Super high-rise building inhaul cable type flexible steel platform formwork and lifting method

A construction cable-type, steel platform technology, used in buildings, building structures, formwork/formwork/work frames, etc., can solve the problem of reduced climbing speed and climbing efficiency, difficult to effectively evaluate safety, and difficult to withstand use loads, etc. problems, to achieve the effect of eliminating height restrictions, achieving multi-floor continuous climbing, and increasing the height of a single climb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

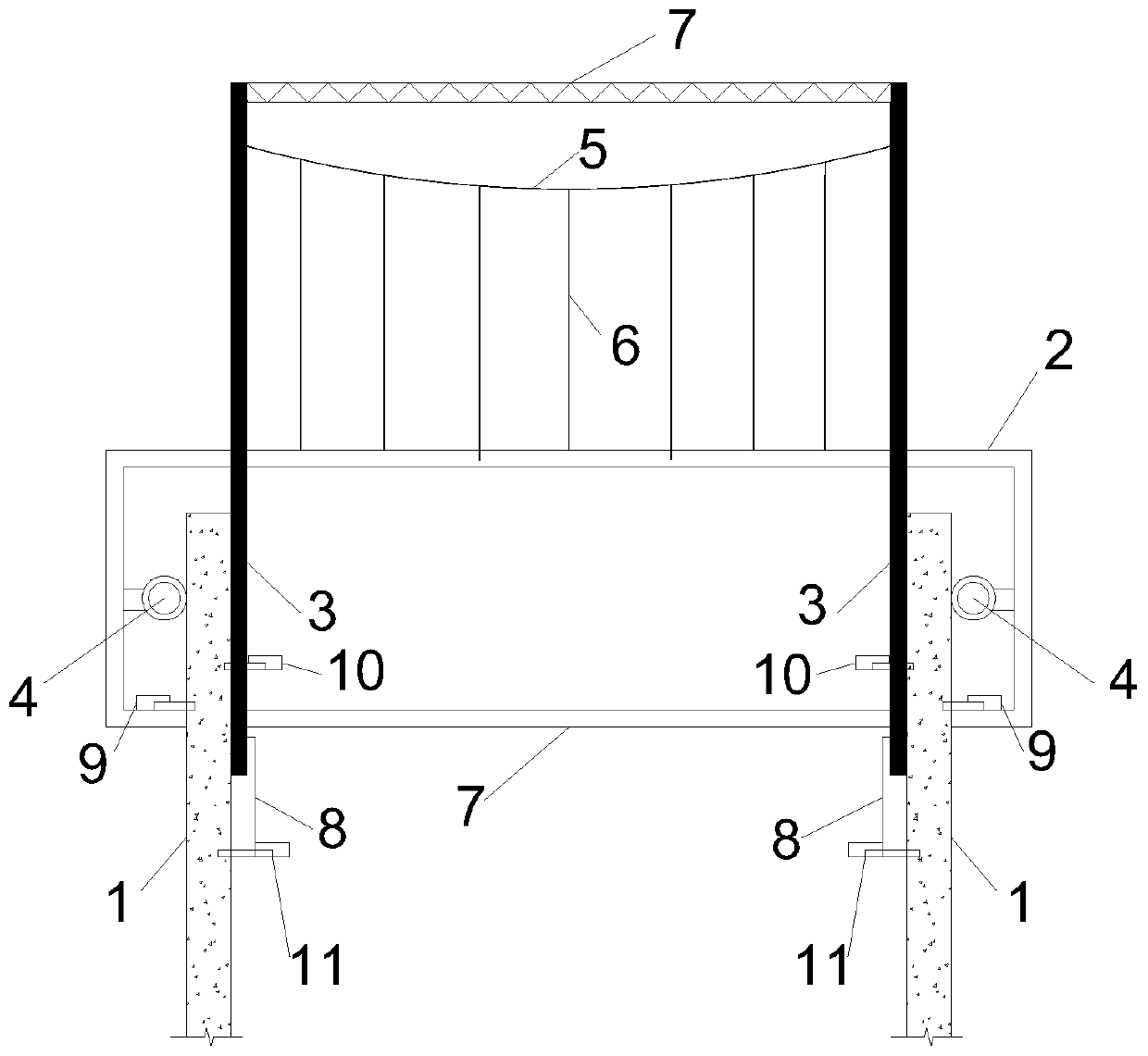

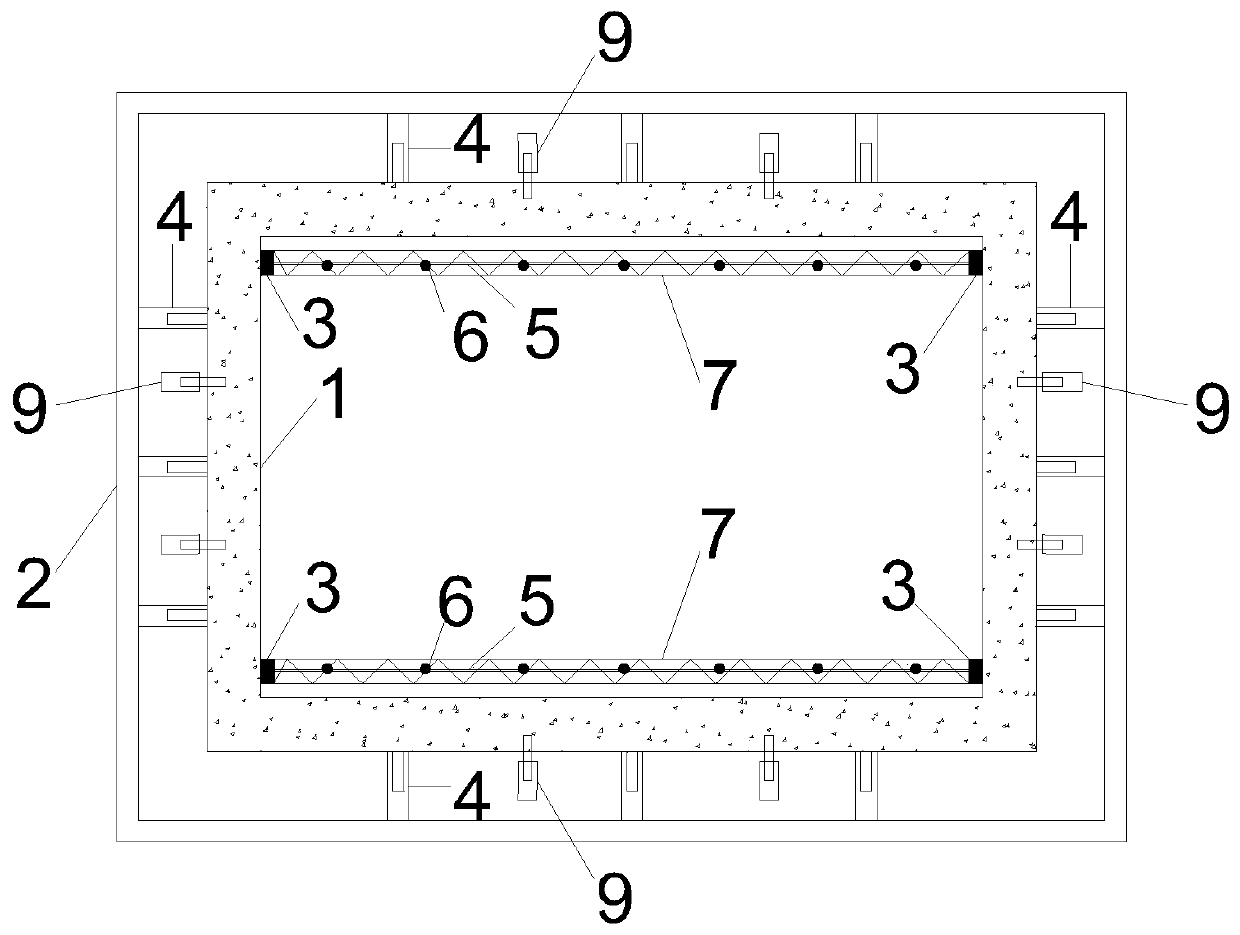

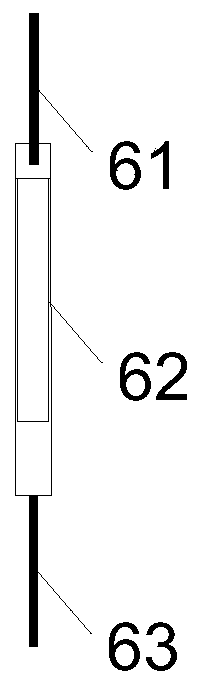

[0046] combine figure 1 with figure 2 As shown, a cable-type flexible steel platform formwork for a super high-rise building provided in this embodiment includes a steel platform 2, a steel platform overhanging corbel 9, a column support structure 3, a column corbel 10, a connecting truss 7, a top Lift oil cylinder 8, oil cylinder corbel 11, main cable 5 and some adjustable stay cables 6.

[0047] The column corbel 10 is arranged on the side of the column support structure 3 for supporting the column support structure 3 on the inner wall of the core tube shear wall 1 . The contact truss 7 is set horizontally, and the two ends are respectively fixedly connected with the column support structures 3 on both sides, such as figure 1 As shown, a horizontal connection truss 7 is provided on the top and bottom of the two column support structures 3 to provide horizontal support for the column support structures 3. If the height of the column support structures 3 is very high, it ma...

Embodiment 2

[0059] This embodiment provides a method for lifting a cable-type flexible steel platform formwork for a super high-rise building. Figure 1 to Figure 3 The promotion method is described further. The lifting method comprises the steps of:

[0060] Adjust the effective length of the adjustable cable 6 so that the adjustable cable 6 is in a stressed state, and the steel platform 2 is supported by the adjustable cable 6;

[0061] The outrigger 9 of the steel platform is withdrawn from the shear wall 1 of the core tube;

[0062] Gradually shorten the effective length of the adjustable cable 6, control the upward lifting speed of the steel platform 2, and after the steel platform 2 is lifted in place, insert the steel platform outstretched corbel 9 into the core tube shear wall 1, and the core tube shear wall 1 Provides vertical support.

[0063] Since the height of the column support structure 3 is relatively high, multiple climbing of the steel platform 2 can be realized. How...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com