Workbench and method for automatically overturning welding jig

A welding jig, automatic flip technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment and other directions, can solve the problems of large limitations, large welding limitations, small functions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

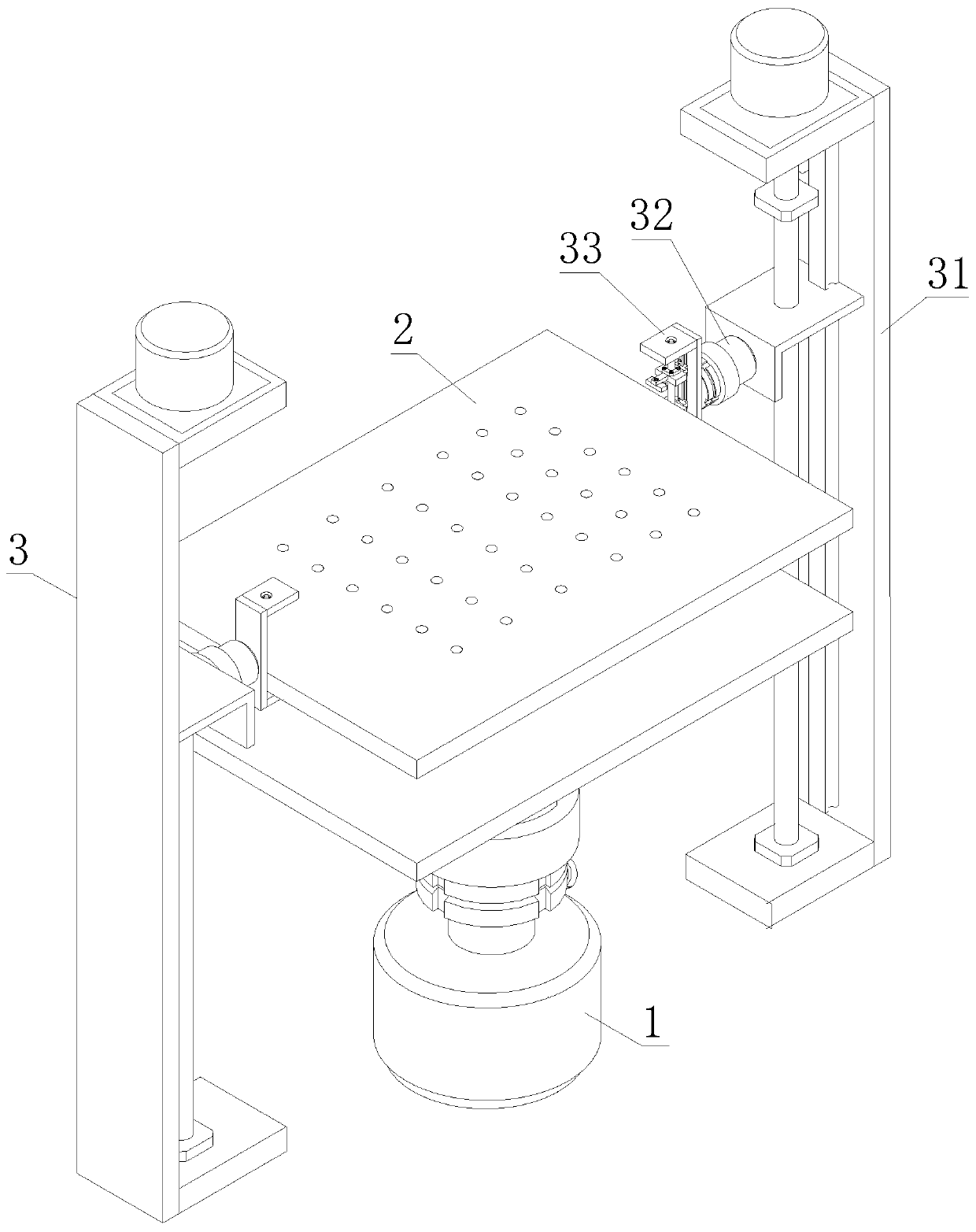

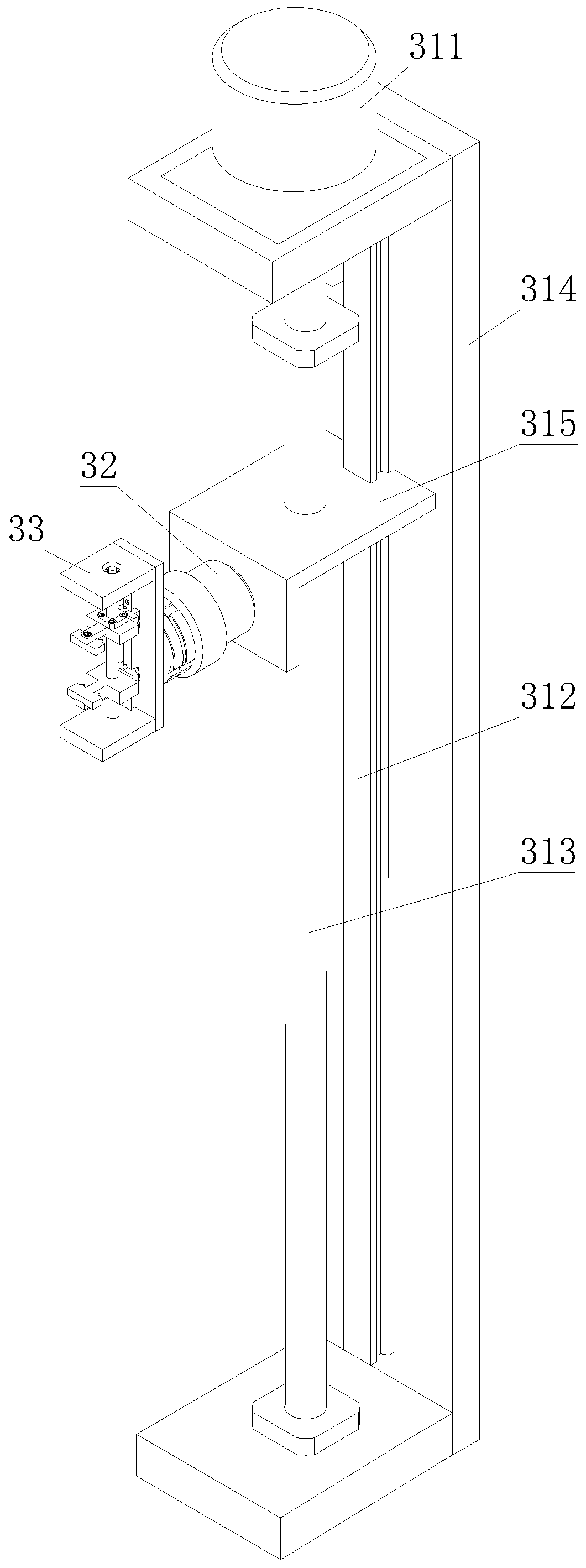

[0032] refer to figure 1 , a workbench for automatically turning over a welding fixture, comprising a base 1, a double-layer table body 2 and a turning device 3, the lower end of the double-layer table body 2 is provided with a base 1, and the two sides of the double-layer table body 2 are connected to the turning device 3 connected; the double-layer table body 2 includes a vacuum platform 21 and a horizontal platform 22, and the vacuum platform 21 and the horizontal platform 22 are parallel to each other and connected by a cylinder assembly 23; the turning device 3 includes a lifting mechanism 31, a rotating motor 32 and a clamping Mechanism 33, one end of rotating motor 32 is connected with lifting mechanism 31, and the other end is connected with clamping mechanism 33, and the middle part of clamping mechanism 33 is clamped and connected with double-layer table body 2.

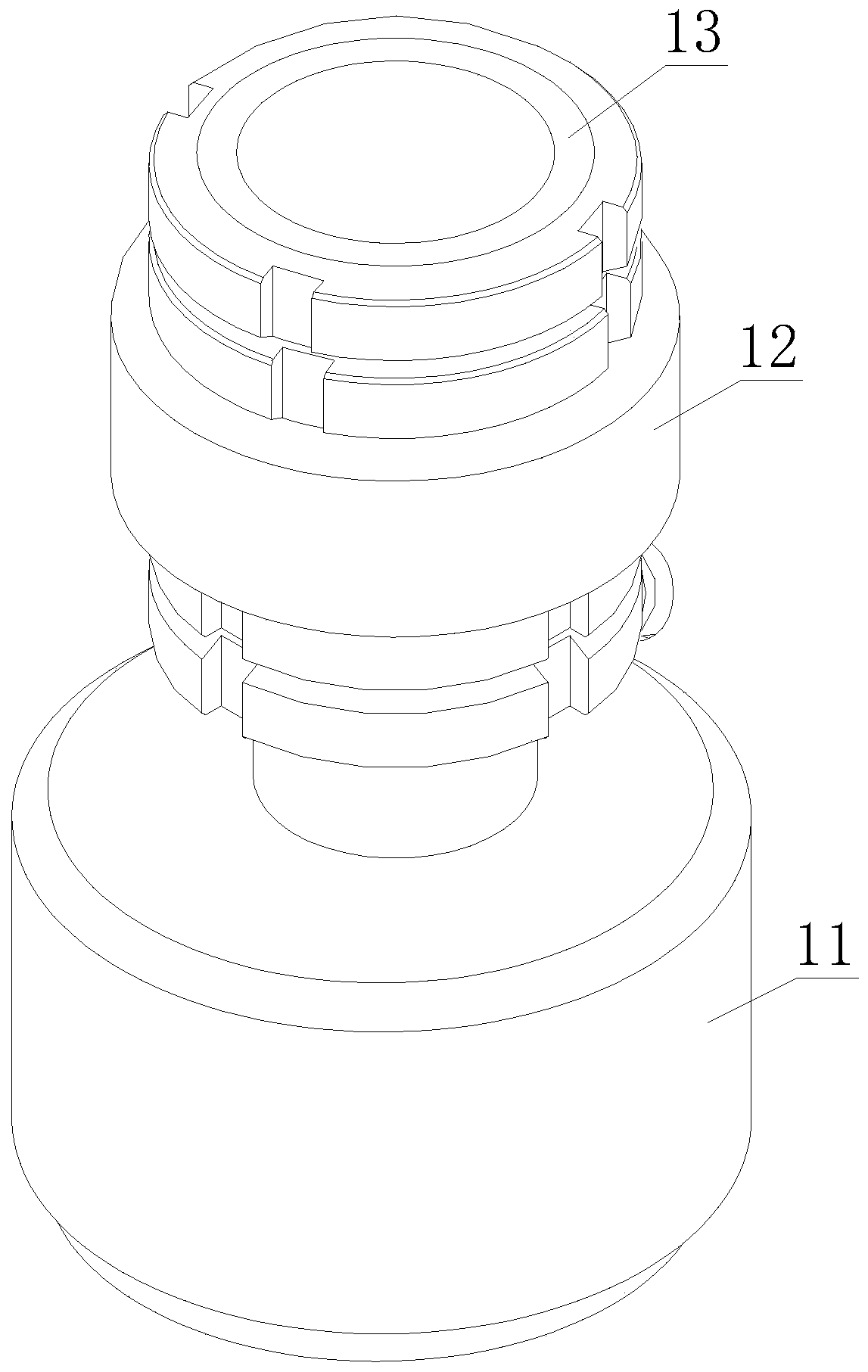

[0033] refer to figure 2 , the base 1 includes the main motor 11, the connecting block 12 and the elec...

Embodiment 2

[0046] refer to figure 1 , a workbench for automatically turning over a welding fixture, comprising a base 1, a double-layer table body 2 and a turning device 3, the lower end of the double-layer table body 2 is provided with a base 1, and the two sides of the double-layer table body 2 are connected to the turning device 3 connected; the double-layer table body 2 includes a vacuum platform 21 and a horizontal platform 22, and the vacuum platform 21 and the horizontal platform 22 are parallel to each other and connected by a cylinder assembly 23; the turning device 3 includes a lifting mechanism 31, a rotating motor 32 and a clamping Mechanism 33, one end of rotating motor 32 is connected with lifting mechanism 31, and the other end is connected with clamping mechanism 33, and the middle part of clamping mechanism 33 is clamped and connected with double-layer table body 2.

[0047] refer to figure 2 , the base 1 includes the main motor 11, the connecting block 12 and the elec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap