Connection structure of prefabricated assembly type laminated plates and steel beam and connection method thereof

A technology of prefabricated assembly and connection structure, which is applied to floors, building components, building structures, etc., can solve problems such as the bad influence of the connection between the prefabricated bottom plate and the steel beam, and the joint performance of the prefabricated bottom plate. Improve interoperability, reduce lateral stretch and vertical vibration damage, and shorten construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

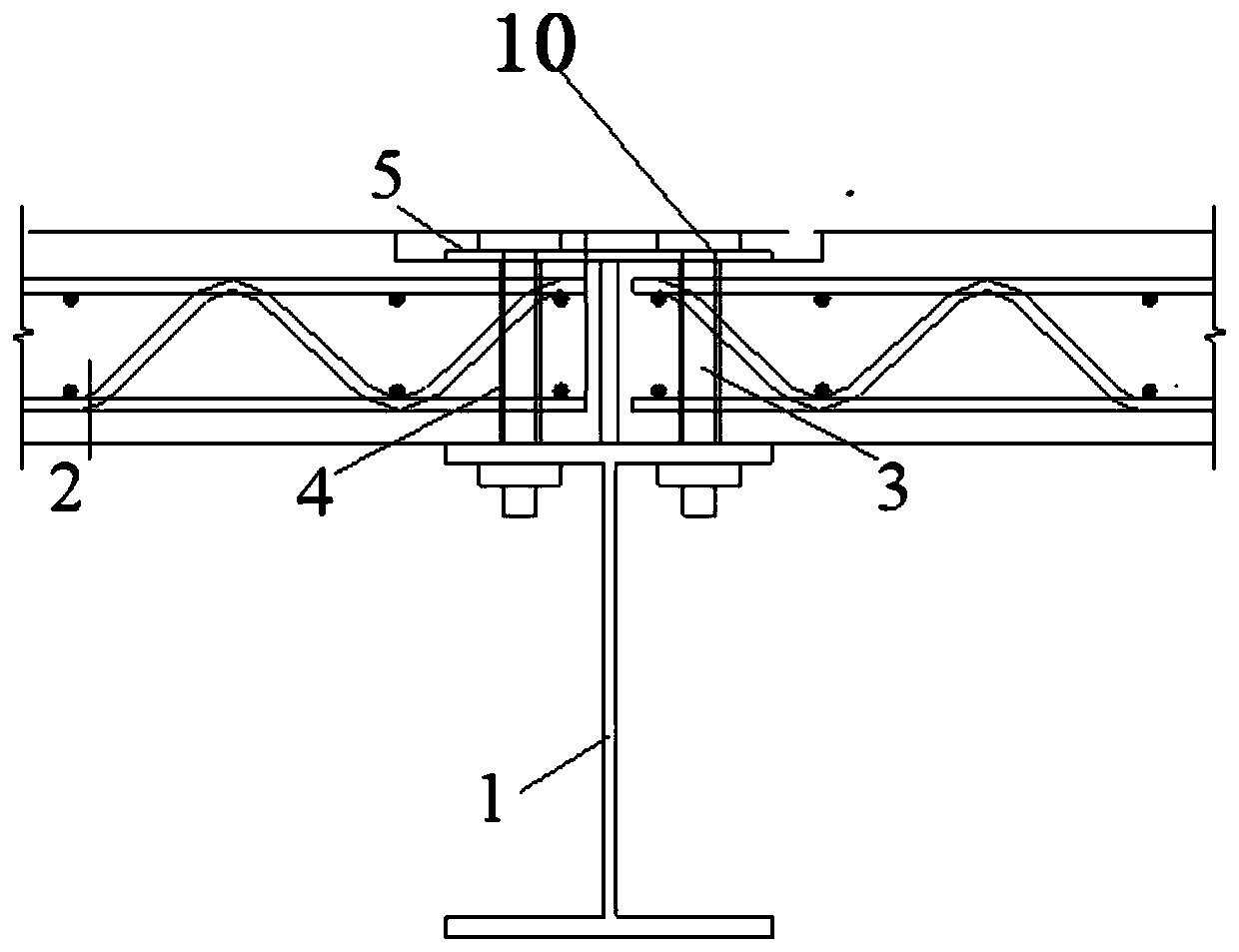

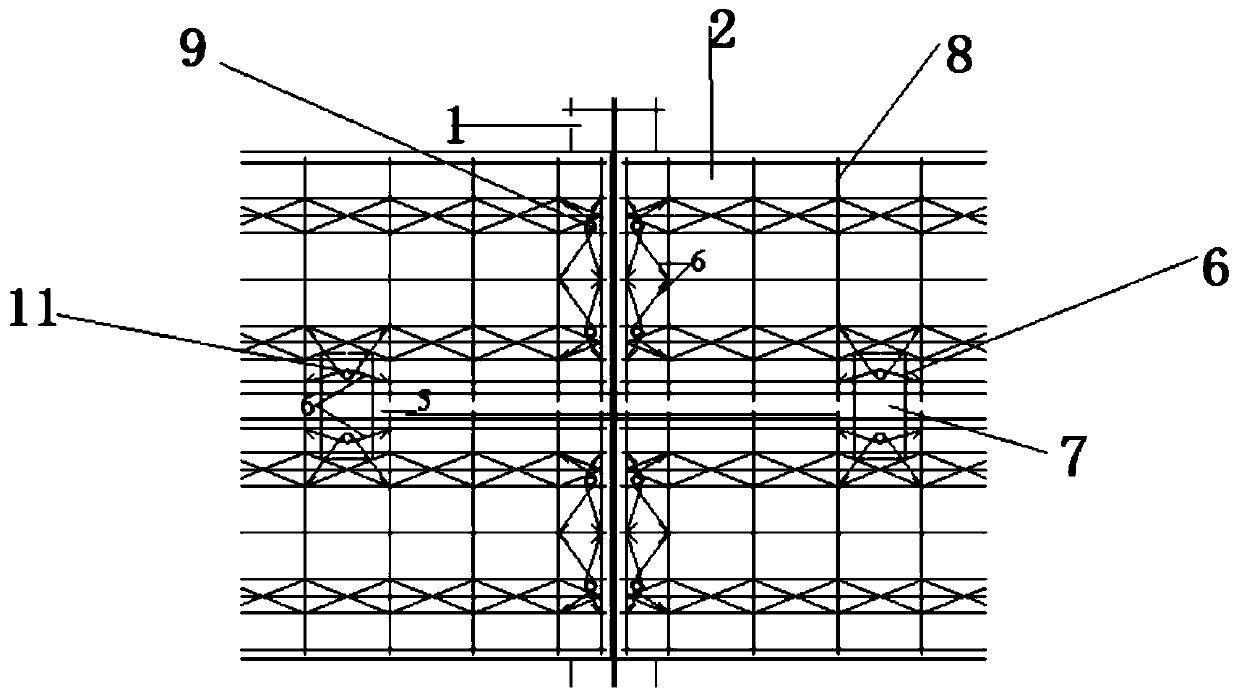

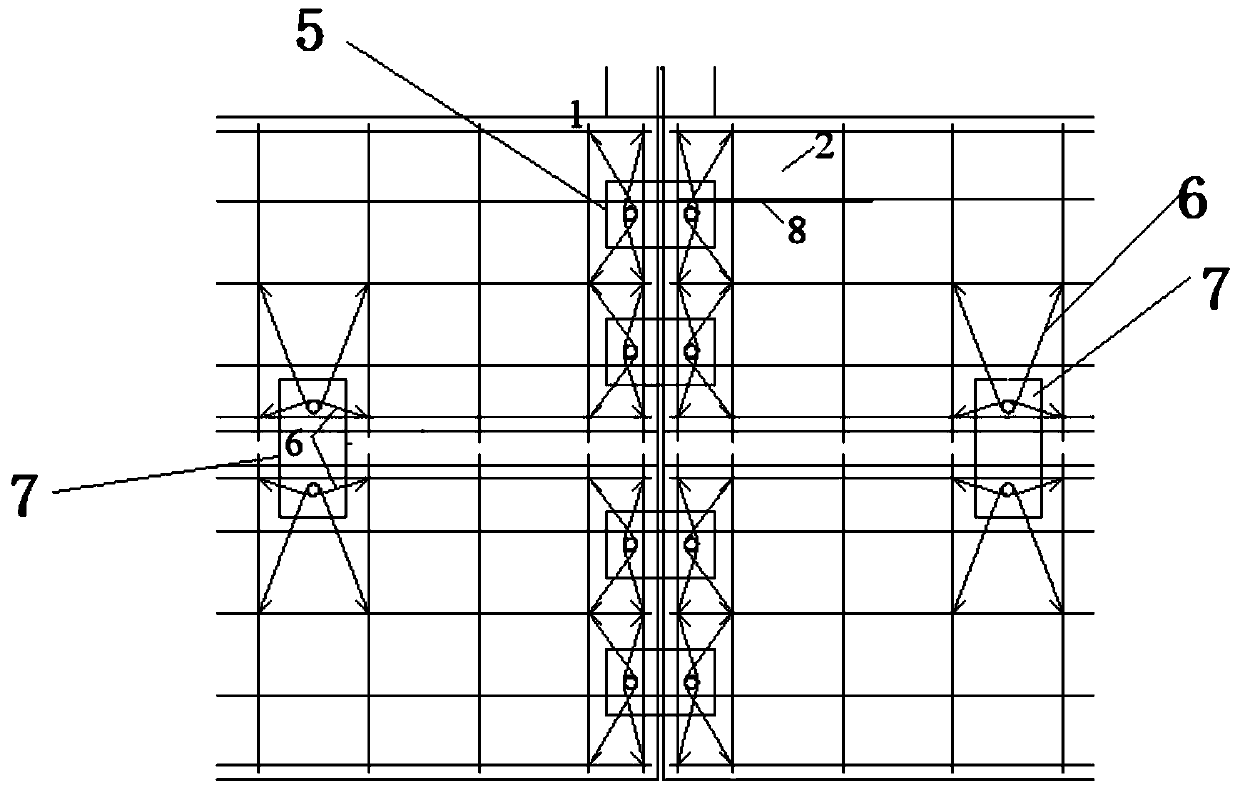

[0036] The present invention is a connection structure between a prefabricated assembled laminated plate and a steel beam, the structure of which is as follows Figure 1-3 As shown, including the I-shaped steel beam 1, the upper surface of the I-shaped steel beam 1 "I" is left-right symmetrical and fixed with a reinforced truss concrete composite plate 2 through a bolt connector 3;

[0037] The reinforced truss concrete composite slab 2 is fixed on the I-shaped steel beam 1, and one end of the I-shaped steel beam 1 is reserved with a through hole 9, and a casing 4 is anchored in the through hole 9, and the casing 4 extends out of the reinforced truss concrete composite slab 2. On the upper surface, the upper surface of two symmetrical steel bar truss concrete laminates 2 is jointly covered with a cover plate 5, and a hole 10 is opened on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com