Rocket engine support

A rocket engine and engine technology, which is applied to the frame of the engine, projectiles, supporting machines, etc., can solve problems such as broken bracket connection parts, impact on rocket operation, and increased bracket weight, so as to increase structural rigidity, reduce weight, and increase structure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

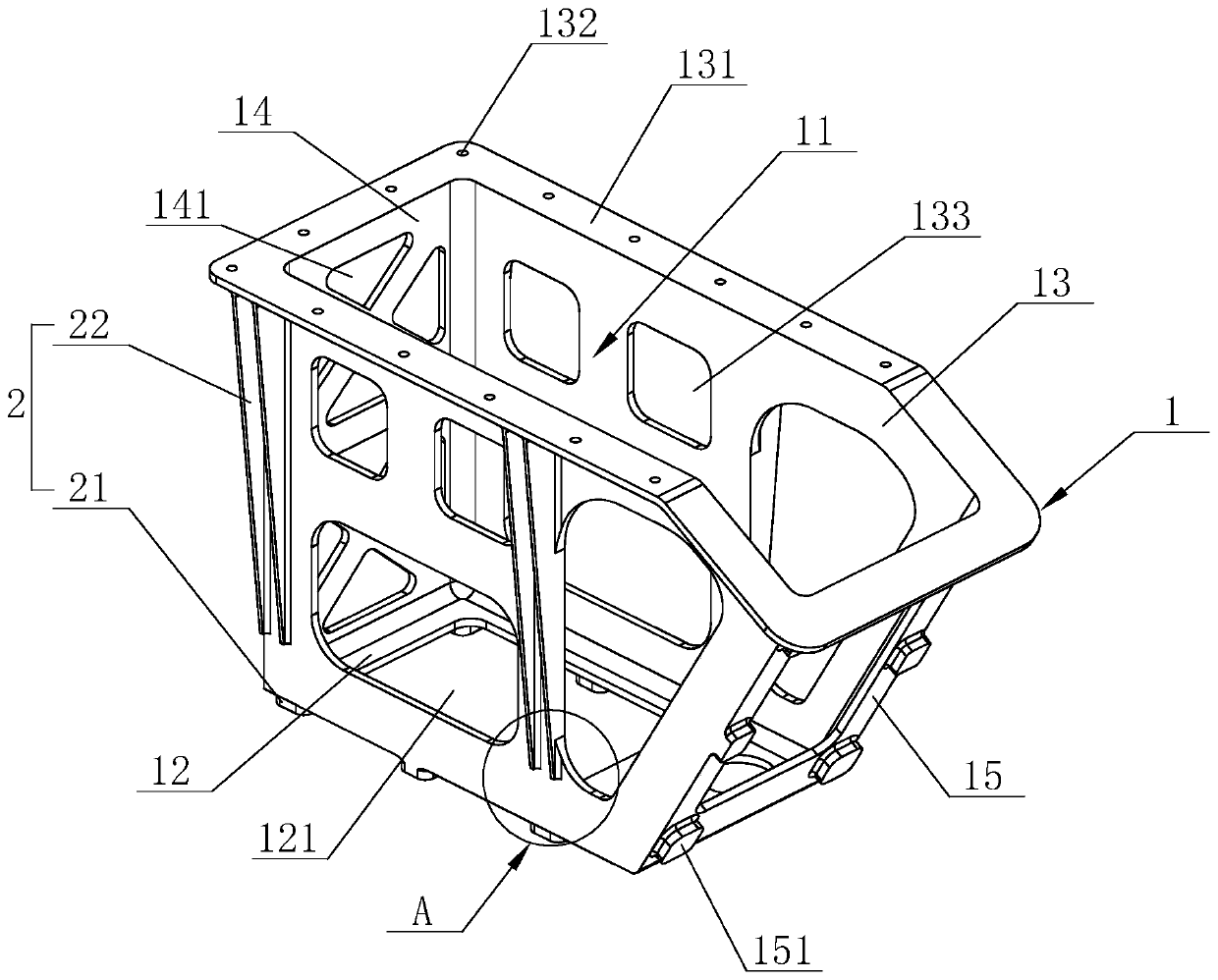

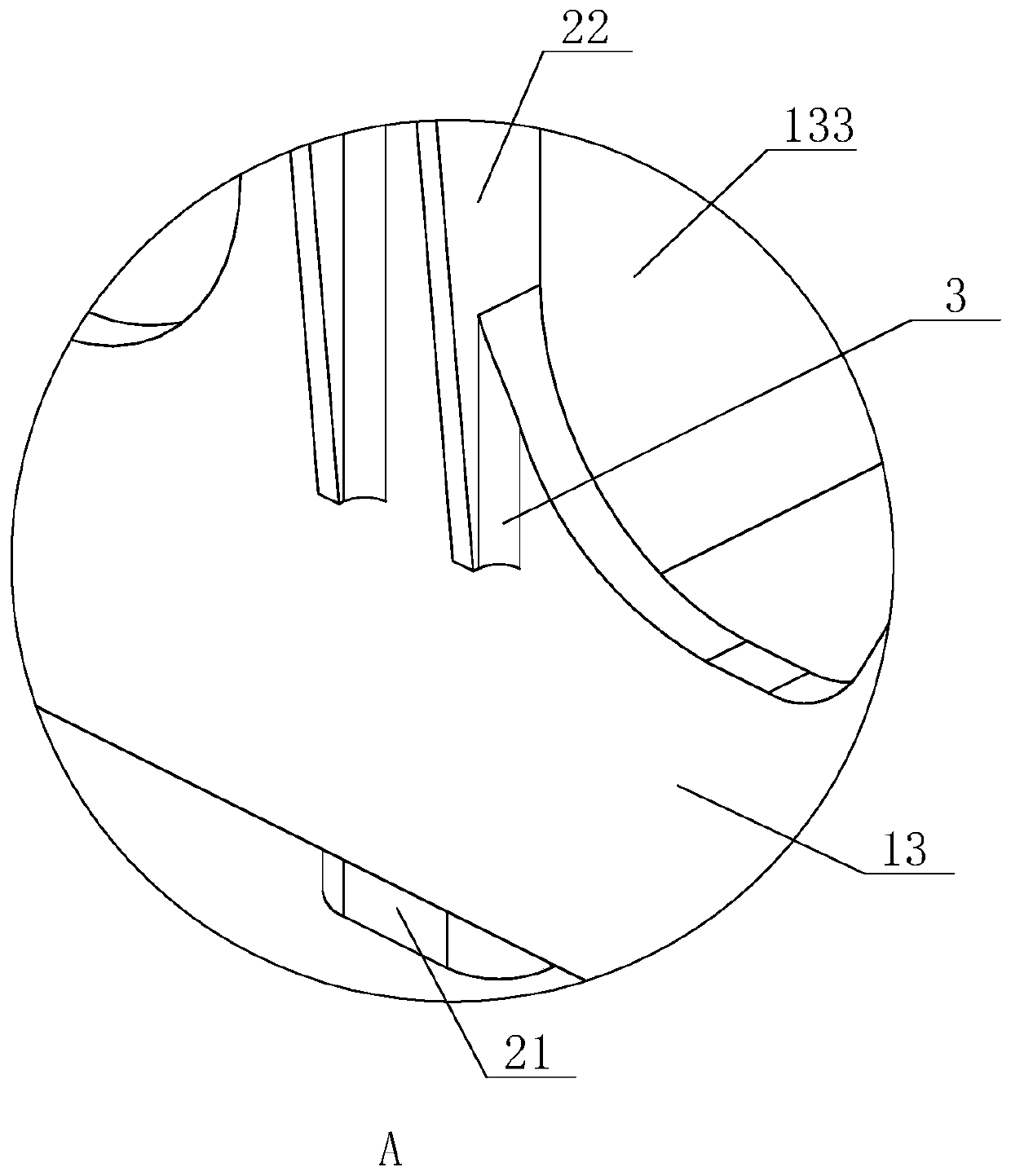

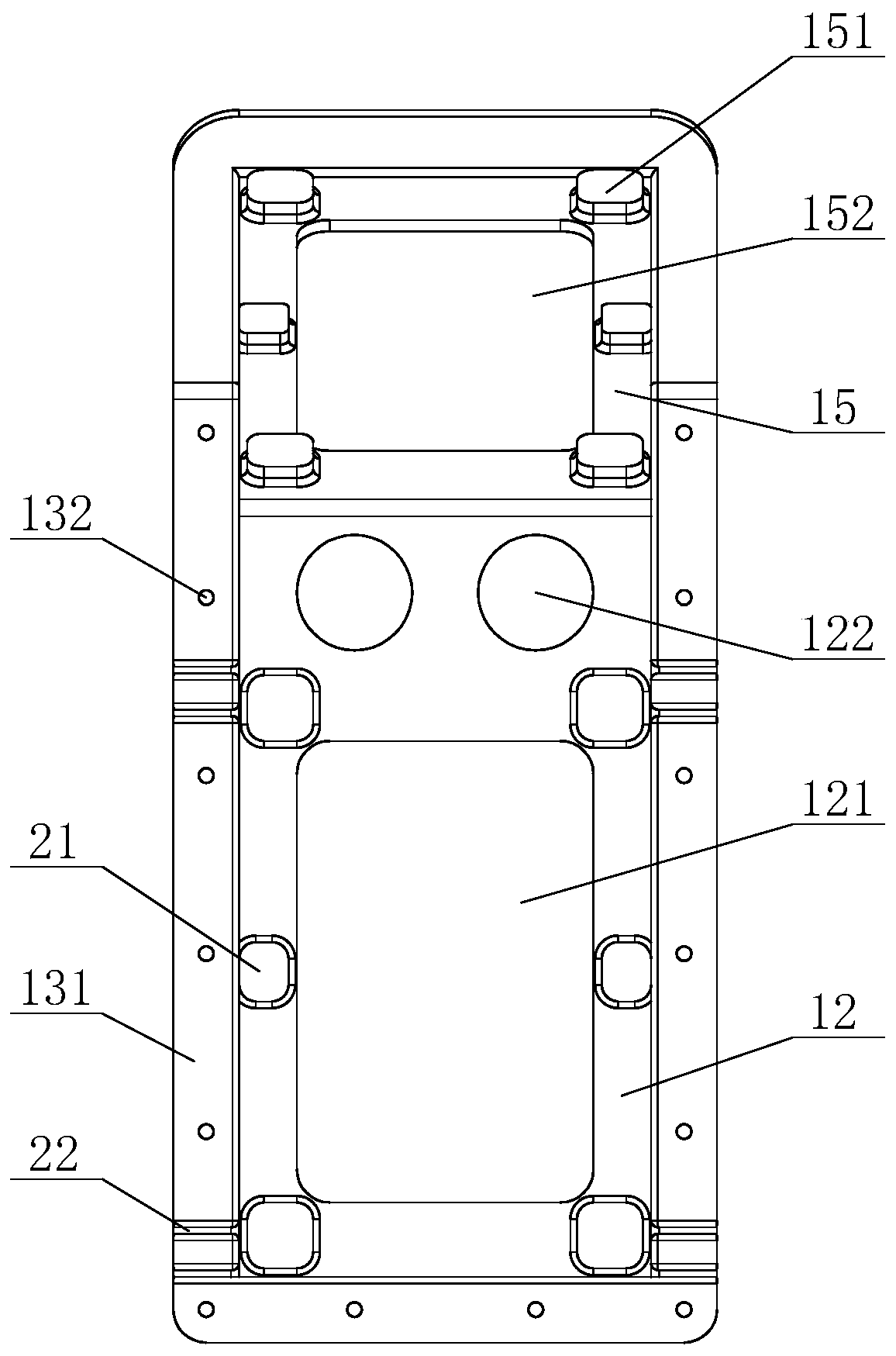

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] refer tofigure 1 , is a rocket engine bracket disclosed in the present invention, comprising a bracket body 1 hollowed out inside. The entire engine bracket is made of 2A14 aluminum alloy material, which is cut into a specific shape by a CNC machining center, so all connection methods in this embodiment are integrally formed and fixedly connected. 2A14 aluminum alloy is a kind of material belonging to hard aluminum alloy. The main chemical components are zinc, iron, magnesium, aluminum, etc. It has good machinability, good resistivity, spot welding and seam welding performance.

[0037] Among them, refer to figure 1 The rocket engine bracket also includes reinforcing components 2 symmetrically fixedly connected to the outside of the bracket body 1, and the bracket body 1 is provided with a square opening 11 for embedding the engine. The reinforcement...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap