Universal accurate plate making method for clothes

A universal and clothing technology, applied in the direction of tools for sewing clothes, etc., to achieve a beautiful rhythm and improve the effect of wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

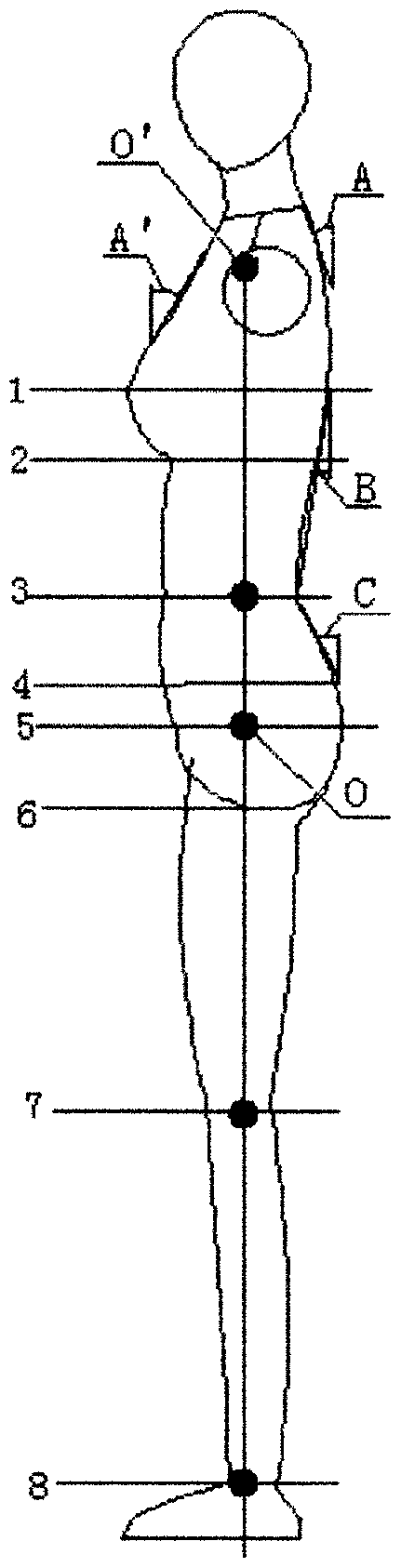

Method used

Image

Examples

Embodiment 1

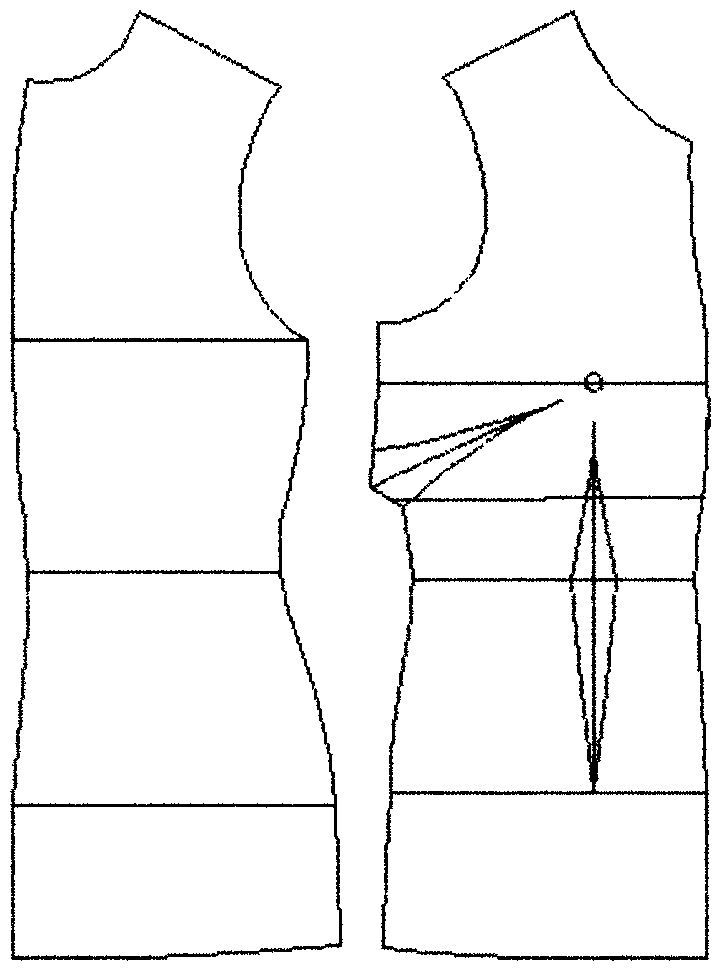

[0027] A fitted blouse such as figure 2 As shown, the plate-making parameters are obtained by measuring the body (the data is omitted here), and the plate-making steps are as follows:

[0028] 1) Draw bust, underbust, waist, abdomen and hip lines on the cardboard according to the distance of each circumference line;

[0029] 2) Draw the front (back) middle seam, and mark the structural points of each width, circumference, etc. on the cardboard;

[0030] 3) According to relevant data such as neckline and armhole, connect each structural point to form a contour line;

[0031] 4) According to the relevant height difference and girth difference, calculate the waist and body side saving, and draw it on the cardboard reasonably;

[0032] 5) The chest dart is determined by the inclination of the neck and chest; the dart of the back seam at the base of the neck is determined by the inclination of the nape; the dart and dart of the back waist is determined by the inclination of the ...

Embodiment 2

[0035] A well-fitting men's top, such as image 3 shown. The board-making parameters are obtained from body measurements. The model is obese (data omitted), and the board-making steps are the same as above.

Embodiment 3

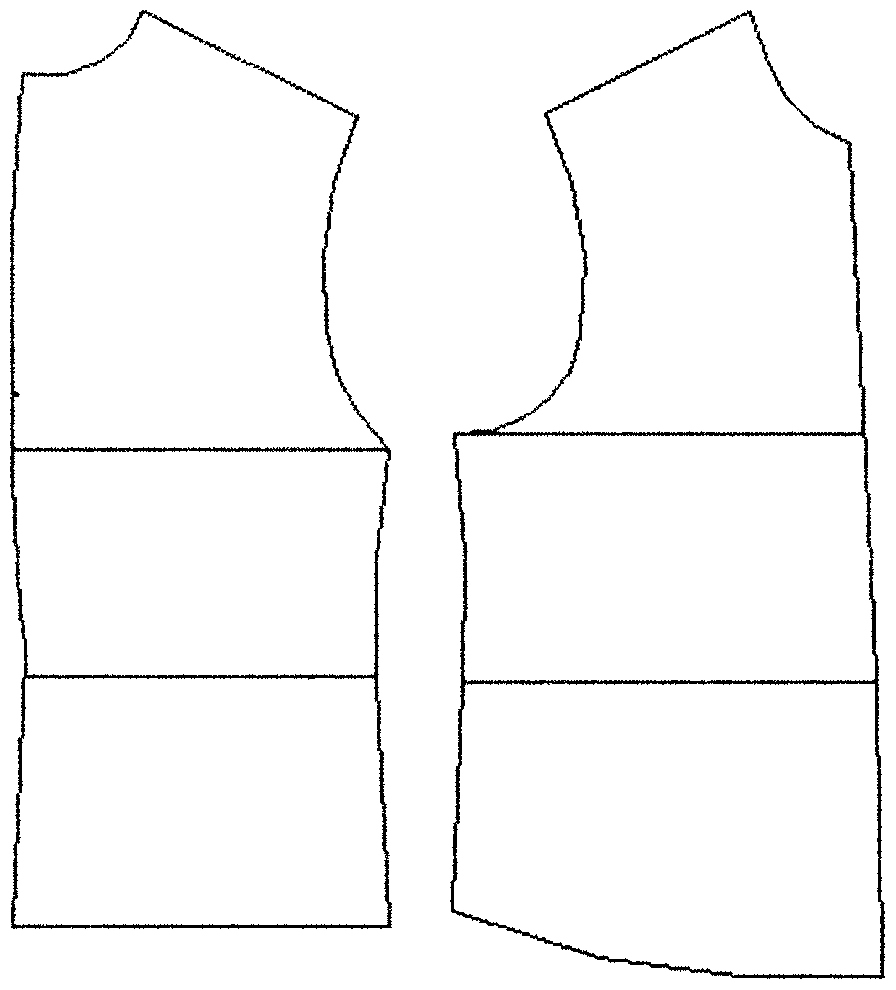

[0037] A pair of fitted women's pants, such as Figure 4 As shown, the plate-making parameters are obtained by measuring the body (the data is omitted here), and the plate-making steps are as follows:

[0038] 1) According to the distance of each circumference line, draw the waist circumference, abdomen circumference, hip circumference line, crotch line, knee line and ankle line on the cardboard;

[0039] 2) Draw the front and rear crotch lines according to the crotch data, and determine the shape of the back seam of the trousers according to the inclination angle of the waist and hips, determine the front and rear waist points, and the center line of the trouser legs, and mark the necessary structural points;

[0040] 3) connect each structure point to form the contour line of garment piece;

[0041] 4) According to the difference in girth, calculate the saving of the waist, and draw it on the cardboard reasonably;

[0042] 5) Connect each inflection point with an appropria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com