Tunnel ground surface directional large-diameter deep hole grouting device and grouting method

A grouting device and large-diameter technology, which is applied in tunnels, tunnel linings, excavations, etc., can solve the problems of long time consumption and high hidden costs, and achieve the effects of improving stability, reducing grouting difficulty, and increasing grouting reinforcement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

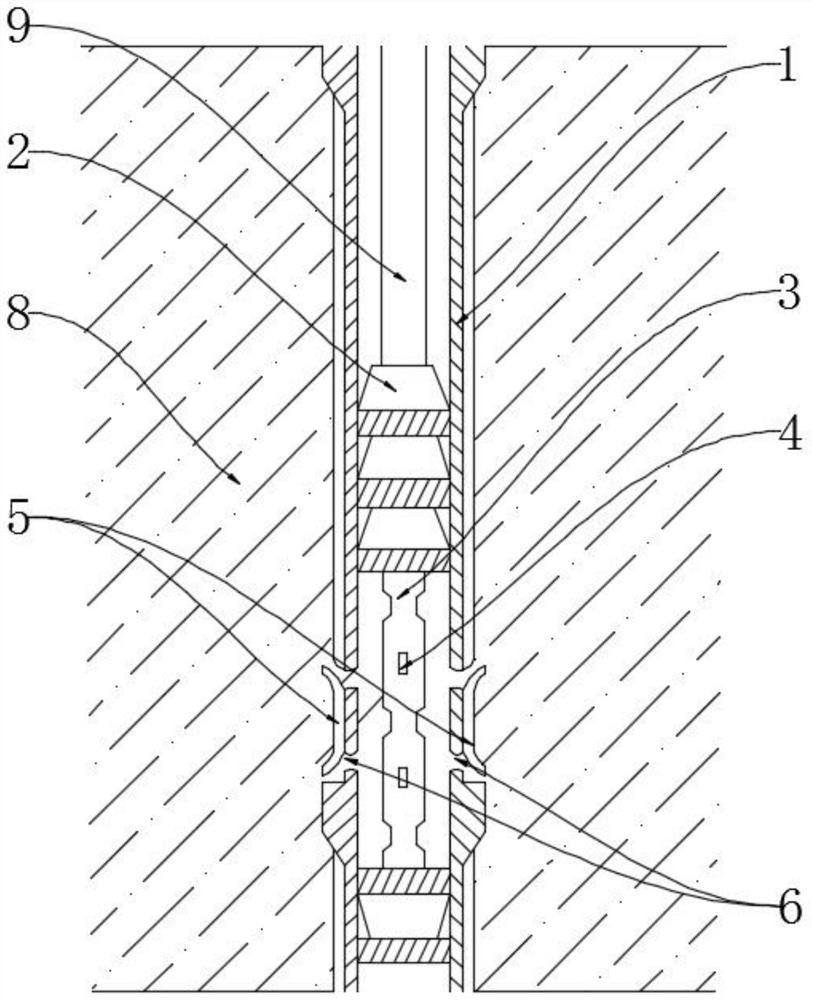

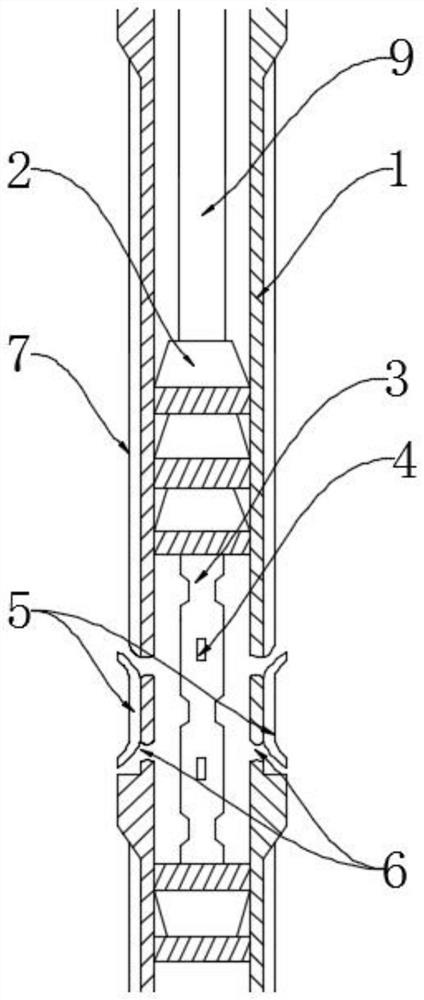

[0068] see figure 1 and figure 2 , the present embodiment provides a directional large-diameter deep hole grouting device on the surface of the tunnel, including: a base layer 8, and a grouting channel is drilled on the base layer 8;

[0069] A sleeve 7, the sleeve 7 is inserted into the grouting channel;

[0070] A plastic valve tube 1, the plastic valve tube 1 is inserted into the sleeve 7, and the outer surface of the plastic valve tube 1 is attached to the inner wall of the sleeve 7;

[0071] A slurry outlet 6, the slurry outlet 6 is arranged on the plastic valve tube 1;

[0072] A rubber one-way valve 5, the rubber one-way valve 5 is arranged on the sleeve 7;

[0073] A grouting core tube 3, the grouting core tube 3 is arranged in the plastic valve tube 1, and the grouting core tube 3 is provided with a grouting port 4;

[0074] Grouting pipe 9, one end of the grouting pipe 9 communicates with the slurry core pipe 3, and the sealing ring 2 is sleeved on the outside o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com