Continuous casting steel ladle final pouring method based on steel flow amount comparison

A technology of passing steel quantity and continuous casting steel, which is applied in the field of continuous casting ladle final pouring based on the comparison of passing steel quantity, which can solve the problems that cannot be realized and delay the formation of vortex at the bottom of the ladle, so as to reduce the residual steel of the ladle and effectively and reasonably control the ladle The effect of slag discharge, economic benefit and production process control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

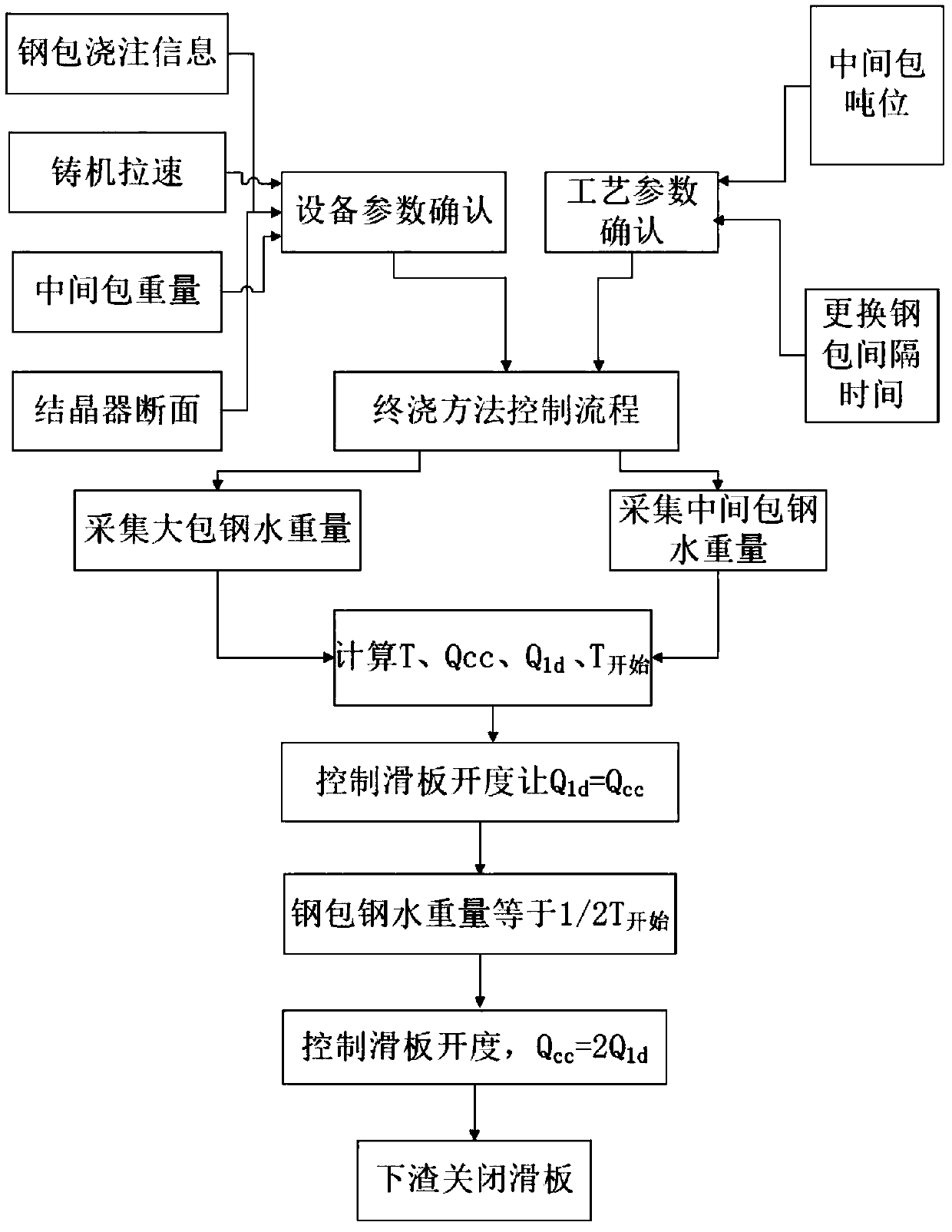

[0038] A method for final pouring of continuous casting ladles based on the comparison of the amount of passing steel, the method is implemented according to the following steps:

[0039] 1. Confirmation of equipment parameters before final pouring method control

[0040] 1.1 The equipment included in this process plan includes ladles, ladle slides, hydraulic cylinders for controlling slide mechanisms, tundishes, double-flow crystallizers, etc.;

[0041]1.2 Collect and confirm the pouring state information of the ladle as the pouring position, casting machine pulling speed information, and tundish weight information;

[0042] 1.3 Collect and confirm the status information of the hydraulic cylinder of the ladle slide mechanism;

[0043] 1.4 Collect the weight of the tundish, confirm the section size of the mold is 1200mm*230mm, and the casting speed is 1.2m / min;

[0044] 1.5 The above data collection and operation are normal, and the next optimization control is carried out; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com