Multi-connection electric push rod structure

An electric push rod and push rod technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of error, high cost, and connection damage in the synchronization effect, and achieve a large range of deceleration ratio and reduce installation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

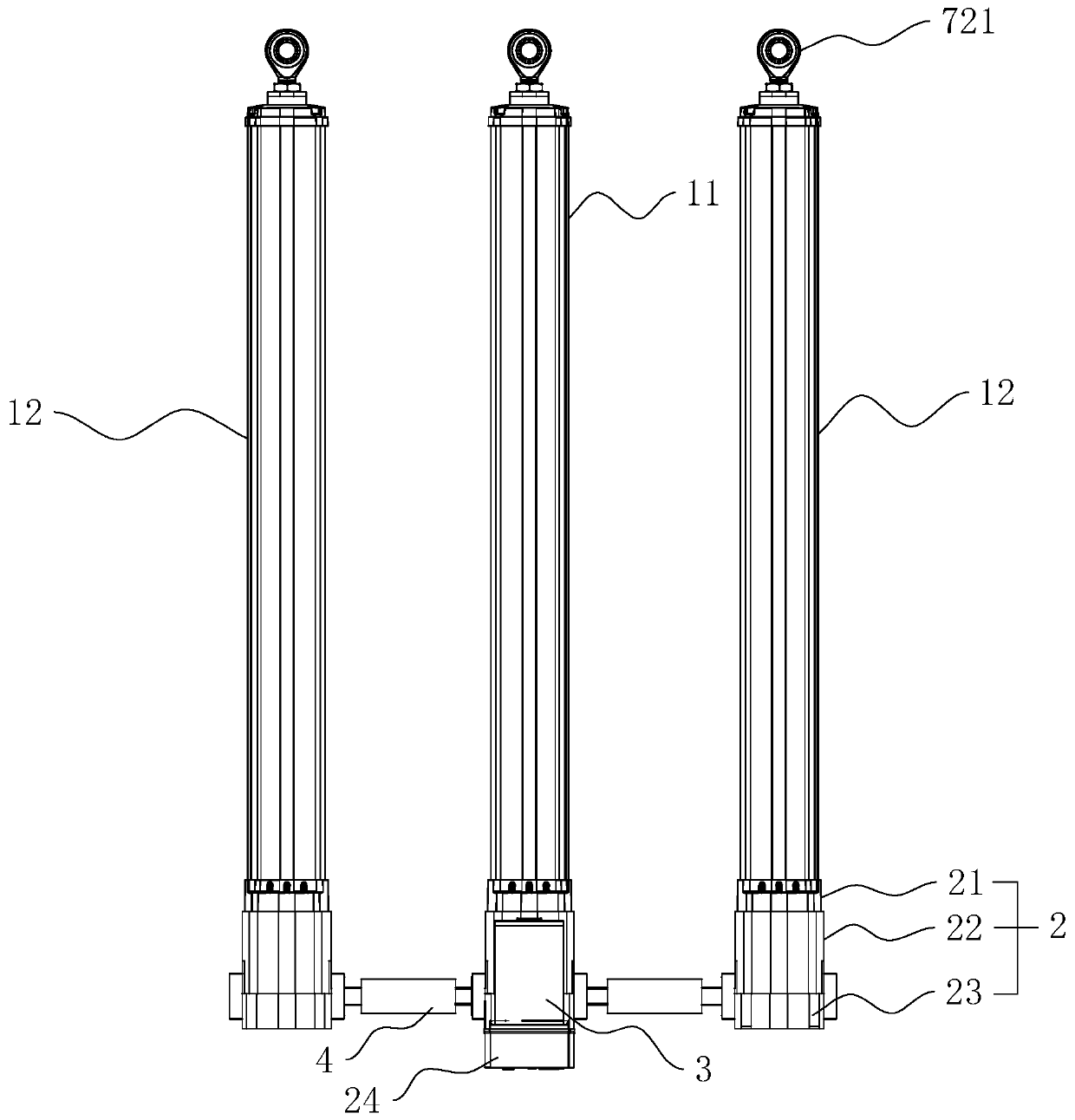

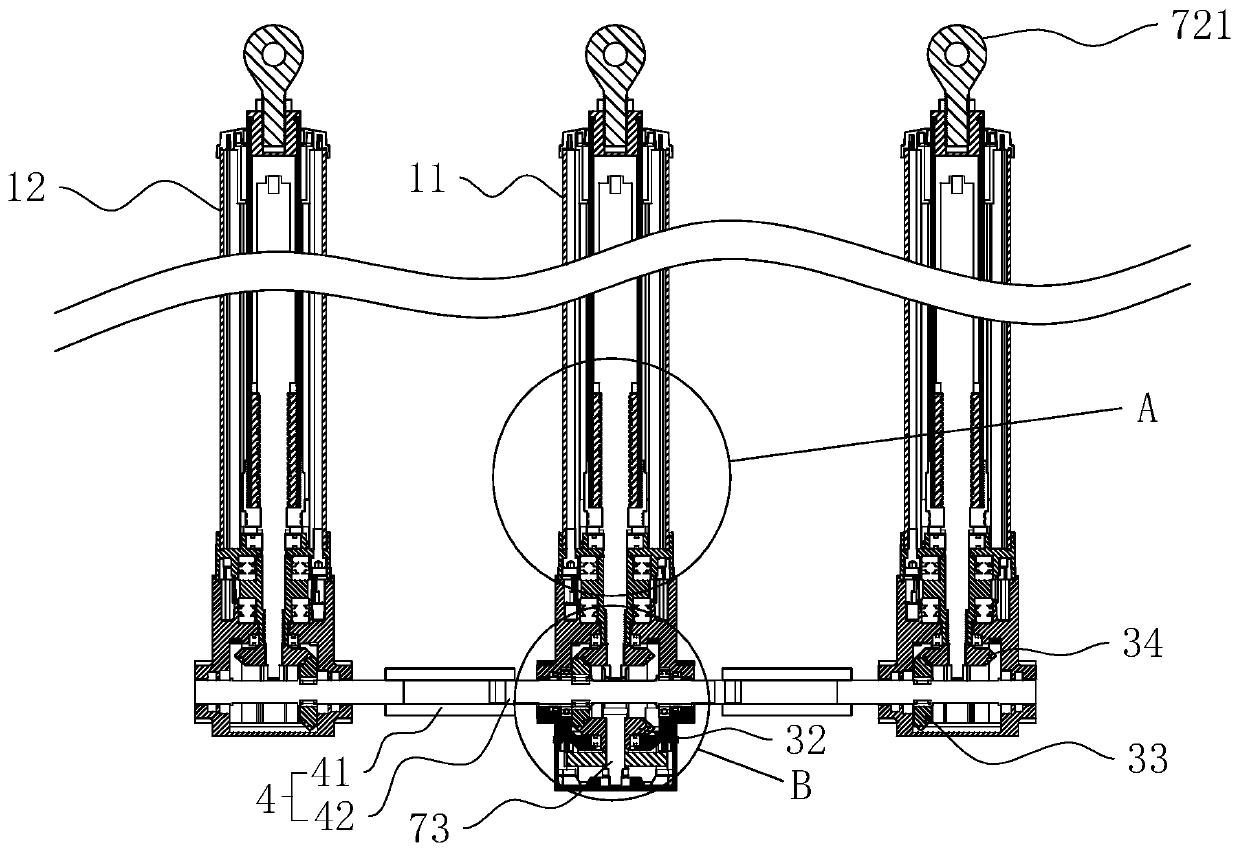

[0037]refer to figure 1 , is a multi-connected electric push rod structure disclosed in the present invention, including a driving push rod unit 11, two driven push rod units 12 respectively located on both sides of the driving push rod unit 11, a driving member 3 and a connecting active push rod unit 11 and the driven push rod unit 12 make the two synchronously retractable linkage 4.

[0038] like figure 1 and figure 2 As shown, the driving member 3 includes a driving motor 31 , a reduction gear set, a first bevel gear 32 , a second bevel gear 33 and a third bevel gear 34 .

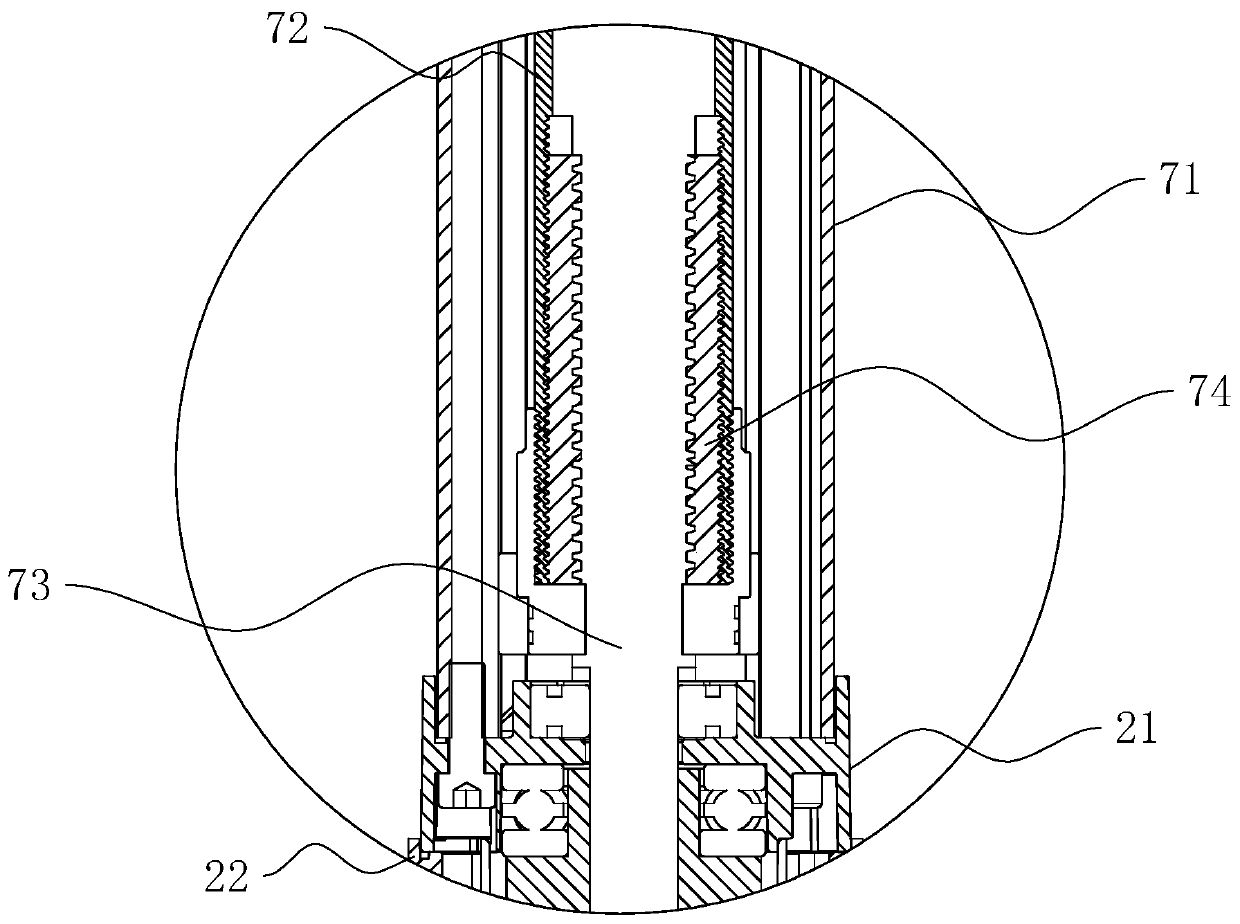

[0039] like figure 1 and image 3 As shown, both the driving push rod unit 11 and the driven push rod unit 12 include a base 2 , an outer tube 71 , an inner tube 72 , a screw rod 73 and a nut 74 .

[0040] like figure 1 and Figure 4 As shown, the base 2 includes a special-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com