Structure for increasing negative pressure

A technology of negative pressure and air compressor, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low centrifugal force, high pressure, insufficient suction, etc., and achieve the effect of increasing the suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

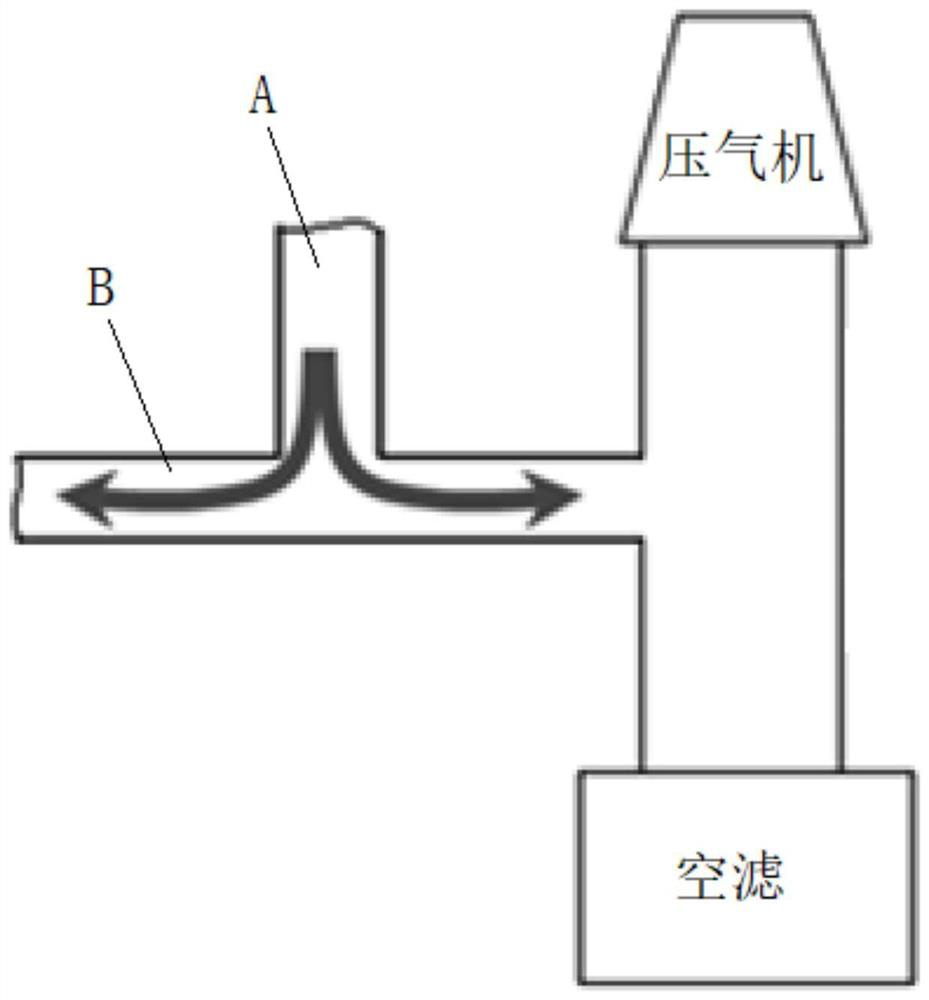

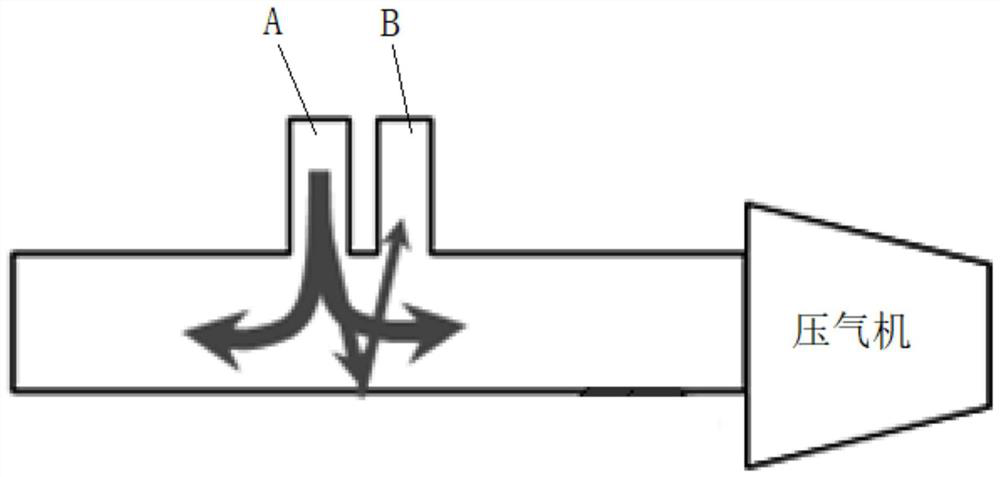

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The oil-gas separation mechanism 3 is an oil-gas separator of model H100-140, which has a simple structure and is easy to install.

Embodiment 2

[0026] The oil-gas separation mechanism 3 is an air-driven oil-gas separator, the compressed air inlet end of the air-driven oil-gas separator is connected to the automobile gas tank or the air inlet 6 at the rear end of the compressor 5 through the air pipe 9, and the oil outlet end of the air-driven oil-gas separator The oil return pipe 10 is connected to the engine, and the compressed air drives the oil-air separation filter element to rotate at high speed, which is beneficial to increase the negative pressure in the closed cycle crankcase 1 .

Embodiment 3

[0028] The oil-gas separation mechanism 3 is an oil-drive oil-gas separator, the oil inlet end of the oil-drive oil-gas separator is connected to the high-pressure oil main oil passage of the engine, the oil-drive oil-gas separator is installed on the engine body, and the filtered oil of the oil-drive oil-gas separator flows directly Back to the engine, the high-pressure engine oil drives the oil-gas separation filter element to rotate at a high speed, which is conducive to increasing the negative pressure in the closed cycle crankcase 1.

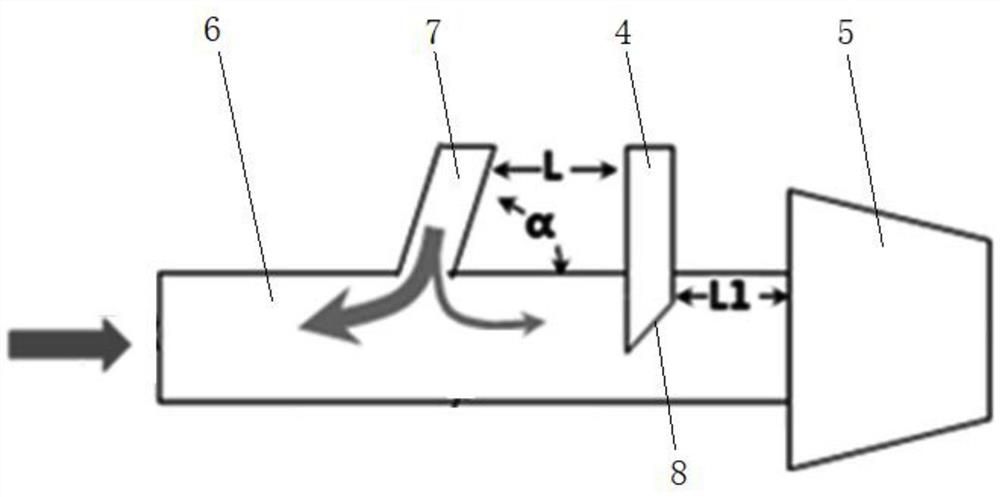

[0029] In the present invention, the distance between the ventilation pipe and the compressor is set to be smaller than the distance between the ventilation pipe and the anti-surge valve pipe, and one end of the ventilation pipe extends obliquely toward the direction of the compressor or is provided with a first oblique cut facing the compressor. It can slow down the impact of the anti-surge pipe airflow on the ventilation pipe, increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com