Method for preventing swirling slag from metallurgical casting and device therefor

A vortex and slag rolling technology, which is applied in metal processing equipment, mechanical cleaning, manufacturing tools, etc., can solve problems such as the difficulty of accurately grasping the specific gravity and center of the cone, the complexity of the suppressor molding process, and the rise of secondary oxidation pollutants. Reaching the effect of obvious vortex slag entanglement, eliminating vortex slag entrapment phenomenon, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

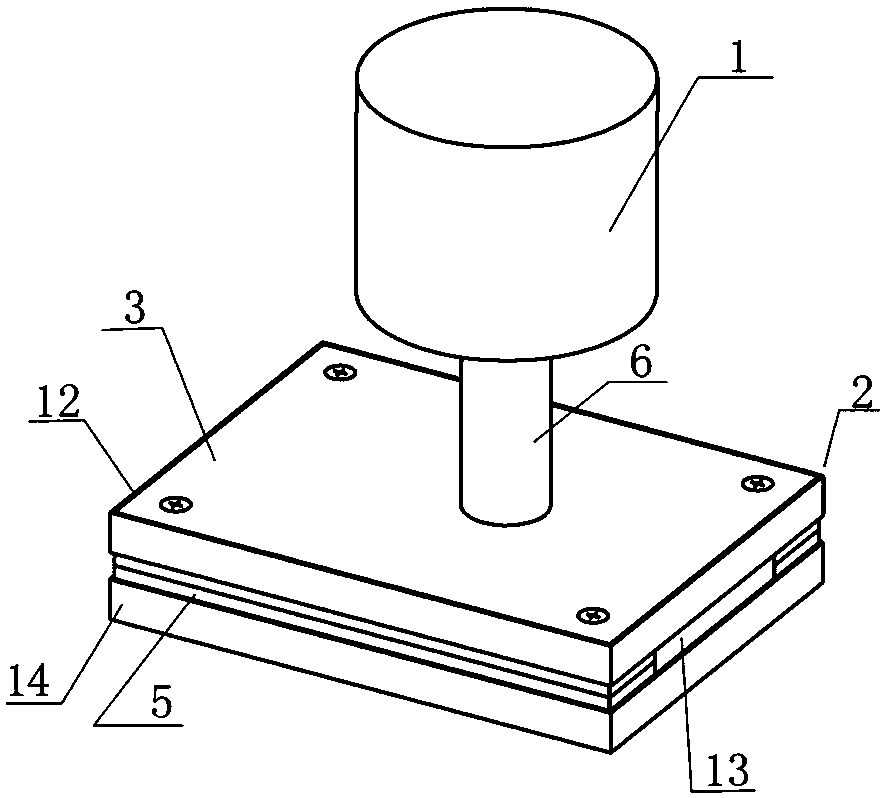

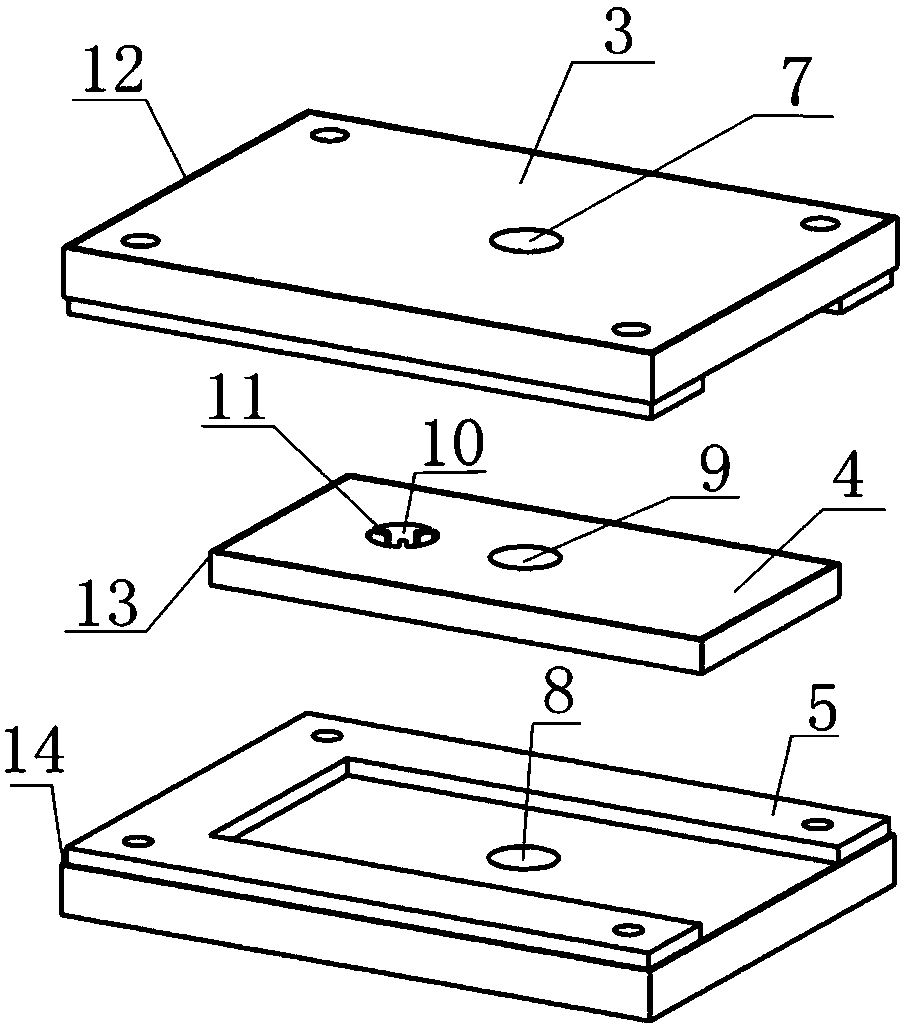

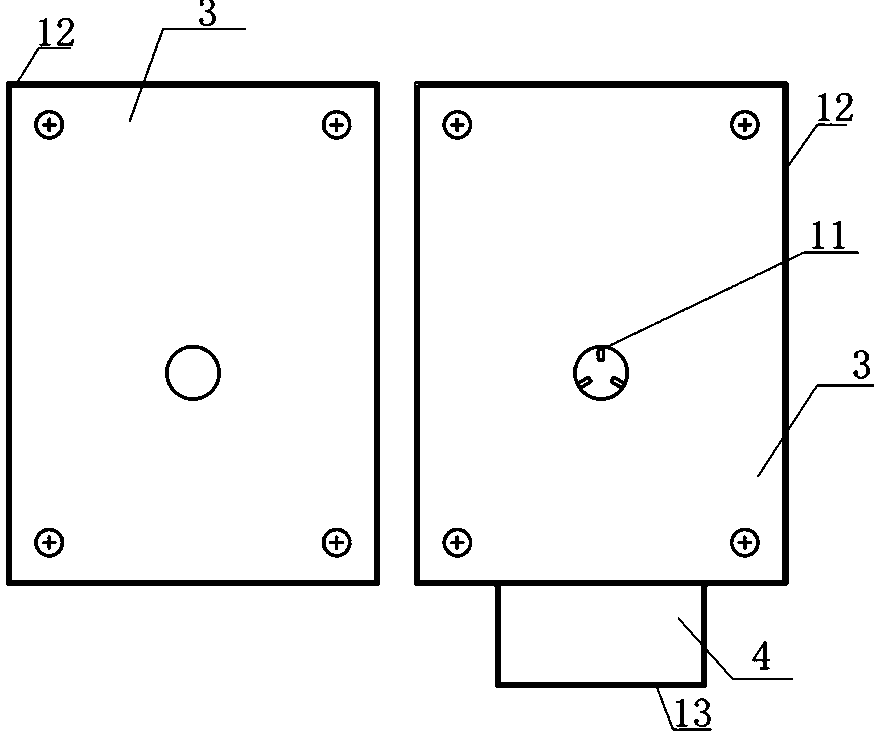

[0031] See attached Figure 1-2 , a device for preventing metallurgical reactor pouring from producing vortex slag, comprising a metallurgical reactor 1 and a pouring interface 2; the pouring interface includes an upper plate 3, a middle plate 4, and a lower plate 5; The outlet of the device is connected; the lower plate and the upper plate are connected by screws; the middle plate can slide relative to the upper plate and the lower plate; the sliding of the middle plate can be controlled by using the existing tie rod, which can be connected with the cylinder or the driver. Upper plate 3 is provided with upper plate tight hoop 12 around, middle plate 4 is surrounded with middle plate tight hoop 13, and lower plate 5 is surrounded with lower plate tight hoop 14; The thickness is 2mm, which can effectively avoid the cracking of the board, prevent the penetration of molten metal, and greatly increase the service life of the interface device. The upper plate 3 is provided with an...

Embodiment 2

[0037] The device for preventing metallurgical reactor pouring from producing vortex slag has the same structure as that of Embodiment 1, except that the second through hole 10 of the middle plate 4 is provided with 4-piece 90° arrangement of shields 11, which are symmetrically distributed, see Figure 4 ; The spacer and the middle plate are integrally formed, and the material is MgO-C; the metallurgical reactor is a continuous casting ladle.

[0038] A 250t continuous casting ladle in a steelmaking plant, the liquid level of the full ladle is 4.7m, and the diameter of the tap hole is 200mm. During the pouring of the continuous casting tundish on the continuous casting platform on the ladle, due to the limited standing time of the refining station, during the conventional pouring process , Relying on the automatic slag detection system to control the export of molten steel, the general amount of remaining steel is about 1.2t. Use the above-mentioned device for preventing vorte...

Embodiment 3

[0040] The device for preventing vortex slag from pouring in the metallurgical reactor is consistent with the structure of the first embodiment, except that the second through hole is provided with 5 pieces of baffles that are evenly distributed at 72°, the length of the baffles is 35mm, and the middle plate is relatively to the upper plate. Both the surface of the lower plate and the lower plate are provided with a lead powder layer, which is beneficial to increase the sliding of the middle plate. A 50t tundish in a steelmaking plant, with a tap hole diameter of 110mm, is used in a continuous casting crystallizer; the device for preventing metallurgical reactor pouring from producing vortex slag of the present invention is used to prevent metallurgical reactor pouring from producing vortex slag, using Example 1 In the pouring step, the vortex slag completely disappeared in the mid-term, and the amount of remaining steel was reduced by nearly 42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com