A channel test bench with adjustable structure size and liquid level height of open channel

A technology of structure size and liquid level height, applied in the field of channel test bench, can solve the problems of inability to achieve experimental measurement, fixed size, large structure size of channel test bench, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

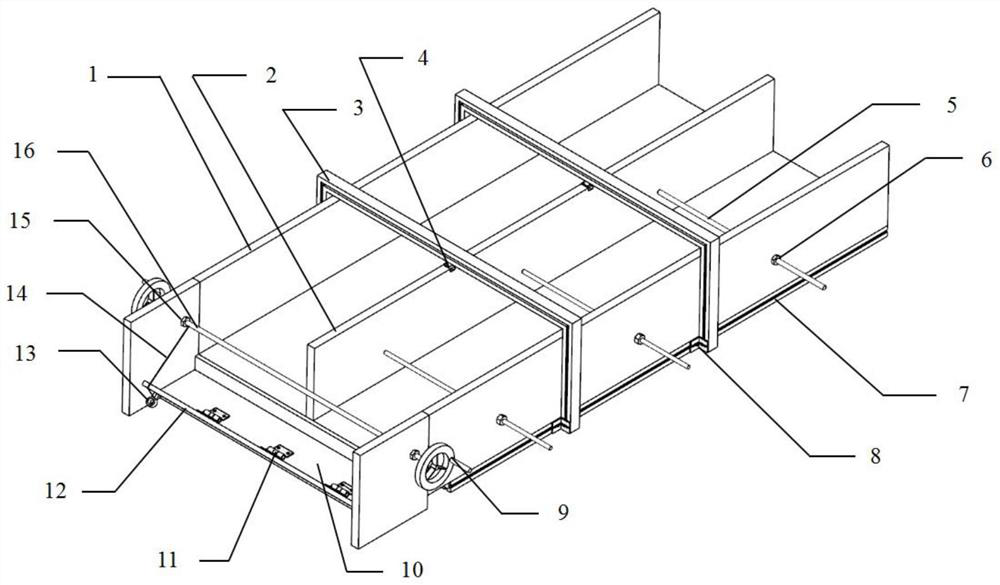

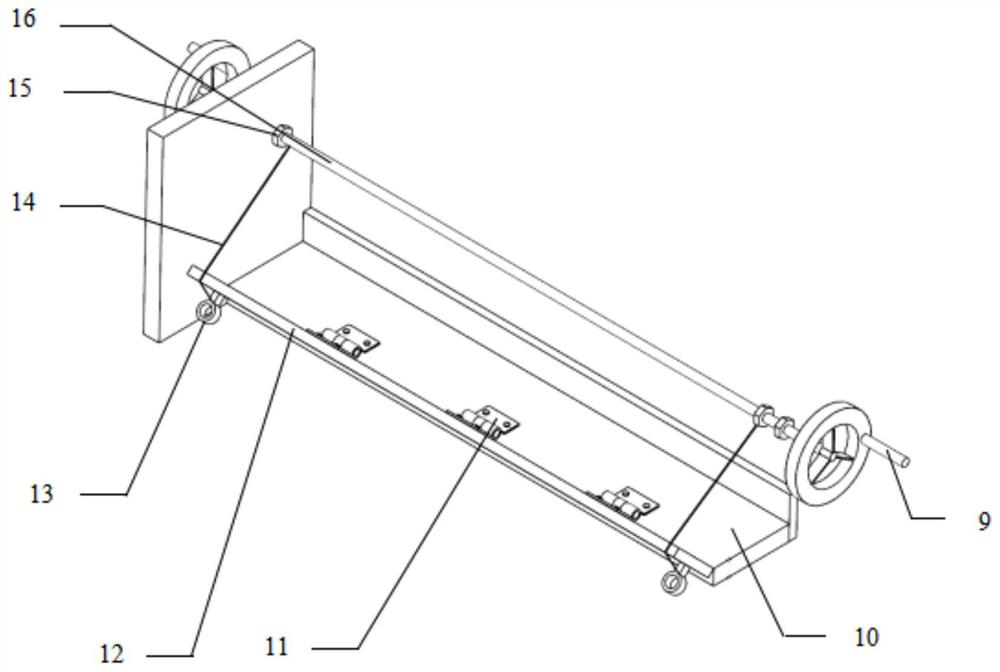

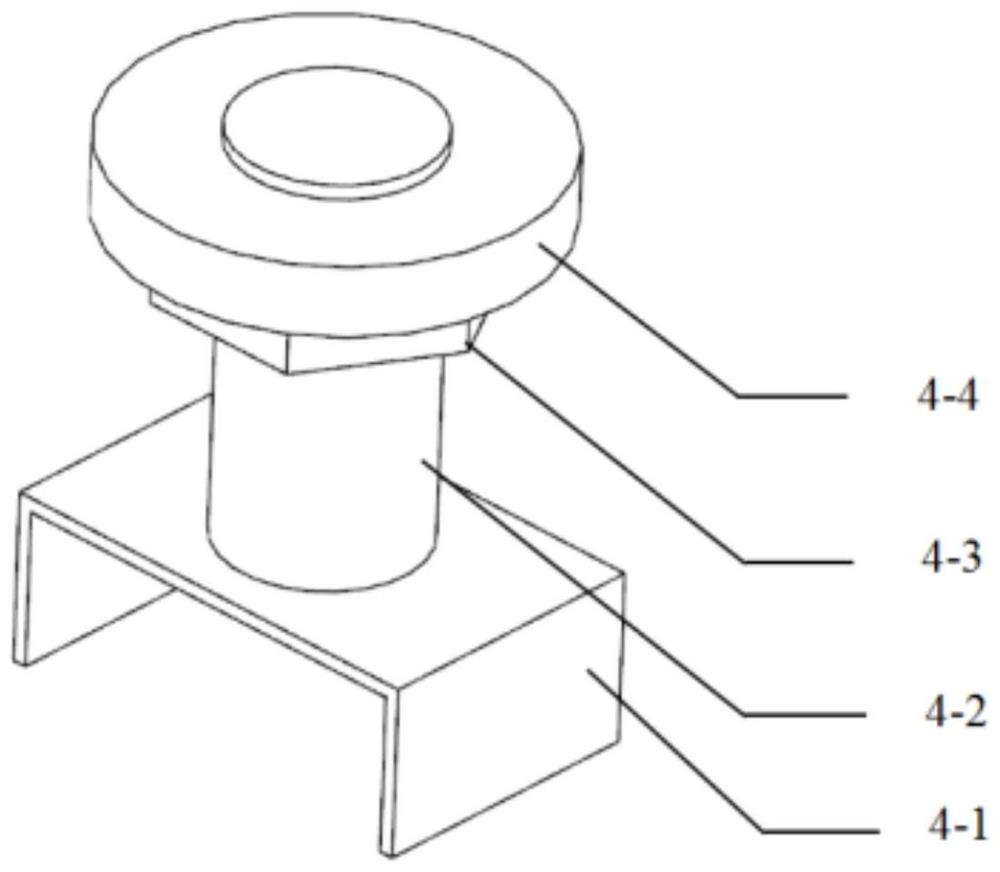

[0023] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a channel test bench with adjustable structure size and liquid level height of an open channel in this embodiment includes a channel 1, the channel 1 is a long strip channel, it also includes a movable plate 2, an aluminum profile Pressure frame 3, locking structure 4, multiple screw rods 5, multiple fixing nuts 6, two aluminum profile brackets 7, multiple aluminum angle structures 8 and sinking components, multiple screw rods 5 pass along the width direction of channel 1 Passing through a side plate of the channel 1, each screw rod 5 is connected and positioned by two fixing nuts 6, the movable plate 2 is movably installed in the channel 1 along the width direction of the channel 1, and the side end surface of the movable plate 2 Connected with a plurality of screw rods 5, two aluminum profile brackets 7 are respectively installed on the lower part of the two side plates in the le...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 1 to Figure 2 To describe this embodiment, the movable plate 2 of this embodiment is a strip plate, and the height of the movable plate 2 is flush with the upper end surface of the channel 1 . Such setting is convenient to meet the liquid level height requirement during the test and prevents water from splashing out. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 1 to Figure 2 The present embodiment will be described. The aluminum profile press frame 3 of the present embodiment is a groove-shaped press frame. Such setting is convenient for installation on the channel 1 without affecting the water flow experiment, and it is also convenient for observing the water flow. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com