Establishment method of floating and slab staggering refined model of segment ring separated from shield tail

A construction method and shield tail segment technology, applied in earthwork drilling, design optimization/simulation, instrumentation, etc., can solve the problem of unclear change law of buoyancy time and unclear contribution of segment annulus joint shear stiffness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

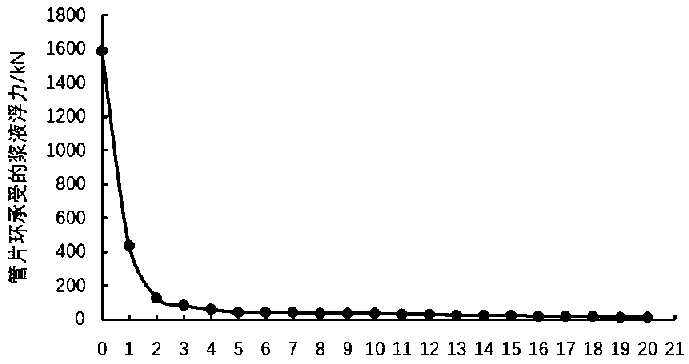

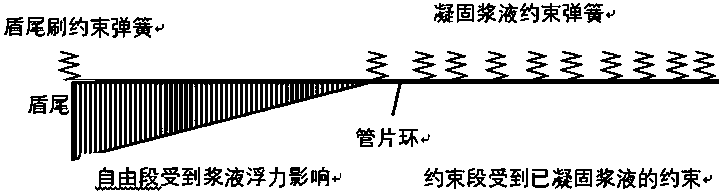

[0046]During the construction of a large-diameter shield for a Chengdu subway, the segment ring that has just come out of the shield tail has the risk of floating, misalignment or even leakage.

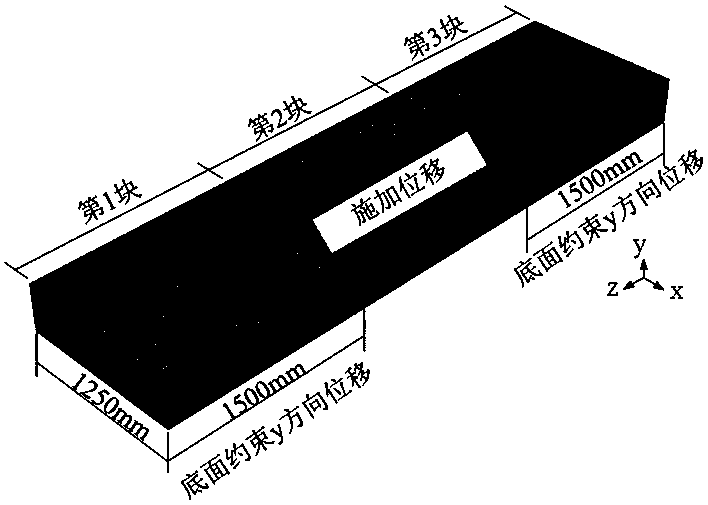

[0047] The first step is to investigate the structure and mechanical parameters of the shield segment ring

[0048] After investigation, the outer diameter of the tunnel is 8.3m, the inner diameter is 7.5m, and the ring width is 1.5m. The whole ring is composed of 7 segments (1+2+4), which are assembled with staggered seams. The segment is made of C50 concrete, the main reinforcement is HRB400 steel bar, the ring joint is connected by 19 M30 bolts, the mechanical performance of the bolt is 8.8, the initial gap between the bolt and the bolt hole is 3mm, and 19 independent positioning tenons are set, which are evenly distributed in the segment ring On the side, there is a 2.5mm free deformation space between the positioning tenon and the slot.

[0049] The second step is to determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com