High-efficiency waste collection and transportation equipment

A garbage removal vehicle, high-efficiency technology, applied in the direction of garbage receptacle, transportation and packaging, etc., can solve the problems of reduced garbage classification effect, low cleaning and transportation efficiency, and cumbersome reclassification, so as to improve the efficiency of garbage feeding operations, The effect of reducing labor intensity and high efficiency can be turned around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are all based on figure 1 For the reference direction:

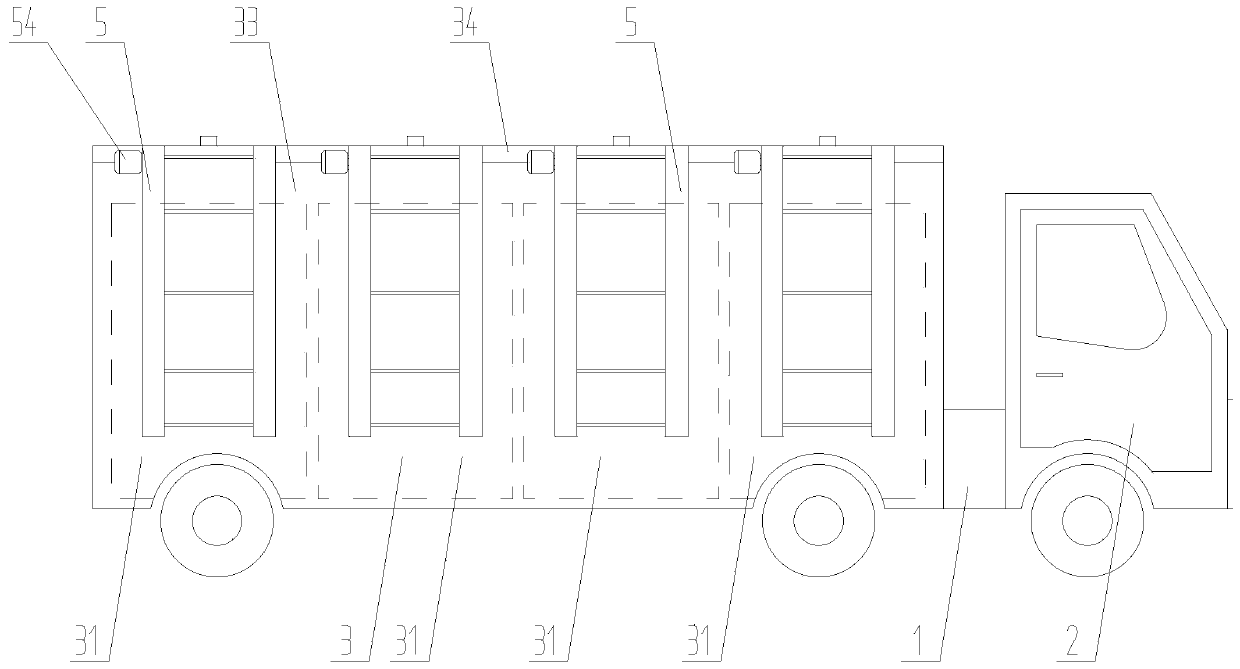

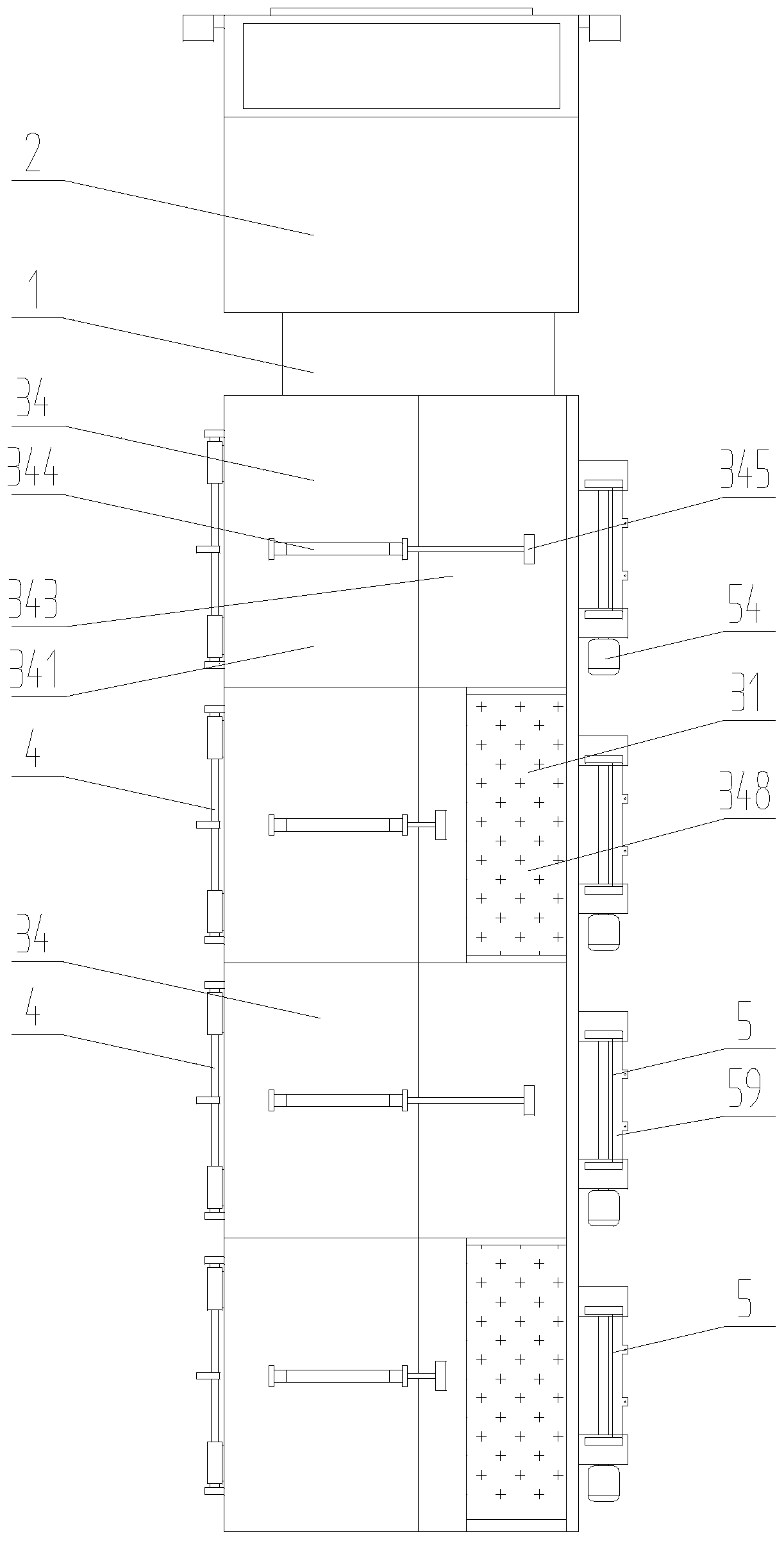

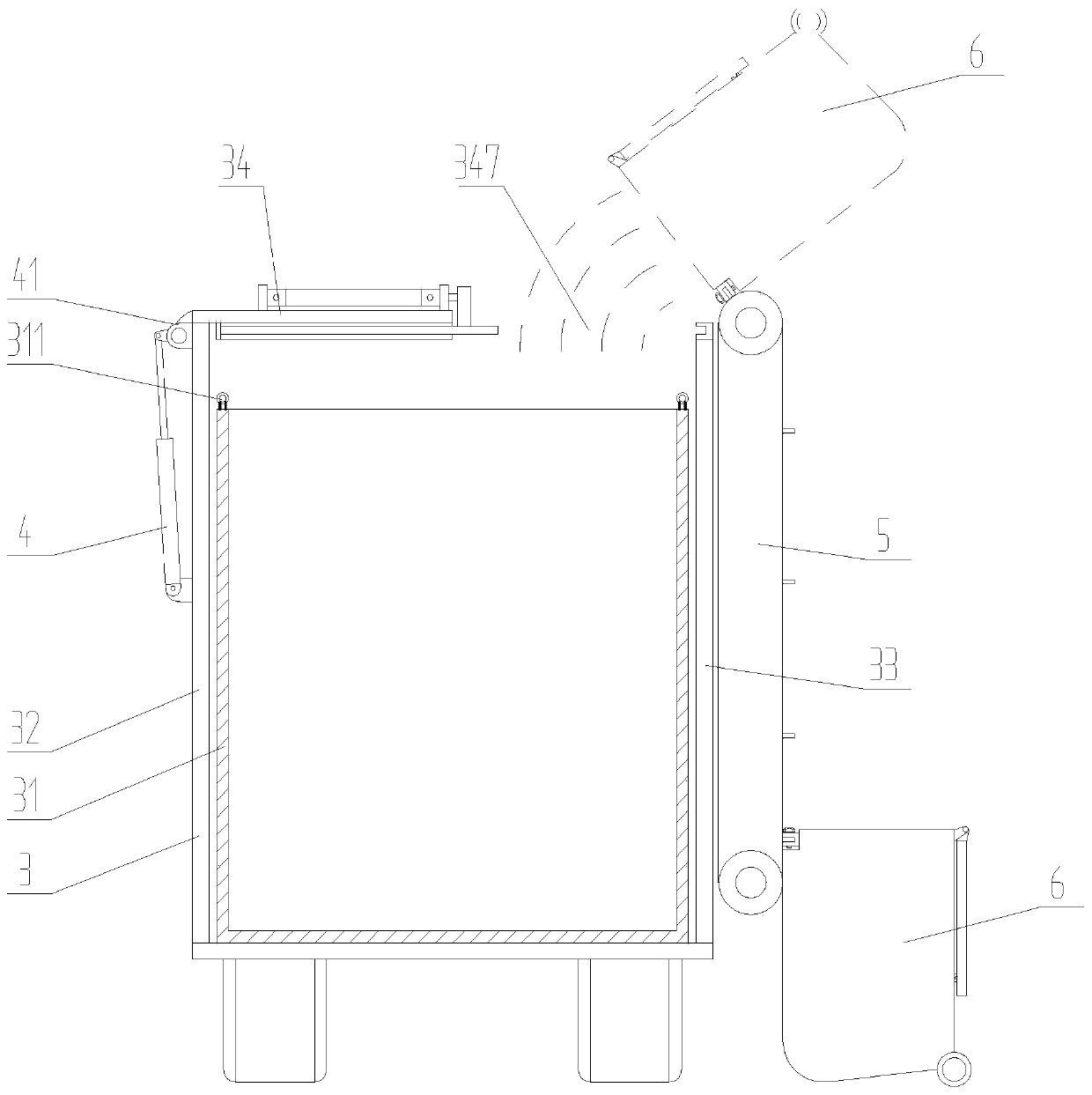

[0031] Such as Figure 1 to Figure 16 As shown, a high-efficiency garbage removal equipment includes a garbage removal vehicle 1, a top cover turning mechanism 4, and a garbage classification recovery bin device 6. The right side of the garbage removal vehicle 1 is provided with a driver's cab 2, and the garbage removal vehicle A garbage transfer compartment 3 is fixedly installed on the transport vehicle 1, and a number of garbage removal barrel assemblies 31 are placed in the garbage transfer carriage 3 for sorting and collecting garbage for removal. The garbage removal barrel assembly 31 includes a garbage removal barrel body 312 1. The bottom cover 313 of the garbage removal bucket, the bottom cover 313 of the garbage remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com