Spherical material storage and output device with detachable base plate

A technology of output device and chassis, applied in the direction of motion accessories, etc., can solve the problems of unsmooth material output, inconvenient disassembly, etc., and achieve the effect of smooth ejection, convenient installation and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

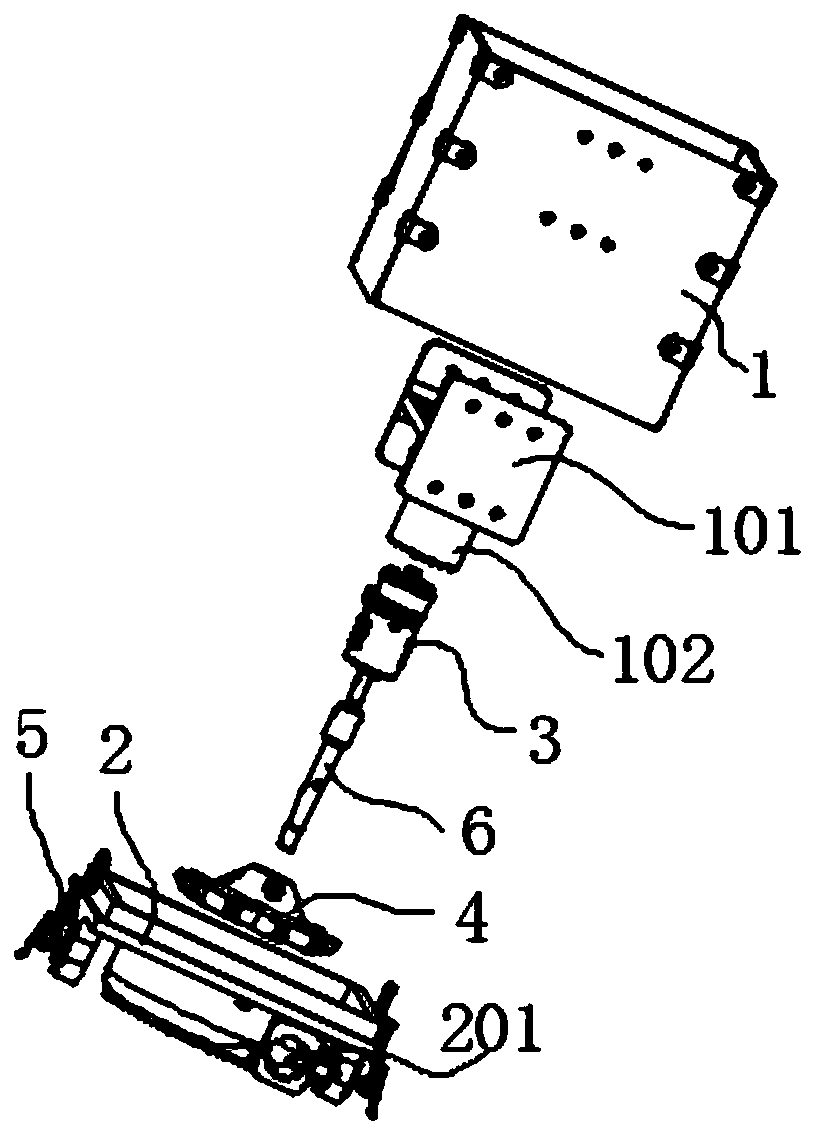

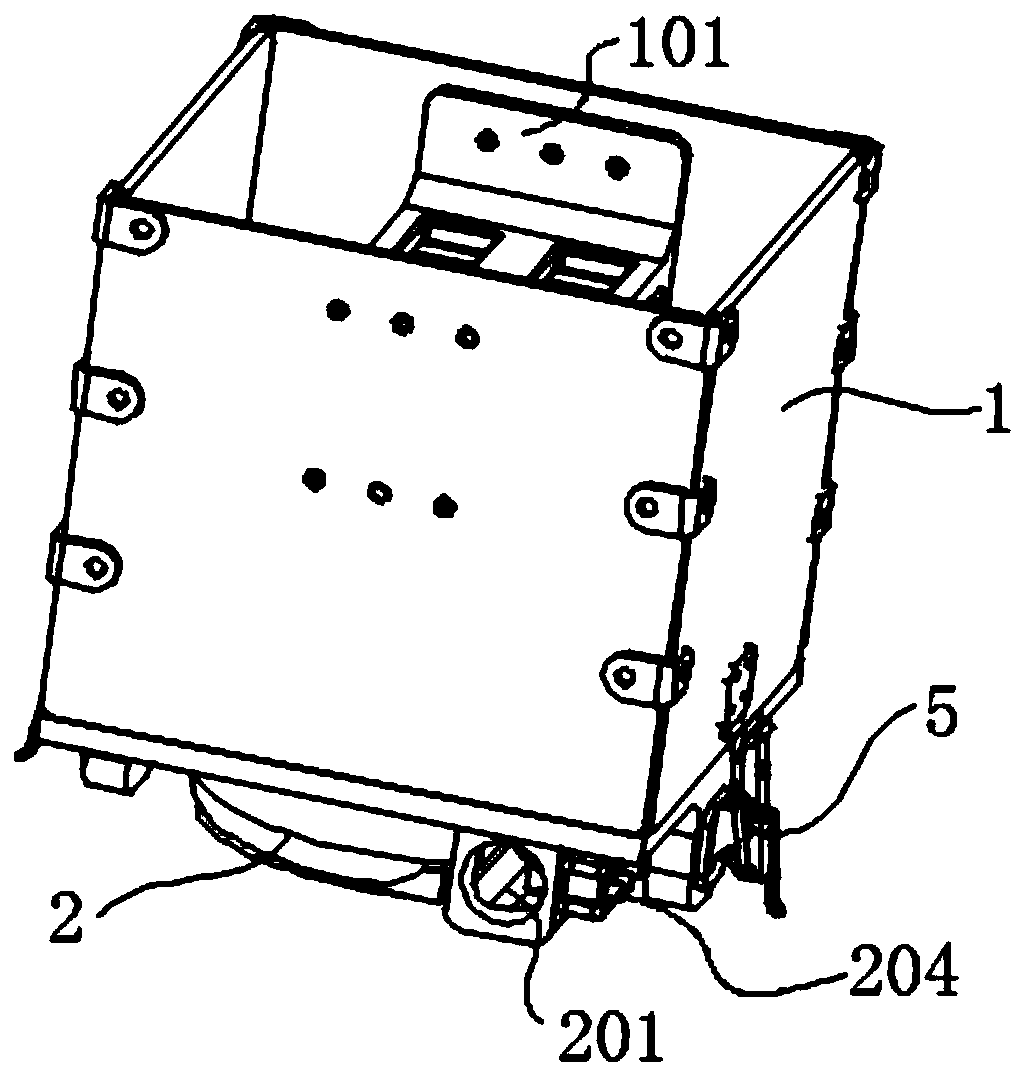

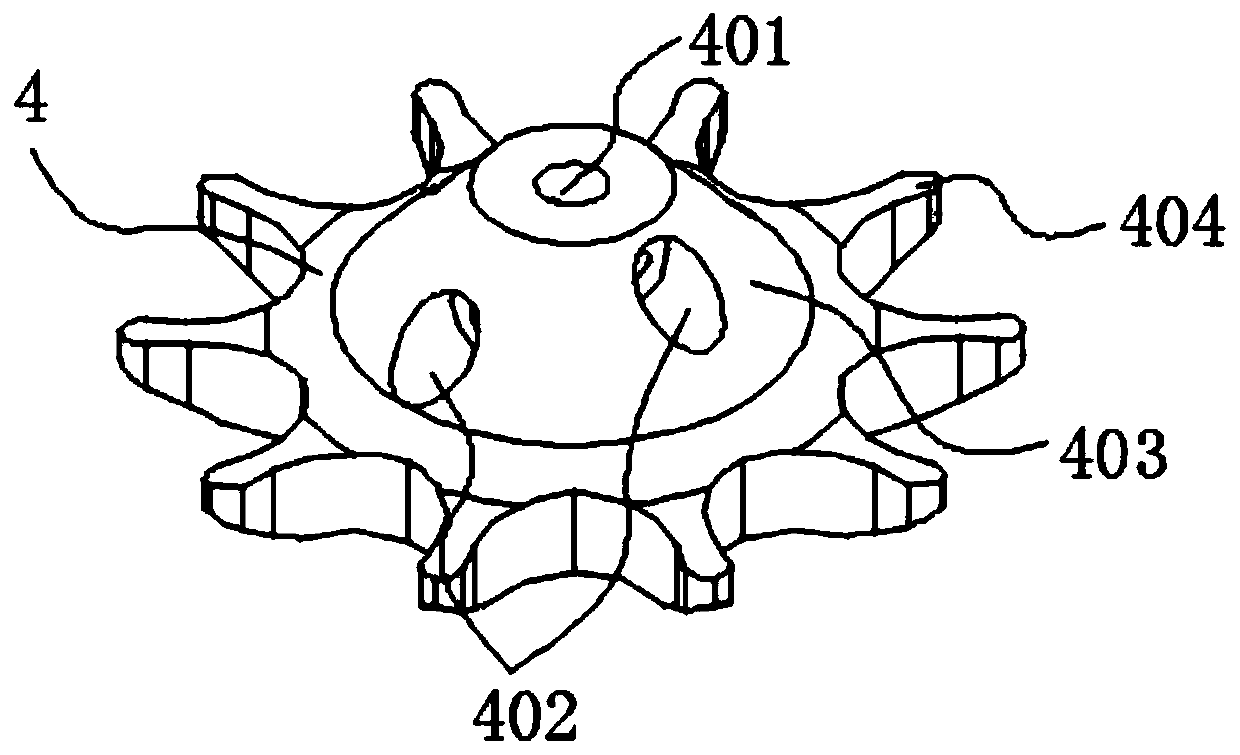

[0032] Such as Figure 1-7 Shown is an embodiment of a spherical material storage and output device with a detachable chassis, including a magazine 1 for placing materials, a chassis 2 provided with an ejection port 201, a motor 3, and a motor 3 that is connected to the motor 3 and extends into the chassis 2 Inside the dial 4, the chassis 2 is provided with a positioning groove, and the magazine 1 is provided with two opposite openings, and one of the openings faces the chassis 2 and cooperates with the positioning groove 202; the magazine 1 and the chassis 2 can be The connection is disassembled; the motor 3 is installed in the magazine 1 .

[0033]Specifically, the magazine 1 is detachably connected to the chassis 2 through a lock 5 . Fast installation and disassembly of the chassis 2 and the magazine 1 can be realized through the lock 5 , and the connection of the lock 5 is more durable.

[0034] Preferably, the magazine 1 is equipped with a cantilever beam 101 for instal...

Embodiment 2

[0045] Figure 8-10 Shown is another embodiment of a small-sized spherical material storage and output device of a new detachable chassis 2, the difference from Embodiment 1 is that specifically, the side wall of the ballistic path 203 is arc-shaped, and the radius of the arc is In order to eject the radius of the material, if there are too many spherical materials (output objects) piled up on the top of the chassis 2, the spherical materials leaning against the side wall can be squeezed by the dial wheel 4 and pushed upward along the spherical side wall, which is equivalent to pushing up the spherical side wall of the chassis 2. The material in the center is turned over, and since there is a larger movement space compared with the columnar side wall when the arc surface is pushed upward, the risk of material being stuck between the side wall and the picking wheel 4 is effectively reduced. At the same time, due to the effect of the arc surface, the gravity of the upper materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com