Flow distribution control method of high-rise building central flue system

A technology of flue system and control method, which is applied in the direction of heating method, oil fume removal, vertical pipeline, etc., can solve the problems of high energy consumption, insufficient energy saving, etc., achieve less loss, eliminate the difference in smoke exhaust effect, and control the process efficiently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

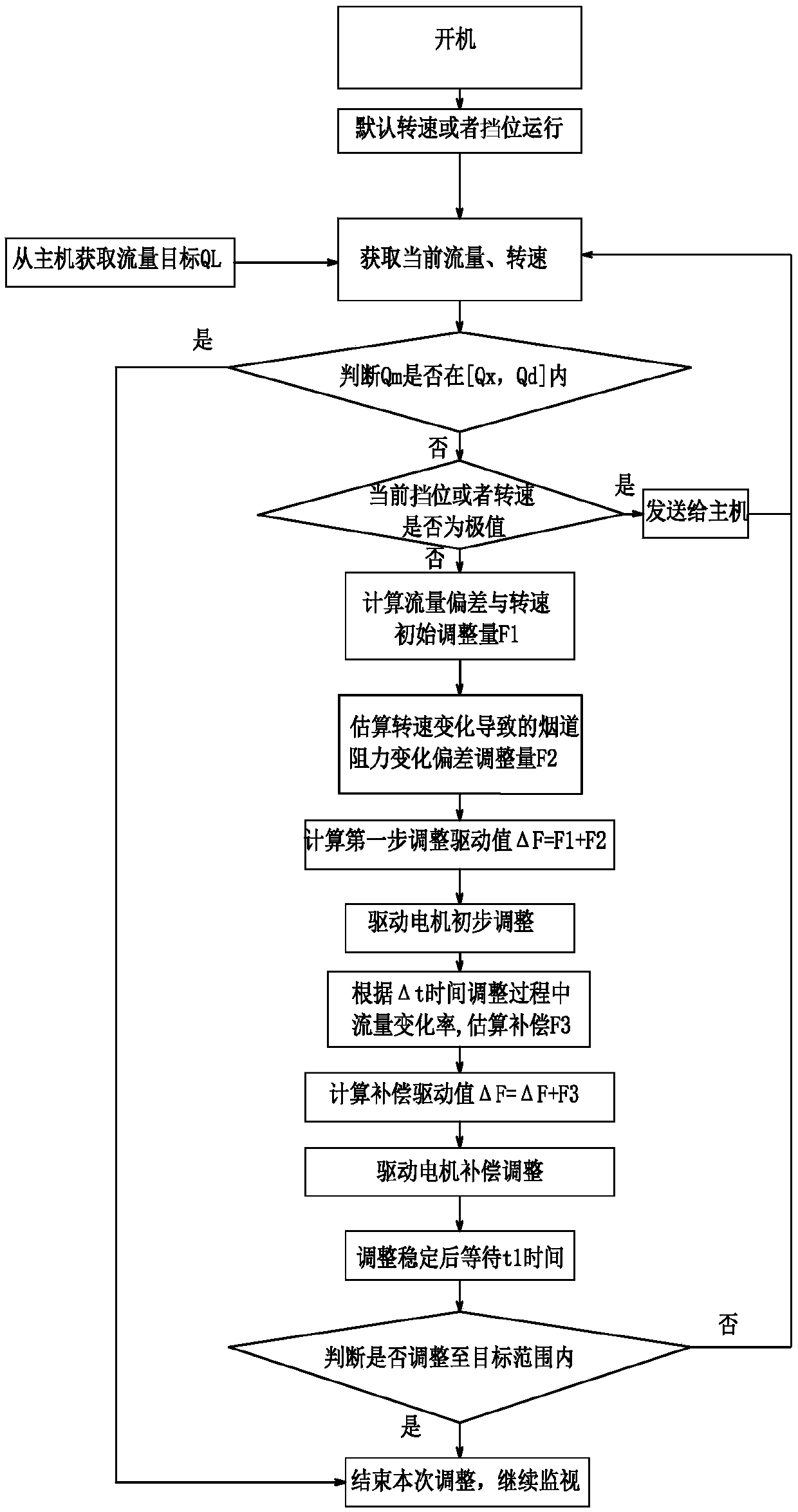

[0066] like Figure 1 to Figure 6 As shown, the central flue system of this embodiment includes indoor units 1 installed on different floors, and the air outlets of each indoor unit 1 are communicated with the common flue 3 through their own smoke pipes 2, and installed on the smoke pipes 2 There is a fan flow detection module 4, and the fan flow detection module 4 may use a flow speed detection module or a pressure detection module. The flow distribution control method of the central flue system of a high-rise building pre-sets the indoor unit target flow QL within the target range [Qx, Qd], and the flow distribution control method includes a slave control method and a master control method.

[0067] Wherein, the slave control method includes the following steps:

[0068] ①. Turn on any indoor unit and run at the default speed or gear;

[0069] ②. Detect and calculate the current flow Qm through the fan flow detection module; calculate the motor speed of the corresponding i...

Embodiment 2

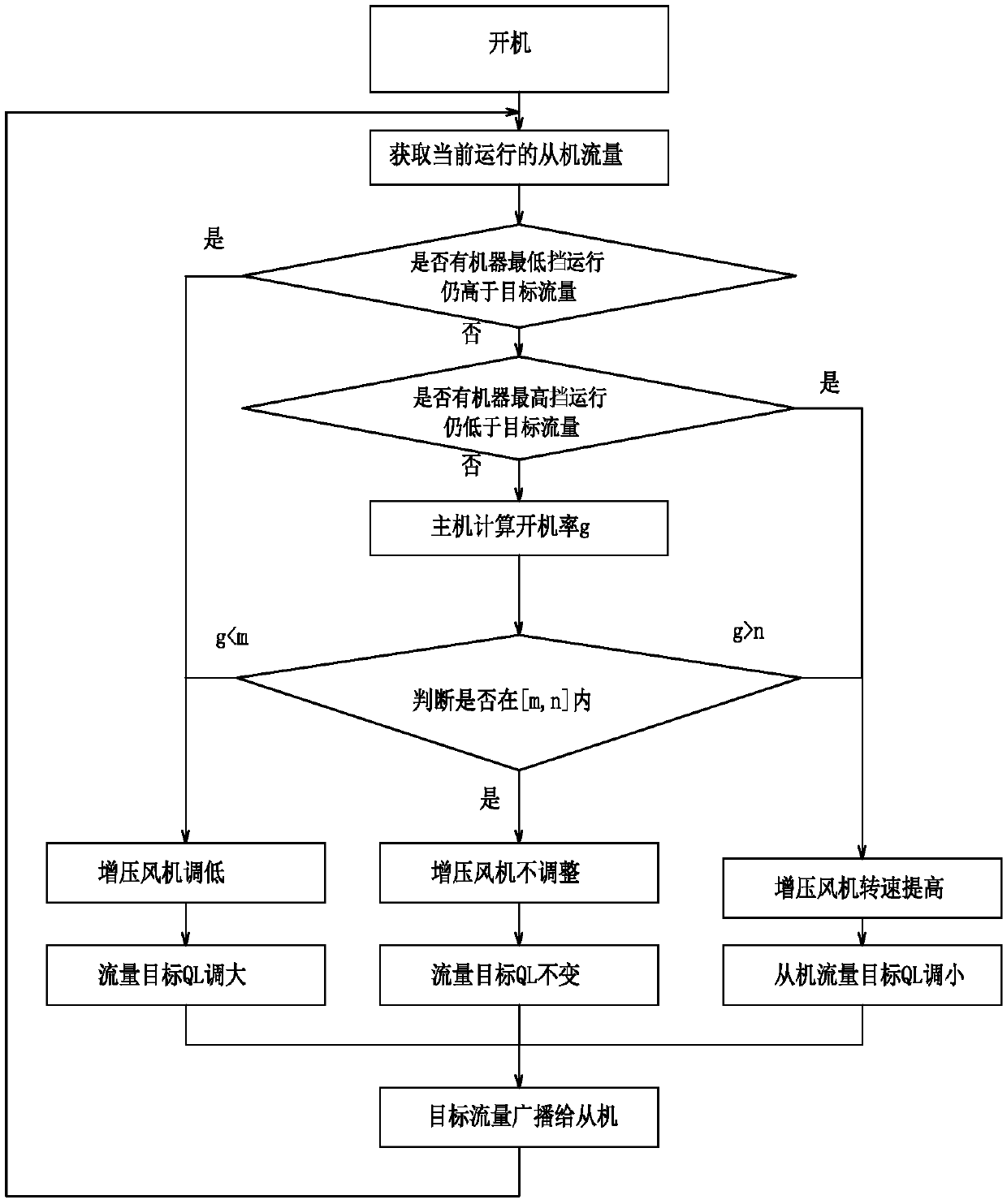

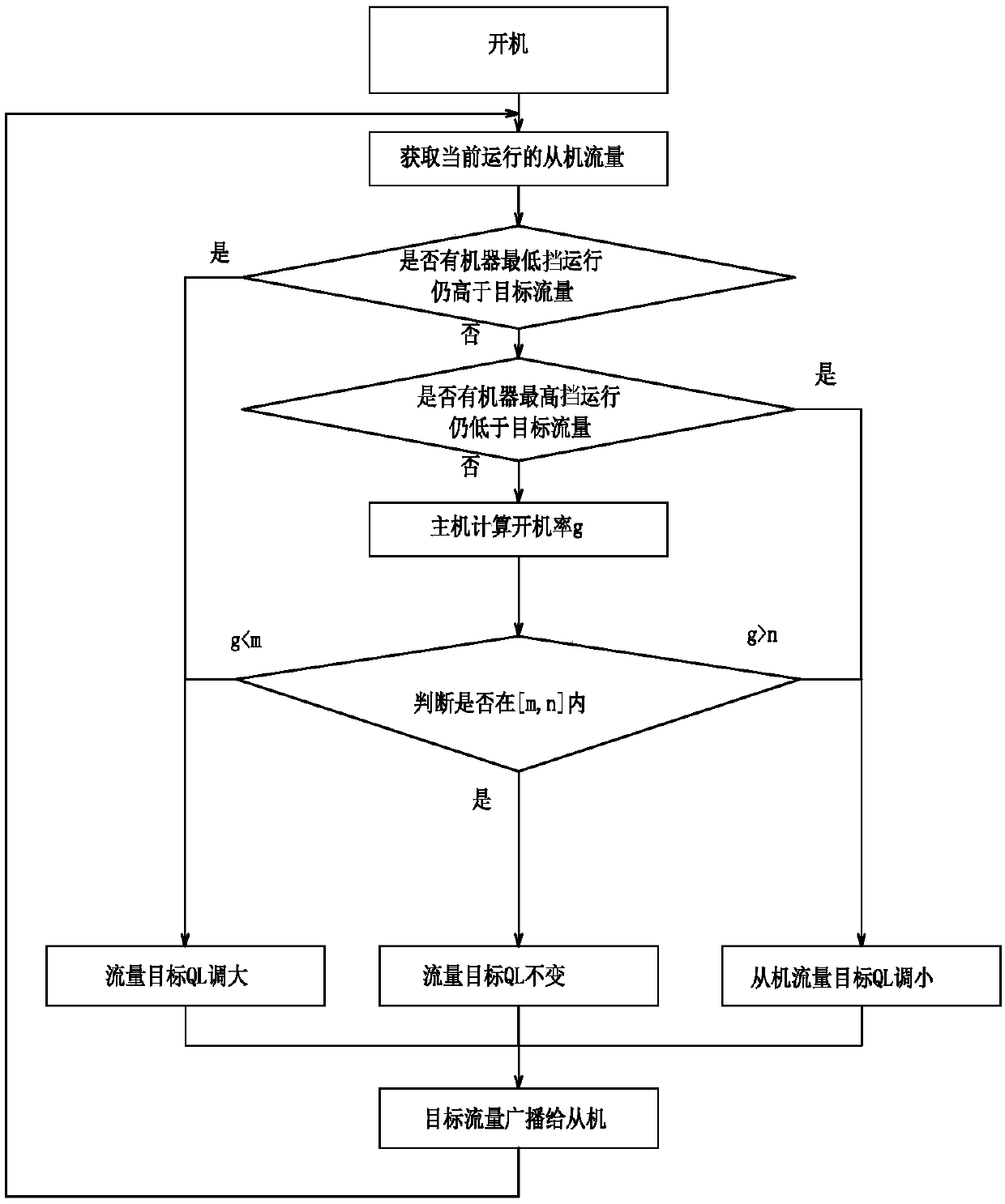

[0103] like Figure 7 and Figure 8 As shown, the host in this embodiment is one of the turned-on indoor units 1, and accordingly, the host control method includes the following steps:

[0104] ①, the main machine is turned on first and is in the stand-alone running state;

[0105] ②. Obtain other slave machine startup information and flow information;

[0106] ③. Determine whether the flow rate of the machine is still higher than the target flow rate when the machine is running at the lowest gear.

[0107] If so, increase the target flow QL of the slave machine;

[0108] If not, go to step ④;

[0109] ④. Determine whether the flow rate of the machine is still lower than the target flow rate when it is running in the highest gear;

[0110] If so, the flow rate of the machine is still lower than the target flow rate when the machine is running at the highest gear, and the target flow rate of the slave machine should be reduced;

[0111] If not, go to step ⑤;

[0112] ⑤. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com