Wound lithium-ion cell and preparation method thereof

A lithium-ion, wound-type technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of easy shrinkage of the diaphragm, fire and explosion, short circuit of positive and negative electrodes, etc., and achieve the effect of improving the thermal abuse safety certification test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

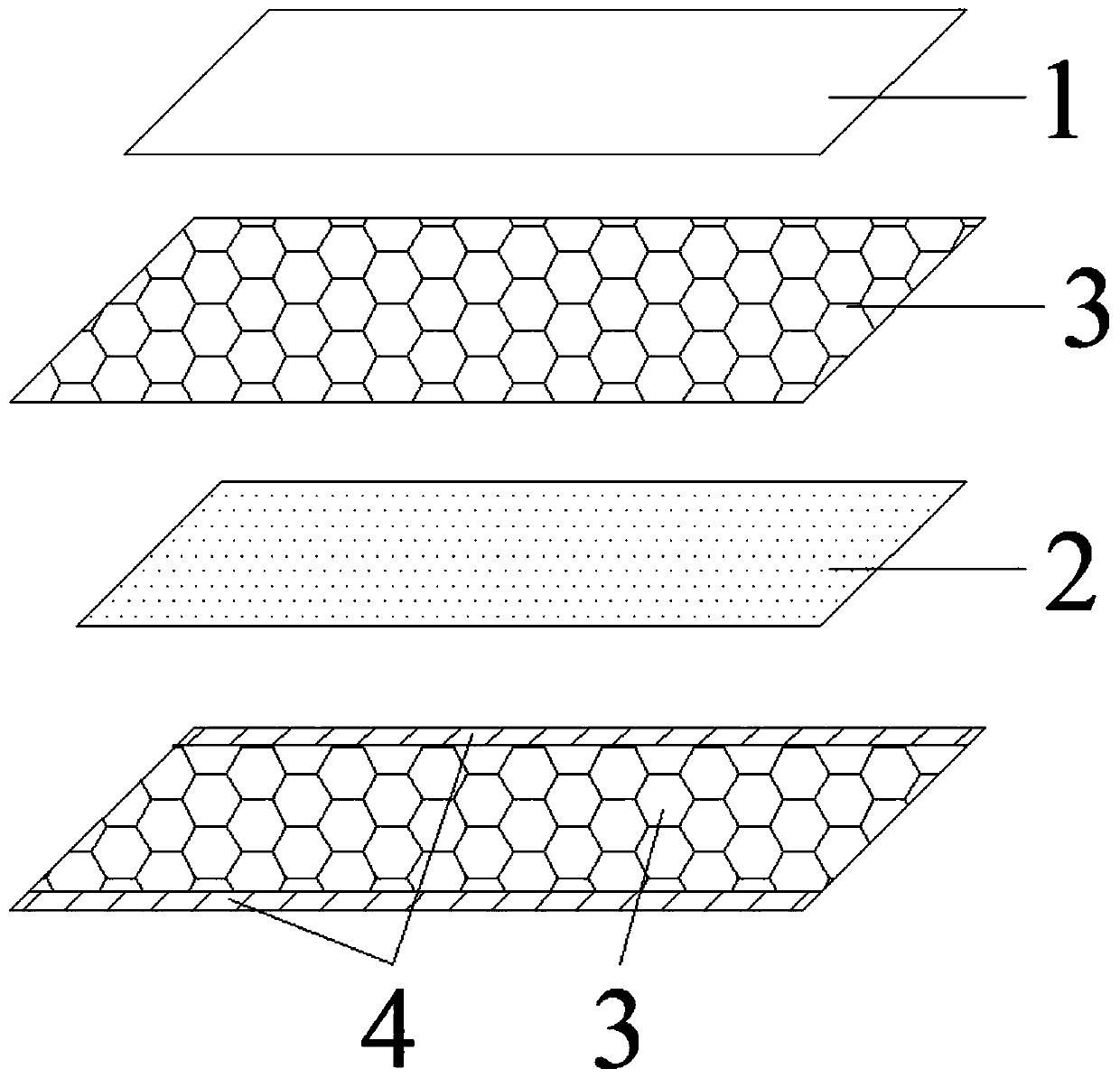

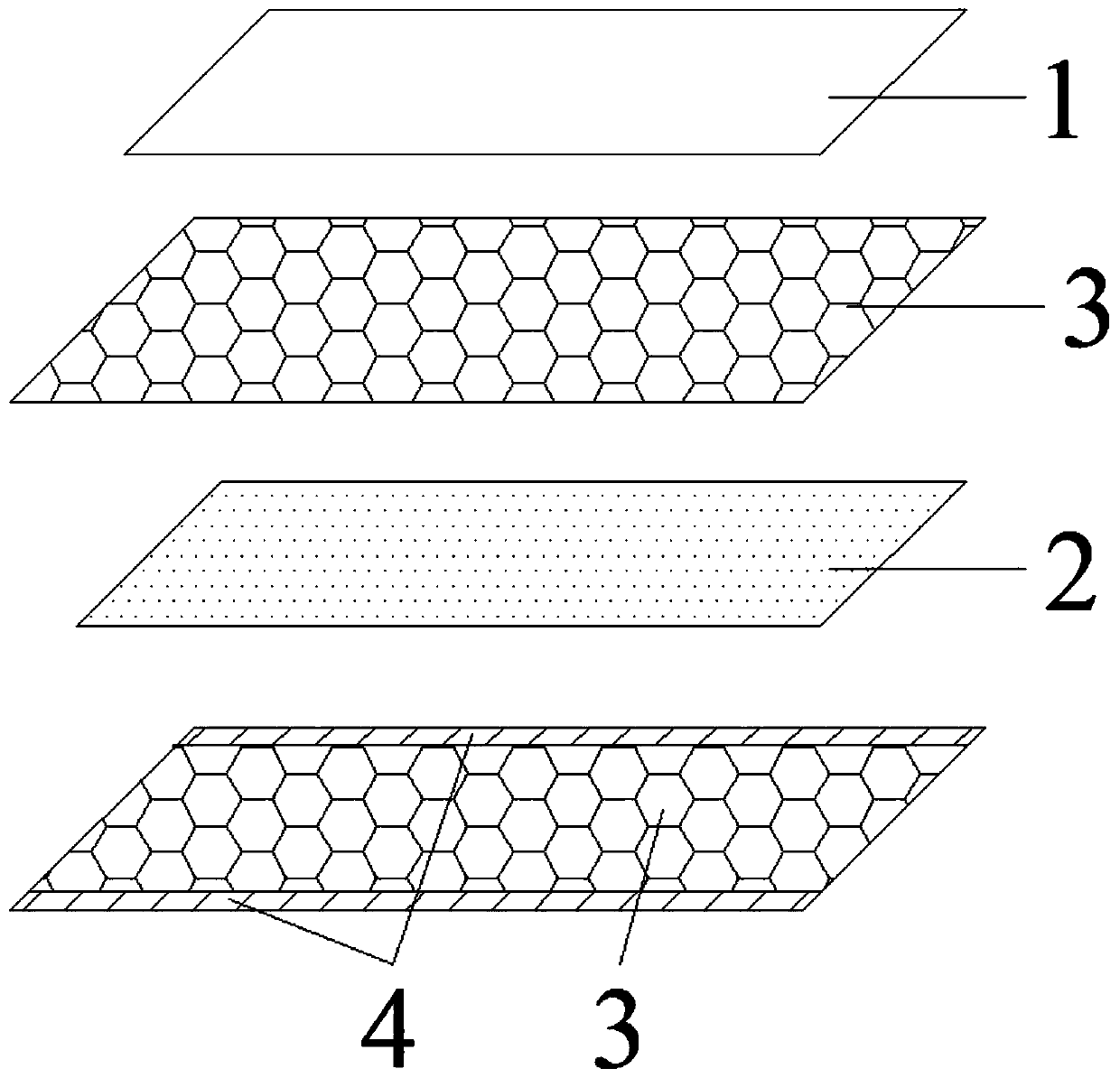

[0028] This embodiment provides a winding lithium ion battery, comprising a positive electrode sheet 1, a negative electrode sheet 2, and a separator 3 arranged between the positive electrode sheet 1 and the negative electrode sheet 2, and the side of the separator 3 facing the negative electrode sheet 2 is provided with a bonded Layer 4, the adhesive layer 4 is located on the upper edge and the lower edge of the separator 3, two adjacent separators 3 are bonded by the adhesive layer 4 and the negative electrode sheet 2 is wrapped inside.

[0029] Further, the length of the adhesive layer 4 is greater than the length of the negative electrode sheet 2 .

[0030] Further, the thickness of the adhesive layer 4 is 1 μm, and the width of the adhesive layer 4 is 1.5 mm.

[0031] Further, the melting point of the adhesive layer 4 is 80-120° C., and the melting point of the separator 3 is higher than the melting point of the adhesive layer 4 .

[0032] Further, the adhesive layer 4 d...

Embodiment 2

[0039] This embodiment provides a winding type lithium ion battery. The difference from Embodiment 1 is the bonding layer 4. The length of the bonding layer 4 is equal to the length of the negative electrode sheet 2. The bonding layer 4 is polypropylene glue. The layer 4 has a thickness of 0.6 μm and the adhesive layer 4 has a width of 1 mm.

[0040] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0042] This embodiment provides a winding lithium ion battery. The difference from Embodiment 1 is the bonding layer 4, which is polyacrylate glue, and the thickness of the bonding layer 4 is 3 μm. The width is 1mm.

[0043] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap