Control valve used for dust removing system

A technology of dust removal system and control valve, applied in the direction of removing smoke, lift valve, valve details, etc., can solve the problem of no control valve, etc., and achieve the effect of convenient operation, reasonable design and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

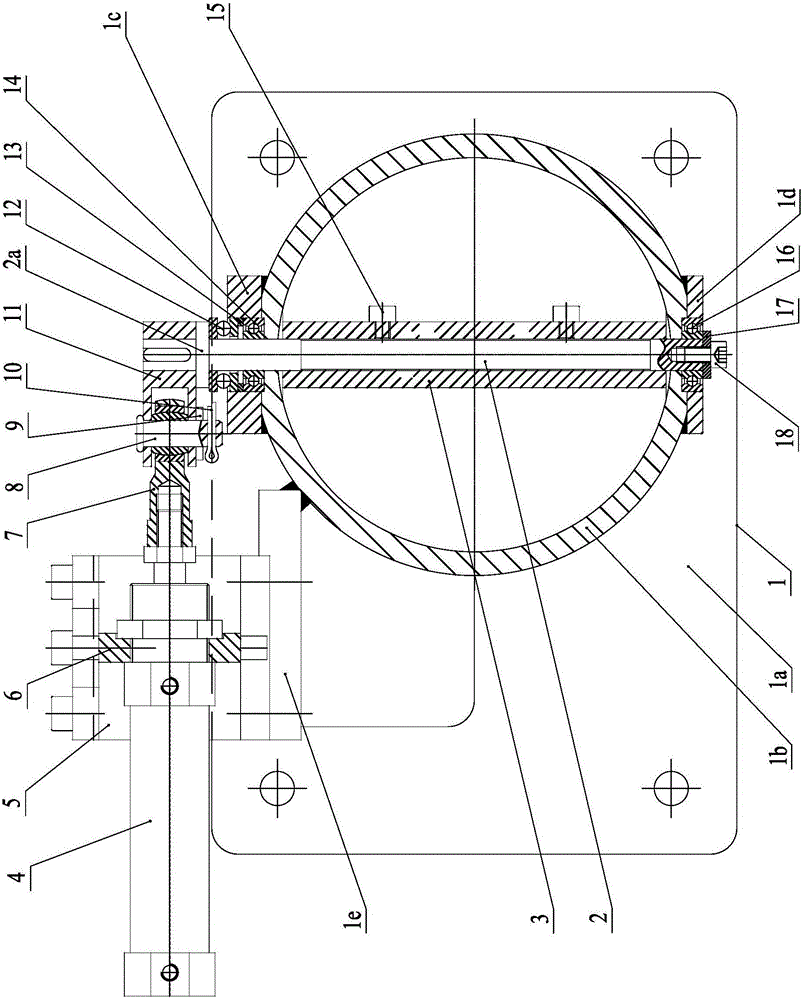

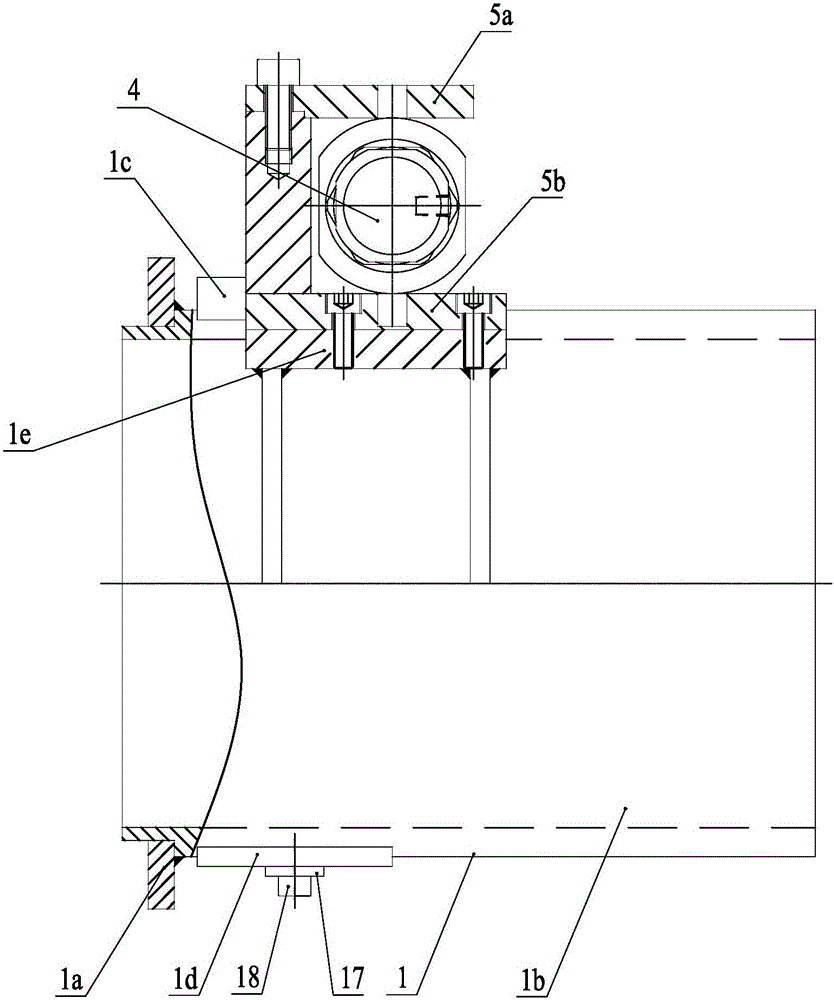

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0015] As shown in the figure: the control valve for the dust removal system in the embodiment is mainly composed of a valve seat 1, a rotating shaft 2, a butterfly door 3, a crank 11 and a swing driving mechanism. The valve seat 1 includes a seat plate 1a and a valve Pipe 1b, the seat plate 1a is provided with a fixed installation hole; the rotating shaft 2 is vertically arranged and radially penetrates the valve pipe 1b, the upper end of the rotating shaft 2 is supported on the top of the valve pipe 1b through the upper bearing assembly, and the lower end of the rotating shaft 2 is passed through the lower bearing The assembly is supported at the bottom of the valve tube 1b; the butterfly gate 3 is set in the valve tube 1b, the shape and size of the butterfly gate 3 matches the valve tube 1b, the butterfly gate 3 is installed on the rotating shaft 2 and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com