A car front floor central channel structure

A technology for the front floor and central passage of a car, which is applied to the upper structure, upper structure sub-assembly, vehicle components, etc., and can solve the problems of increasing the weight of the car body, increasing the difficulty of welding the front floor, and increasing the number of welding parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

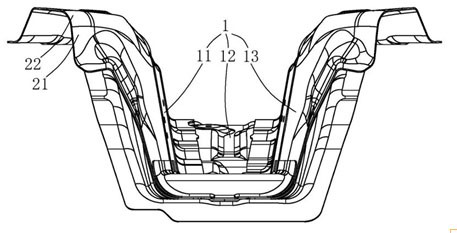

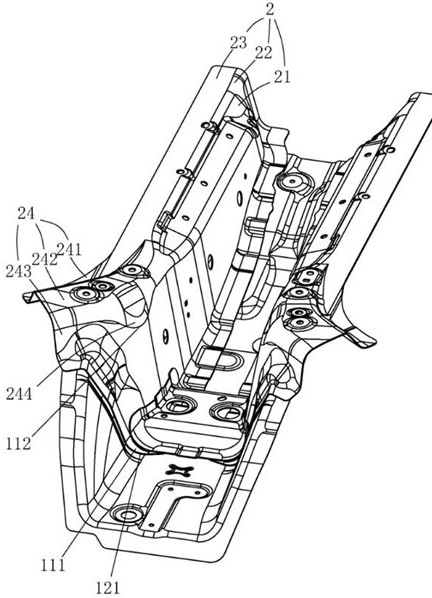

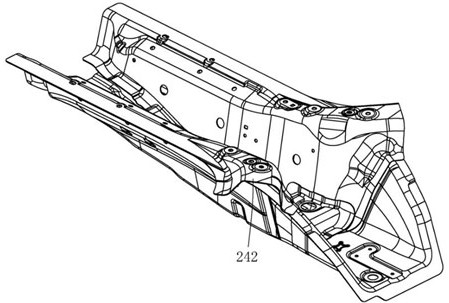

[0031] refer to figure 1 , which is a car front floor central channel structure disclosed by the present invention, combined with figure 1 and figure 2 As shown, it includes an inverted U-shaped central channel body 1, and also includes reinforcing components 2 that are symmetrically fixedly connected to both sides of the opening edge of the central channel body 1. The reinforcing component 2 includes a first The reinforcing plate 21 and the first reinforcing arc plate 22 are fixedly connected to the end of the first reinforcing plate 21 away from the opening of the central channel body 1 . The inverted U-shaped central channel body 1 itself can improve the impact deformation resistance in the longitudinal direction, and by increasing the rigidity under the side impact on the first reinforcement plate 21, the first reinforcement arc plate 22 can absorb the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap