Pressure-adjustable grouting system and grouting method based on special grouting moving cavity

A technology of grouting system and grouting pressure, which is applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as delaying construction period, increasing project construction cost, and increasing the number of grouting pipes, so as to avoid additional drilling , Improving the efficiency of on-site construction and saving the cost of engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

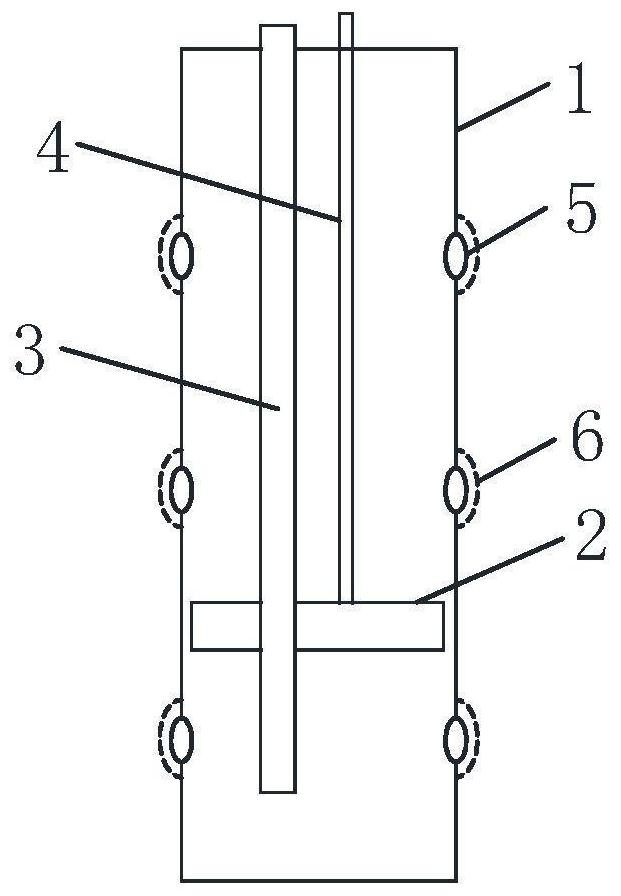

[0039]When it is necessary to apply different pressures to a single grouting valve tube, the movable piston and the grouting valve tube body generate closed cavities of different depths to realize multi-layer grouting in a single grouting valve tube, each layer can be According to the geological conditions, different grouting pressures are designed for the grouting depth, so that the present invention can carry out special grouting on the target soil layer, realize multi-layer grouting with a single pipe, and improve the efficiency of on-site construction.

[0040] The specific grouting method is:

[0041] The first step is to design the position of the spraying valve port according to the geological conditions;

[0042] The second step is to set out the line on site, determine the position of the grouting valve pipe and drill the well through the drilling machine;

[0043] The third step is to install the grouting valve pipe body, and place the movable piston, grouting pipe,...

Embodiment 2

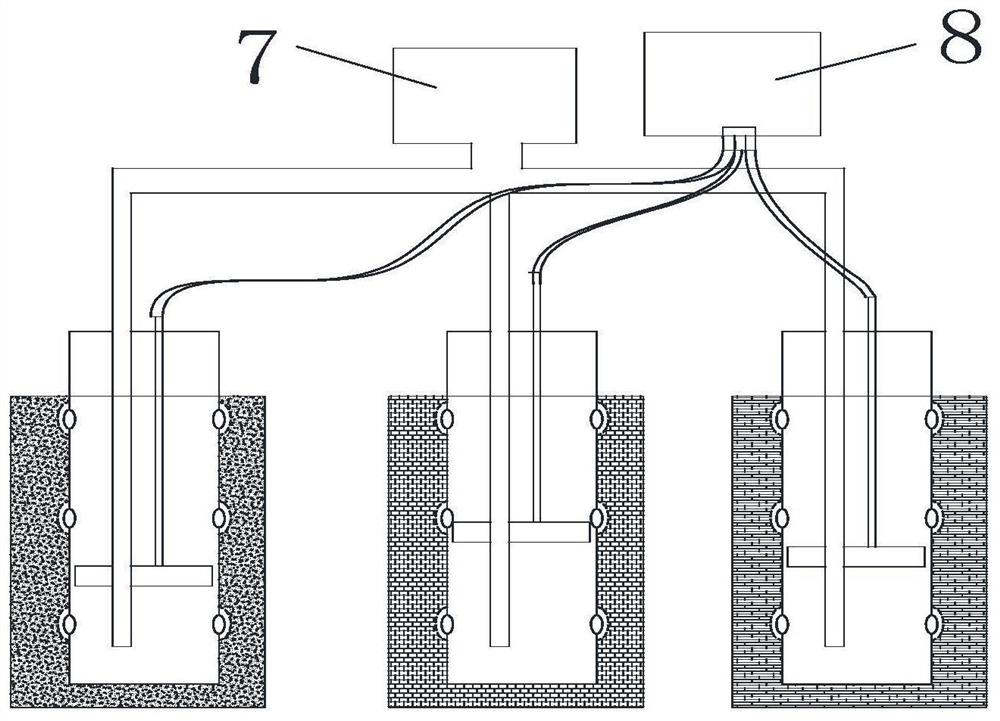

[0050] like figure 2 As shown, when the grouting system is used in different formations such as sand layers and soil layers, different pressures need to be applied to different grouting valve pipes. At this time, the movable piston and each grouting valve pipe body generate Grouting is performed on each grouting valve pipe by means of closed cavities of different depths.

[0051] The specific grouting method is:

[0052] The first step is to design the position of the spraying valve port according to the geological conditions;

[0053] The second step is to set out the line on site, determine the position of the grouting valve pipe and drill the well through the drilling machine;

[0054] The third step is to install the grouting valve pipe body, and place the movable piston, grouting pipe, and gas injection pipe in the grouting valve pipe body according to the design of the present invention

[0055] The fourth step is to confirm the grouting position of each grouting val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com