Valve body moving type on-off valve for industrial pipelines

An industrial pipeline and mobile technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve serious, unstable quality, pollution and other problems, and achieve the effects of small flow resistance, reliable and stable quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

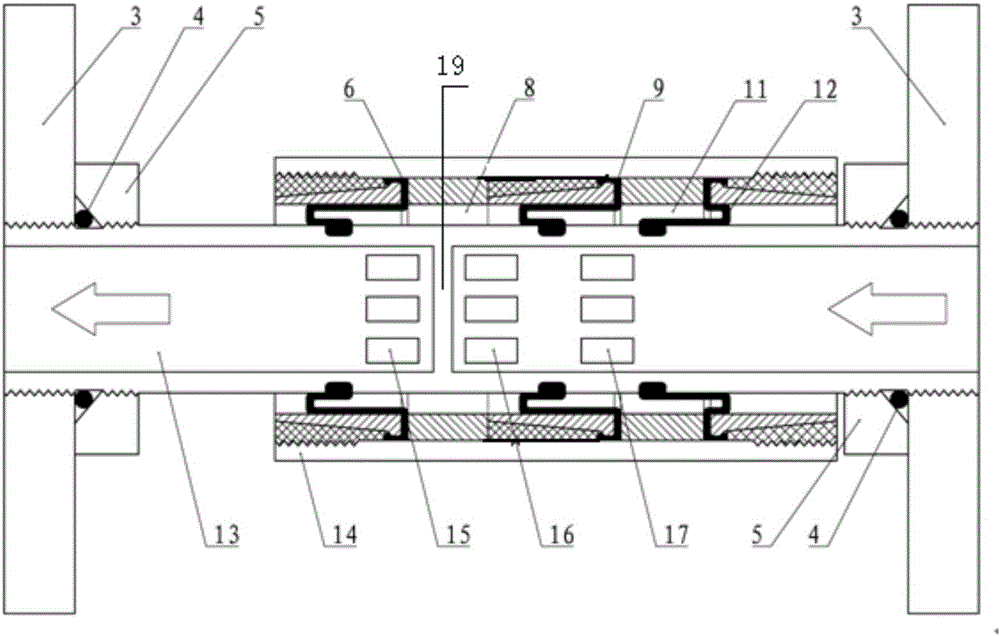

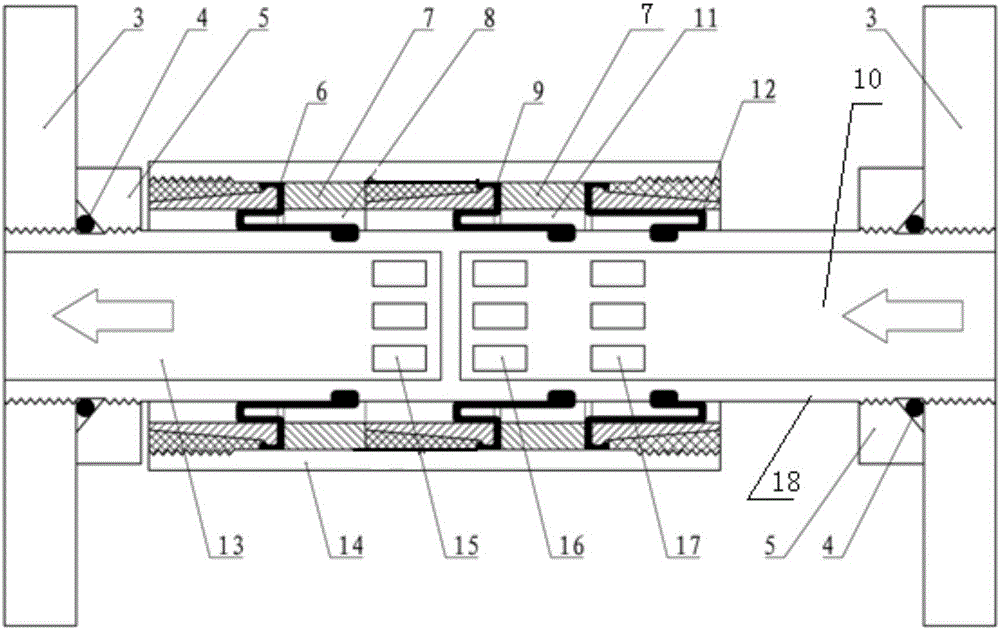

[0018] Take a section of round pipe that matches the diameter of the industrial pipeline as the inner valve pipe 18, and the pipe ports at both ends are respectively used as the input port 10 and the output port 13 of the valve. The middle section of the inner valve pipe 18 is provided with a partition 19, and the inner valve pipe 18 is divided There are two sections, respectively an input section and an output section, the output section is provided with an output valve hole 15, and the input section is provided with an input valve hole 16 and a balance hole 17, such as figure 1 , 2 shown. The inner edges of the three sealing rubber sleeves are respectively socketed in corresponding fixing grooves on the outer wall of the inner valve tube 18 . From the end of the outer valve tube 14, insert the inner cone pressure ring 1, the outer cone pressure ring 2, and the positioning pressure ring 7 with threaded buckles respectively, and assemble them in sequence, as shown in FIG. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com