One-time forming method for valve pipe of ball valve body

A valve body and valve tube technology, applied in the direction of metal extrusion dies, etc., can solve problems such as difficult to guarantee weld quality, difficult to reduce costs, complex processing technology of small diameter ball valve body, etc., to improve the compressive strength and consistency Sexuality and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

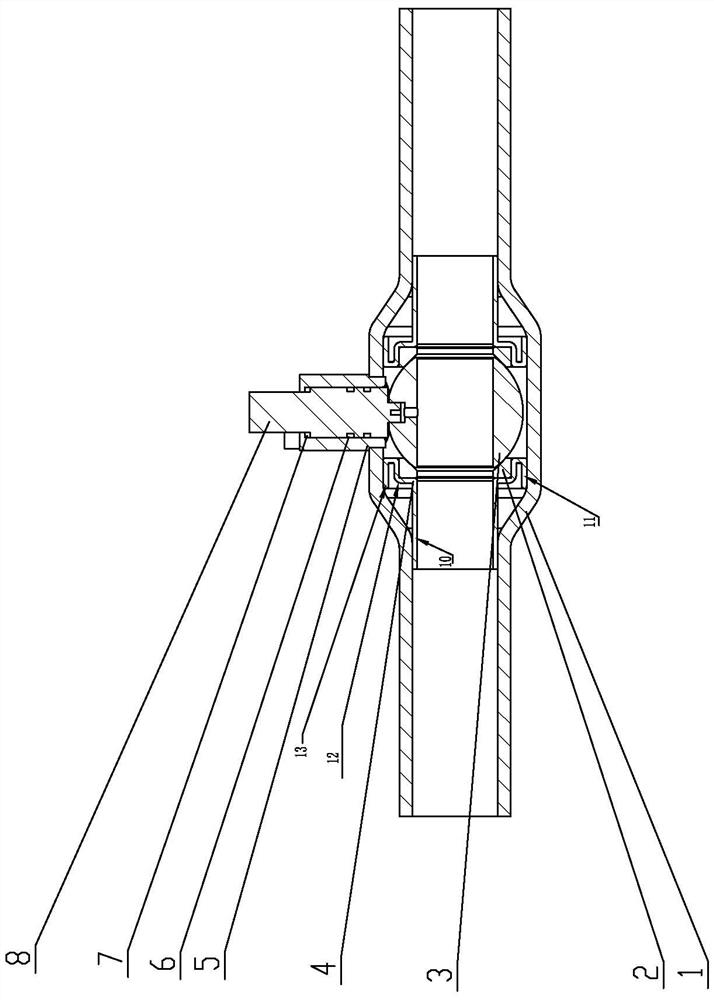

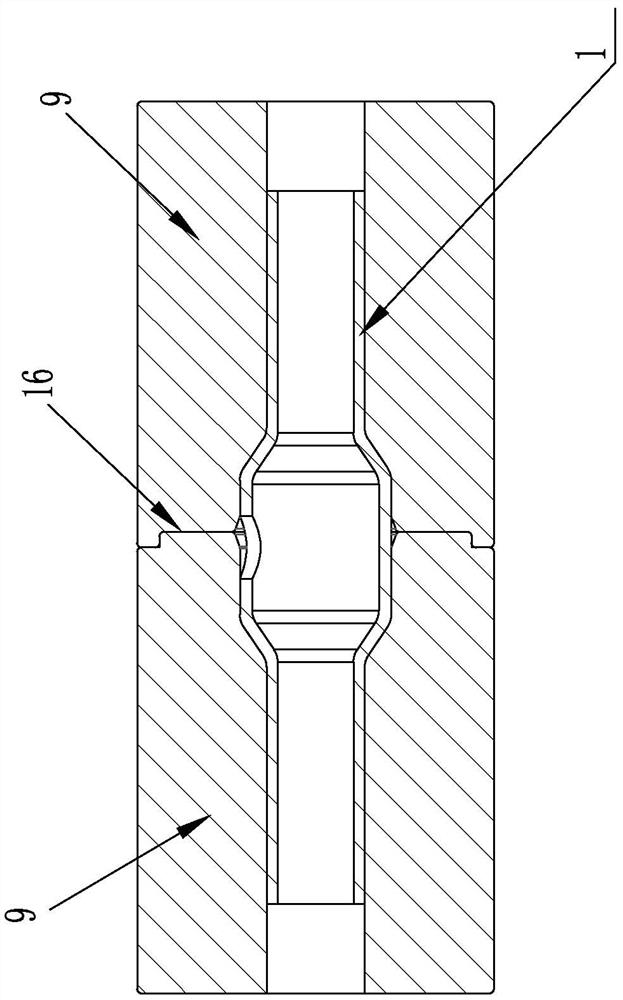

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Such as Figure 1-2 shown.

[0025] A method for one-time forming of a valve body and valve tube of a ball valve, comprising the following steps:

[0026] First of all, according to the principle of constant material volume, according to the diameter of the final formed valve (that is, the inner diameter of the valve tube, generally less than 50mm, when it exceeds 50mm, the requirements for the press and molding die are higher, and if conditions permit, it can also be used. One-time molding) and the length of the valve tube to calculate the outer diameter and length of the raw material tube;

[0027] Secondly, a mounting hole for installing the valve stem sleeve 5 is processed at the central position of the raw material pipe. During specific implementation, the mounting hole can also be processed and formed after forming;

[0028] Third, put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com