocking self-dredging mechanism, and belongs to the technical field of hydraulic valves. The hydraulic valve comprises a hydraulic mechanism, alimiting mechanism sleeves the top of the hydraulic mechanism, the bottom of the limiting mechanism is movably connected with a base through a clamping mechanism, flushing mechanisms are arranged on two sides of the hydraulic mechanism, and one side of the hydraulic mechanism is fixedly connected with an anti-blocking mechanism. According to the hydraulic valve, a filter plate can be driven to rotate around a pin shaft through a second fixing block and push a first fixing block and a piston to move upwards through impact, a telescopic rod extends to drive an extrusion plate to extrude, fix andlimit a first valve pipe and a second valve pipe on the two sides, then polarization of the first valve pipe and the second valve pipe can be avoided, the overall working stability is remarkably improved, noise pollution to the nearby environment is reduced, internal hydraulic oil impurities are prevented from accumulating and blocking an inner cavity of a valve body, the working state stabilityis improved, and use requirements are met.

Owner:杭州伊蓓思电子商务有限公司

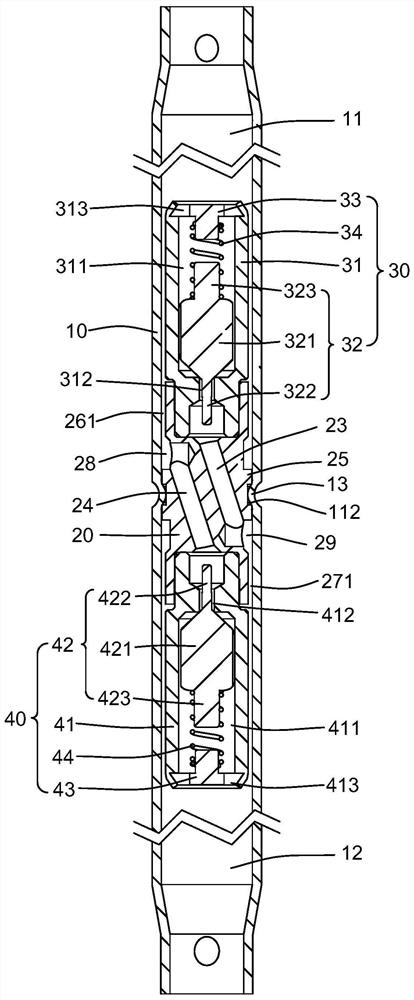

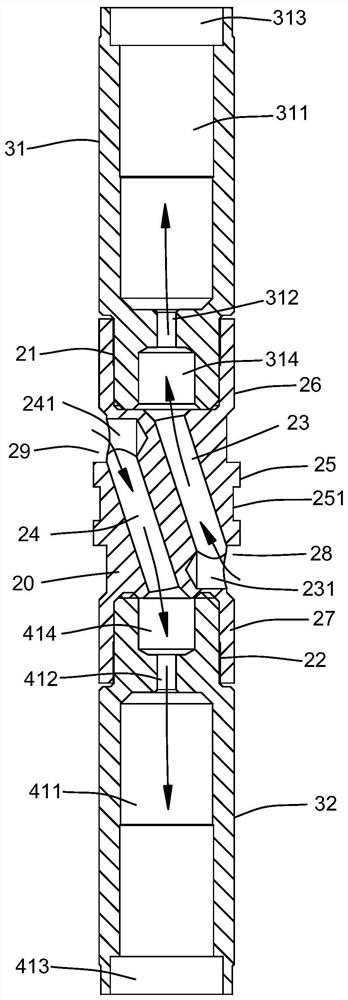

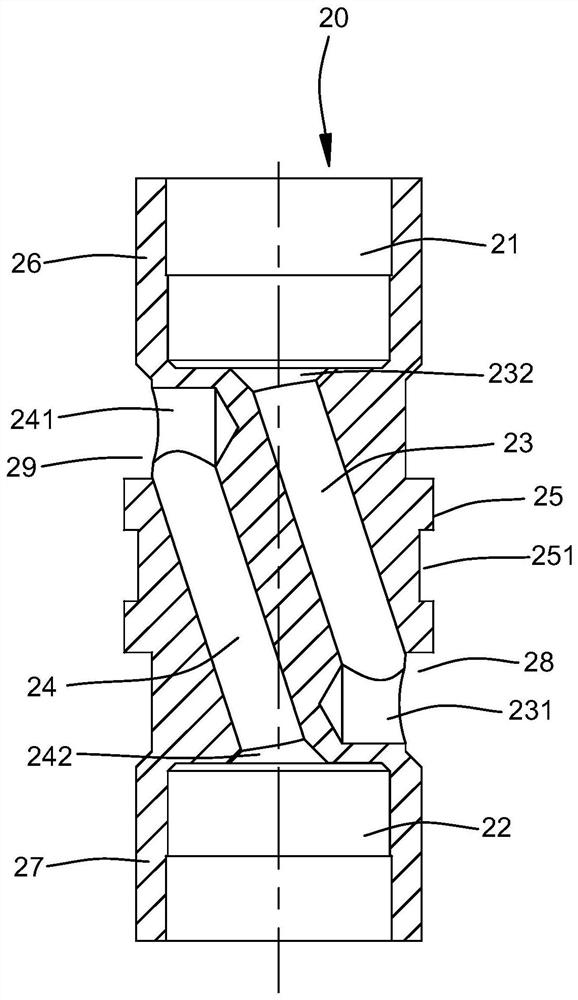

Bidirectional throttle valve

PendingCN111998577AReduce manufacturing costImprove stabilityFluid circulation arrangementValved tubePhysics

The invention relates to a bidirectional throttle valve. The bidirectional throttle valve comprises a valve pipe, a communicating piece, a first valve element assembly and a second valve element assembly. The communicating piece is arranged in the valve pipe and divides the interior of the valve pipe into a first valve cavity and a second valve cavity. The communicating piece is provided with a first cavity, a second cavity, a first channel and a second channel, the first cavity is located in the end, close to the first valve cavity, of the communicating piece, the second cavity is located inthe end, close to the second valve cavity, of the communicating piece, the first channel communicates with the first cavity and the second valve cavity, and the second channel communicates with the second cavity and the first valve cavity. The first valve element assembly is arranged at the first cavity. The second valve element assembly is arranged at the second cavity. The first channel and thesecond channel are both arranged to be linear channels inclined relative to the axial direction of the communicating piece. According to the bidirectional throttle valve, the number of parts is small,the structure is simple, the installation process is very simple, and therefore the production cost of the bidirectional throttle valve is greatly reduced. When fluid flows in the first channel and the second channel, the flow resistance is small, and therefore the stability of the bidirectional throttle valve is better.

Owner:DUNAN ENVIRONMENT TECH

Multi-stage sealing refrigeration valve

ActiveCN113431948AAvoidance of shrinkage leaksImprove the degree of sealingSpindle sealingsOperating means/releasing devices for valvesEngineeringElectric control

The invention relates to the technical field of refrigeration valves, and discloses a multi-stage sealing refrigeration valve which comprises a valve pipe, a partition layer and a valve body. A valve seat is fixedly connected to the middle of the valve pipe, an electric control cavity is formed in the top of the valve seat, an electromagnet is fixedly connected to the top end of an inner cavity of the electric control cavity, and a safety cavity is formed in the center of the bottom of the valve seat. A valve rod is movably connected in the safety cavity in a sleeved mode, an extrusion plate is fixedly connected to the middle of the valve rod, and a magnet is fixedly connected to the bottom end of the valve rod. According to the multi-stage sealing refrigeration valve, through the designed valve rod, a limiting ring and a sealing ring II, when the refrigeration valve operates and the valve rod is lifted up, the limiting ring can be extruded through the extrusion plate, so that the sealing ring II is extruded and stretched, the sealing ring II is not affected by thermal expansion and cold contraction, the sealing ring II is tightly attached to the valve rod, the extrusion plate is tightly attached to the limiting ring, and therefore the situation of cold contraction leakage caused by the fact that cold media influence all parts in the operation process of the refrigeration valve is avoided.

Owner:徐州金宸制冷设备有限公司

Boosting type dense-phase conveying system

ActiveCN114180345ASpeed up moldingImprove molding efficiencyBulk conveyorsControl engineeringAir pump

The invention discloses a boosting type dense-phase conveying system which comprises a boosting material guide pipe, a pulse material column separation cabin, an adjustable guide mechanism and a pulse air knife generator, the adjustable guide mechanism and the pulse air knife generator are located in the boosting material guide pipe and the pulse material column separation cabin, and a pneumatic boosting mechanism is arranged on the outer side of the boosting material guide pipe. One end of the boosting material guide pipe is fixedly connected with the end part of the pulse material column separation cabin, the other end of the boosting material guide pipe and the other end of the pulse material column separation cabin are respectively provided with an inlet electric control valve and a material plug electric control valve, and the input end of the pneumatic boosting mechanism is fixedly connected with a boosting air pump mechanism. According to the material plug forming device, a novel boosting structure is additionally arranged, dense-phase conveying airflow is intervened and accelerated through boosting valve pipe structures evenly distributed on the surface of the boosting material guide pipe, dense-phase conveying is accelerated and boosted through boosting gas introduced from the outside, and the material plug forming speed and the dense-phase conveying efficiency are improved.

Owner:厦门安麦信自动化科技有限公司

Digital water timer

ActiveUS20210105959A1Easy to operateEasy to displayOperating means/releasing devices for valvesStatic indicating devicesEngineeringHydrology

A digital water timer may include a main body, a water valve, a locating base, a driving base, and a timer. The main body has a water inlet and a water outlet, and a valve tube protrudes from a lateral side of the main body. The water valve connected to the main body is controlled by the timer to achieve on / off operation of channels inside the main body. The locating base is secured on the main body, and the driving base is adapted to have rotation relative to the locating base and be secured at a specific position after rotated. The timer installed in the driving base comprises a display panel and an operation interface which are exposed externally for operation. The driving base with the timer is rotated relative to the locating base, and the display panel is adjusted as needed to provide an optimal view for operation.

Owner:SHIN TAI SPURT WATER OF THE GARDEN TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com