Waterproof box overflow structure of drum washing machine and drum washing machine

A drum washing machine and waterproof box technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve problems such as water overflow, overflow to the outside, and foam accumulation that cannot be discharged, so as to improve the defoaming effect, avoid water overflow, prevent The effect of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

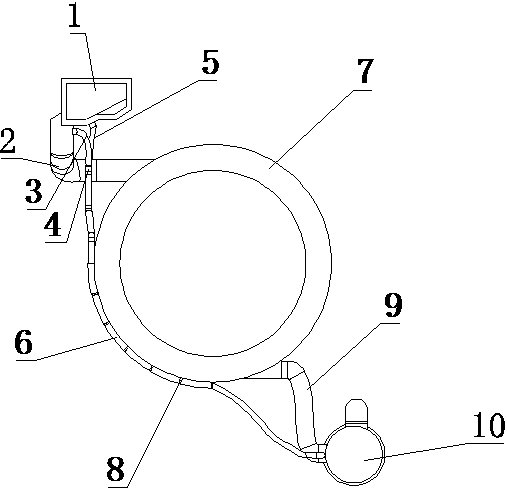

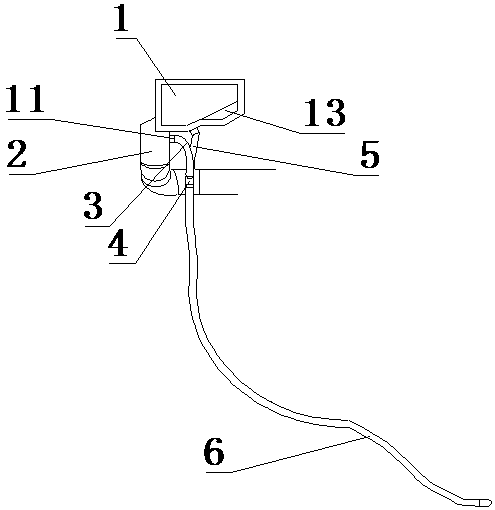

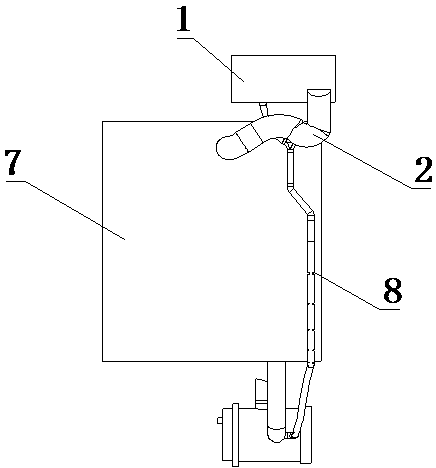

[0034] see Figure 1-Figure 5 , the present invention is a waterproof box overflow structure of a drum washing machine, comprising a first hose 3, a second hose 5, a third hose 6 and a three-way pipe 4, the three-way pipe 4 has three flow ports, One end of the first hose 3 communicates with the first flow port of the tee pipe 4, and the other end communicates with the upper part of the water inlet elbow 2; one end of the second hose 5 communicates with the second outlet of the tee pipe 4 The circulation port communicates with the bottom of the washing box 1 at the other end; one end of the third hose 6 communicates with the third communication port of the tee pipe 4 , and the other end communicates with the drain pipe 10 .

[0035] see Figure 1-Figure 5 , the back of the washing box 1 is provided with a water inlet, and the water inlet is connected to the water inlet solenoid valve through a hose; one side of the bottom of the washing box 1 is a straight part, and the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com