Horizontal positioning grouting reinforcement construction process suitable for municipal construction muddy soft soil stratum

A muddy soft soil, horizontal positioning technology, applied in directional drilling, earthwork drilling, drilling equipment, etc., can solve problems such as ballast bed and segment separation, high formation loss rate, tunnel water leakage, etc., to reduce formation High loss rate, high seed setting rate, and short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

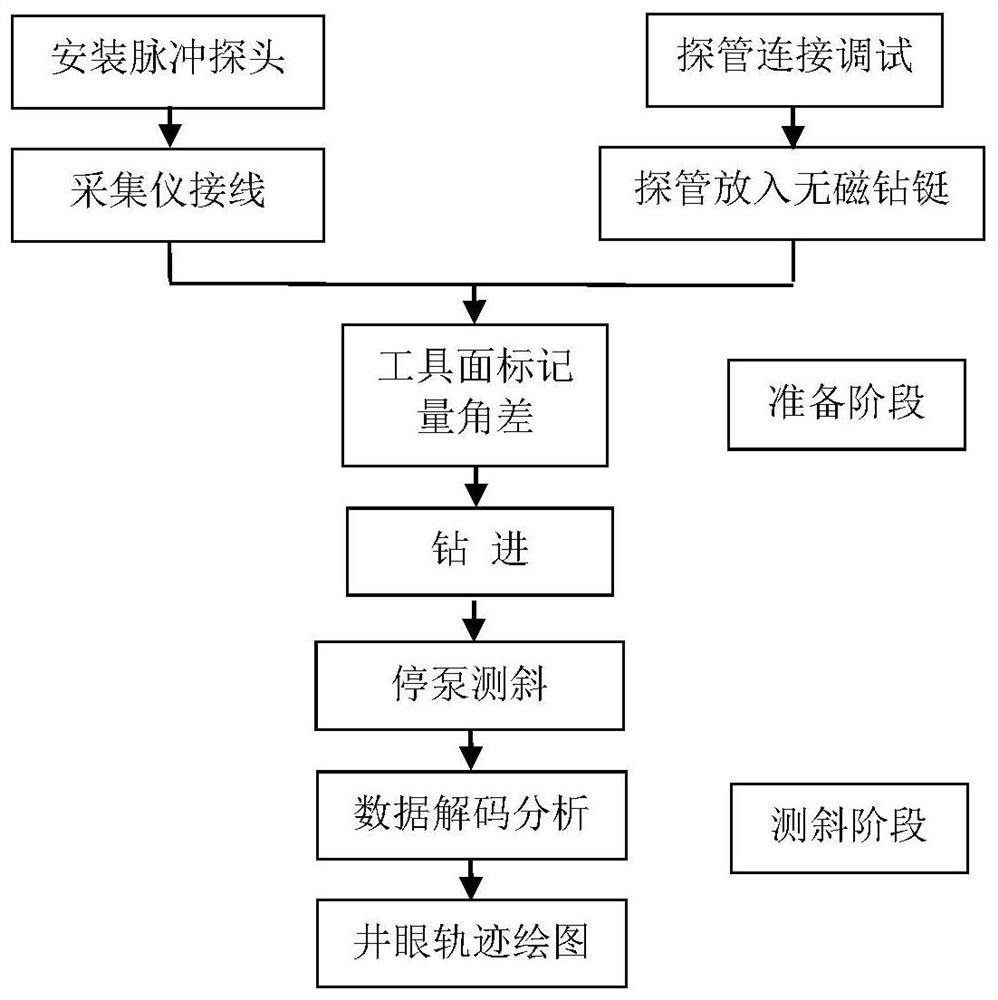

[0048] 1. Construction technology of horizontal positioning grouting reinforcement in silty soft soil strata

[0049] The horizontal positioning grouting reinforcement construction technology of the silty soft soil stratum of the present embodiment specifically includes the following steps:

[0050] Step A: Arrange drilling equipment on the ground or in the construction well, and select the opening angle according to the distance between the opening point and the target point;

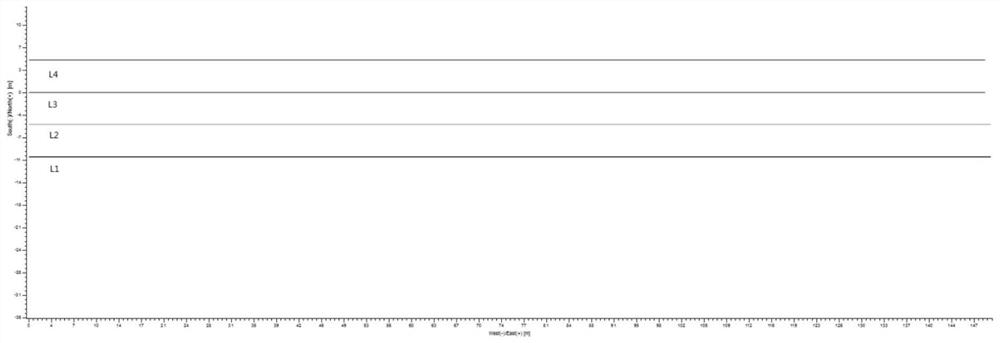

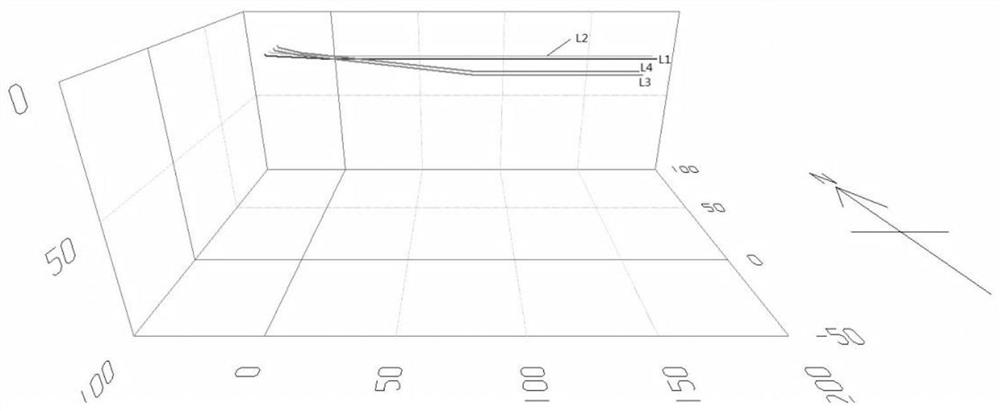

[0051] Step B: using directional drilling technology to construct a borehole in the middle of the muddy soft soil layer, and the drill hole consists of a deflection section borehole and a horizontal section borehole;

[0052] Step C: After the drilling construction is completed, install the grouting casing and the grouting valve pipe in the drilling;

[0053] Step D: Inject grouting material into the silty soft soil formation through drilling for reinforcement.

[0054] The technical solution of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com